views

Predictive Maintenance Market Overview:

