views

The global automotive landscape is undergoing a profound transformation as the world shifts towards cleaner, greener, and more sustainable transportation solutions. Among the key trends leading this revolution is the rapid adoption of electric vehicles (EVs). As the demand for EVs accelerates, the need for advanced materials to enhance their performance, safety, and efficiency has never been greater. One of the most critical components in this regard is insulation. The electric vehicle insulation market is projected to witness significant growth, driven by technological advancements, regulatory pressures, and the expanding EV market.

What is Electric Vehicle Insulation?

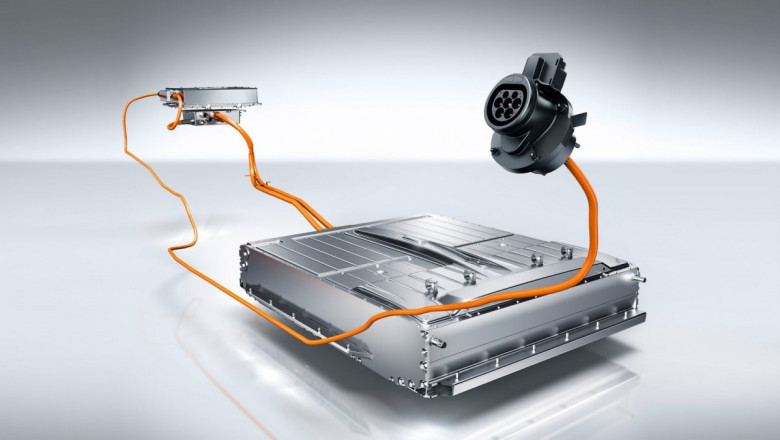

Insulation in electric vehicles plays a crucial role in protecting various vehicle systems from extreme temperatures, electrical hazards, and mechanical damage. It is used in battery packs, wiring harnesses, motors, powertrains, and other electrical components to ensure efficient operation and safety. Insulation materials help to manage the heat generated by batteries, motors, and other electrical parts, which is critical in maintaining the longevity and reliability of EVs.

Drivers of Market Growth

Several factors are contributing to the growth of the electric vehicle insulation market:

1. Rising Demand for Electric Vehicles

The global shift towards sustainability is one of the key drivers of the EV market's growth. Governments around the world are implementing stringent emission regulations and offering incentives to promote the adoption of EVs. According to the International Energy Agency (IEA), global electric car stock surpassed 10 million units in 2020, and this number is expected to grow exponentially in the coming years. This surge in EV adoption directly influences the demand for high-performance insulation materials that can improve the efficiency, safety, and overall performance of electric vehicles.

2. Increased Focus on Safety and Efficiency

Electric vehicles are complex machines with a variety of electrical systems and components that require optimal insulation. As the performance requirements of EV batteries and motors continue to evolve, insulation technologies must keep pace. The need for materials that can handle high temperatures and prevent short circuits, fires, and other hazards is driving innovations in the insulation sector. Additionally, high-quality insulation ensures efficient power delivery, reducing energy losses and maximizing driving range, which is a top priority for consumers.

3. Technological Advancements

Advancements in materials science have led to the development of new, high-performance insulation materials specifically designed for EV applications. For instance, materials such as thermally conductive polymers, high-temperature resistant foams, and ceramics are increasingly being used for insulation in EVs. These materials offer better durability, enhanced thermal management, and improved electrical insulation compared to traditional materials. This has opened up new opportunities for manufacturers to create products that meet the evolving needs of the electric vehicle market.

4. Regulatory Pressure

As governments worldwide introduce stricter emission standards, automakers are compelled to focus on energy-efficient solutions. In particular, regulations in the European Union, the United States, and China are pushing for higher levels of performance and safety in EVs. This has accelerated the demand for insulation materials that can support higher voltage batteries, improved energy efficiency, and enhanced safety standards, all while ensuring compliance with regulatory requirements.

Challenges in the Electric Vehicle Insulation Market

While the electric vehicle insulation market presents significant growth opportunities, it is not without its challenges.

1. Material Cost

The cost of high-performance insulation materials can be relatively high, particularly when compared to traditional automotive insulation materials. As a result, there may be cost pressures on manufacturers to balance performance and cost-effectiveness, especially for mass-market electric vehicles.

2. Complexity of Manufacturing Processes

The production of specialized insulation materials often involves complex processes that require precise manufacturing techniques. This can lead to longer production times and higher operational costs. Moreover, scaling up production to meet the growing demand for EVs may present logistical challenges for insulation manufacturers.

3. Supply Chain Constraints

The global supply chain for raw materials used in insulation, such as advanced polymers, metals, and ceramics, is currently facing some constraints. This has been exacerbated by recent geopolitical events and disruptions caused by the COVID-19 pandemic. Manufacturers need to navigate these challenges to ensure the timely availability of materials for the growing EV market.

Future Prospects

Despite the challenges, the electric vehicle insulation market has immense potential. With the continuous evolution of EV technology and growing consumer demand for electric mobility, the need for advanced insulation solutions will only increase. Furthermore, the rise of autonomous driving and connected vehicles is likely to introduce new applications for insulation materials in electric vehicles, creating new growth avenues.

The market is expected to expand at a compound annual growth rate (CAGR) of over 10% during the next decade, according to several market reports. Key players in the industry, including automakers, battery manufacturers, and insulation material suppliers, are investing heavily in research and development to improve the efficiency, performance, and sustainability of insulation solutions.

Conclusion

The electric vehicle insulation market holds considerable promise, driven by the accelerating adoption of electric vehicles, regulatory mandates, and advancements in insulation technologies. As the automotive industry continues to evolve, the role of insulation in ensuring the performance, safety, and sustainability of EVs will be critical. Companies that can innovate and meet the growing demands for efficient, cost-effective, and high-performance insulation solutions will be well-positioned to capitalize on this expanding market. The future of the electric vehicle insulation industry looks bright, and it will play a key role in shaping the future of transportation.

Comments

0 comment