views

Thermal fluid heaters have become crucial elements for effective heat transfer in the dynamic field of industrial heating. These systems are designed to optimize energy use and enhance operational performance across various industries. As the demand for more energy-efficient and environmentally friendly solutions grows, the next phase for high-efficiency thermal fluid heaters promises to bring about significant advancements. This blog explores the anticipated developments in thermal fluid heaters and related technologies, such as the plate heat exchanger, and their implications for the future of industrial heating.

Understanding High-Efficiency Thermal Fluid Heating Systems

Thermal fluid heaters are used to transfer heat to a fluid, which then circulates through an industrial process to provide the required thermal energy. Unlike conventional steam boilers, thermal fluid heaters operate at lower pressures and higher temperatures, making them suitable for a range of applications, from chemical processing to food production.

High-efficiency systems are characterized by their ability to maximize heat transfer while minimizing energy loss. This involves advanced design features, including improved plate heat exchangers, enhanced insulation, and precise temperature control. By focusing on these elements, high-efficiency thermal fluid heaters not only improve performance but also contribute to significant cost savings and reduced environmental impact.

Technological Innovations on the Horizon

Advanced Plate Heat Exchanger Designs

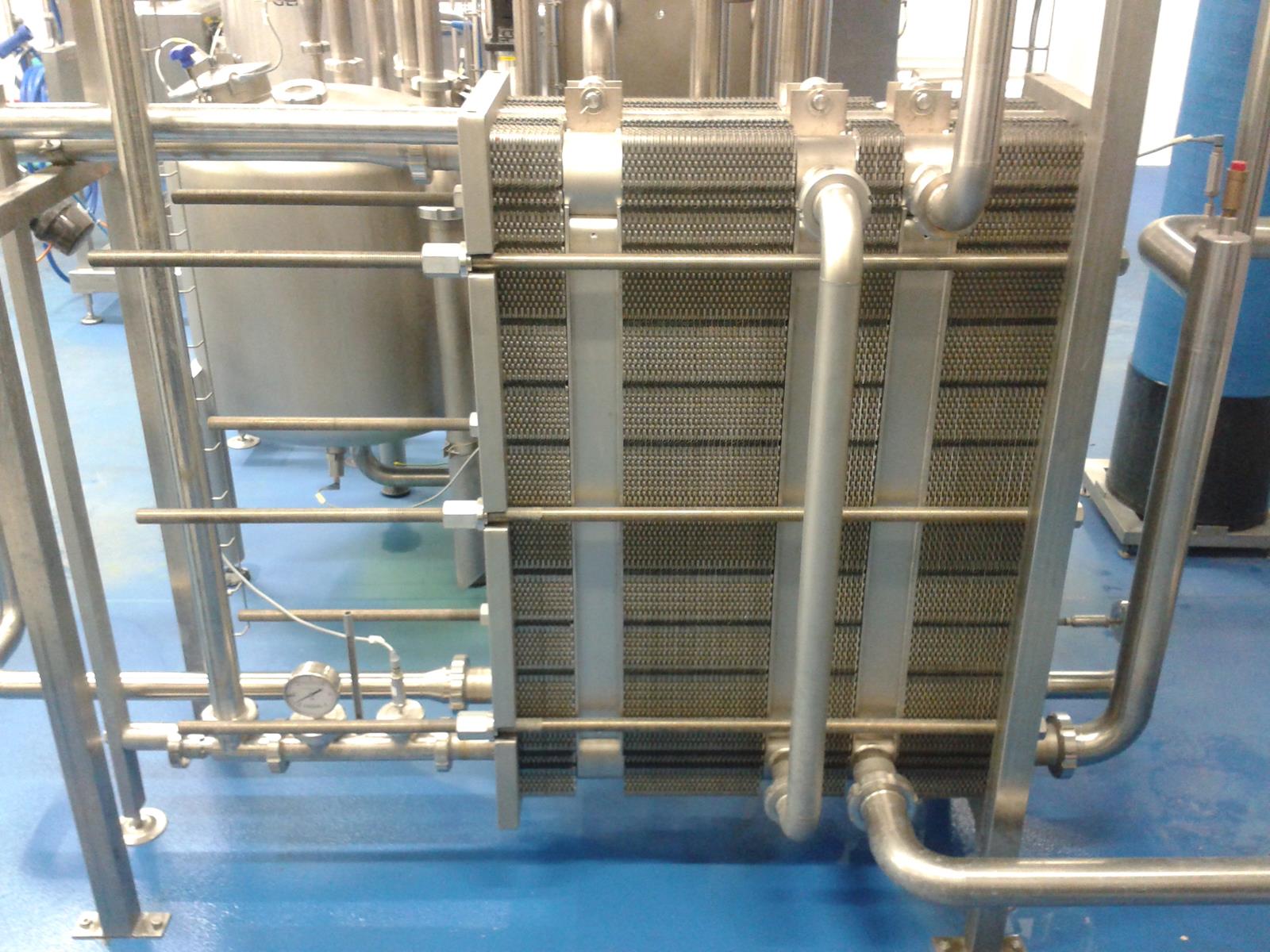

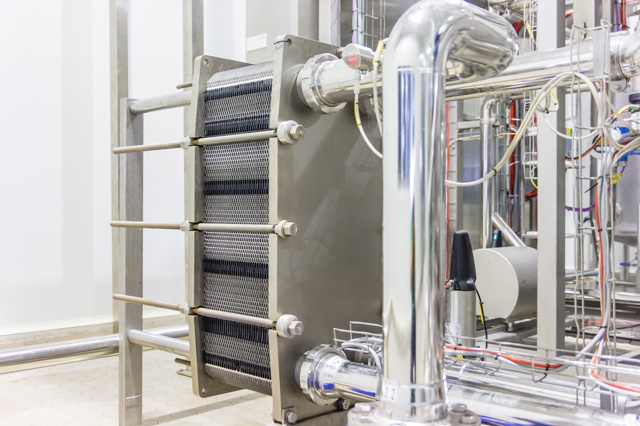

The plate heat exchanger is a critical component in many high-efficiency thermal fluid heaters. Innovations in plate heat exchanger design are expected to drive the next phase of heating system advancements. New designs focus on increasing heat transfer efficiency and reducing the overall size of the units. By employing advanced materials and optimizing plate configurations, these new plate heat exchangers can enhance the thermal performance of thermal fluid heaters, leading to more compact and efficient systems.

Integration of Smart Technologies

The integration of smart technologies into thermal fluid heaters is poised to revolutionize their operation and maintenance. Advanced sensors, IoT connectivity, and automated control systems will enable real-time monitoring and adjustments. This will allow for more precise control of temperature and pressure, improving system efficiency and reliability. Remote monitoring capabilities will also enable operators to manage systems from anywhere, enhancing operational flexibility and reducing downtime.

Development of Eco-Friendly Fluids

Environmental sustainability is a growing concern in industrial operations. The development of new, eco-friendly thermal fluids is a key focus for the future of thermal fluid heaters. These fluids are designed to be more sustainable, with lower environmental impact while maintaining high performance. The shift towards using greener fluids aligns with global sustainability goals and helps industries meet stricter environmental regulations.

Operational Improvements and Best Practices

Enhanced Energy Efficiency

Energy efficiency remains a top priority for high-efficiency thermal fluid heaters. Advances in burner technology, improved insulation materials, and optimized combustion control systems are driving improvements in energy efficiency. By reducing fuel consumption and operational costs, these advancements make high-efficiency systems more cost-effective and environmentally friendly. Regular maintenance and performance tuning are essential to ensure that systems continue to operate at peak efficiency.

Improved Safety Features

Safety is a critical aspect of thermal fluid heaters due to the high temperatures and pressures involved. Future developments are likely to include enhanced safety features, such as advanced leak detection systems, robust pressure relief mechanisms, and improved control systems. These features will help prevent accidents and ensure safe operation, providing operators with greater peace of mind and reducing the risk of costly downtime.

Streamlined Maintenance Processes

Effective maintenance is crucial for the longevity and performance of thermal fluid heaters. The next phase of high-efficiency systems will likely focus on simplifying maintenance processes through modular designs and automated diagnostic tools. These innovations will make it easier to access and service components, reducing maintenance time and costs. Preventive maintenance strategies will also be emphasized to address potential issues before they escalate, ensuring continuous and efficient operation.

The Role of High-Efficiency Thermal Fluid Heating Systems in the Future

Supporting Sustainable Industrial Practices

As industries increasingly prioritize sustainability, high-efficiency thermal fluid heaters play a pivotal role. By improving energy efficiency and reducing emissions, these systems contribute to the overall sustainability of industrial operations. The adoption of eco-friendly thermal fluids and advanced technologies further enhances their environmental benefits, helping industries align with global efforts to reduce carbon footprints and combat climate change.

Enhancing Industrial Competitiveness

The next phase of high-efficiency thermal fluid heaters will have a significant impact on industrial competitiveness. By lowering energy costs and improving operational efficiency, these systems can help businesses maintain a competitive edge in a challenging market. Enhanced reliability and reduced maintenance costs will also contribute to the overall cost-effectiveness of industrial heating processes.

Meeting Regulatory Requirements

Stricter environmental regulations and energy efficiency standards are driving the development of high-efficiency thermal fluid heaters. As regulations evolve, industries will need to adopt advanced heating technologies to remain compliant. High-efficiency systems will be essential for meeting these standards and avoiding potential penalties, ensuring that businesses can operate within the legal framework and contribute to environmental sustainability.

Conclusion

The future of high-efficiency thermal fluid heaters is marked by significant advancements in technology, operational efficiency, and environmental sustainability. Innovations in plate heat exchangers, smart technologies, and eco-friendly fluids are set to shape the next phase of industrial heating systems. By focusing on these areas, industries can achieve greater energy efficiency, cost savings, and sustainability, ensuring that their heating systems are well-equipped to meet the demands of the future. As these technologies continue to evolve, high-efficiency thermal fluid heaters will remain at the forefront of industrial heating solutions, driving progress and innovation across various sectors.

Comments

0 comment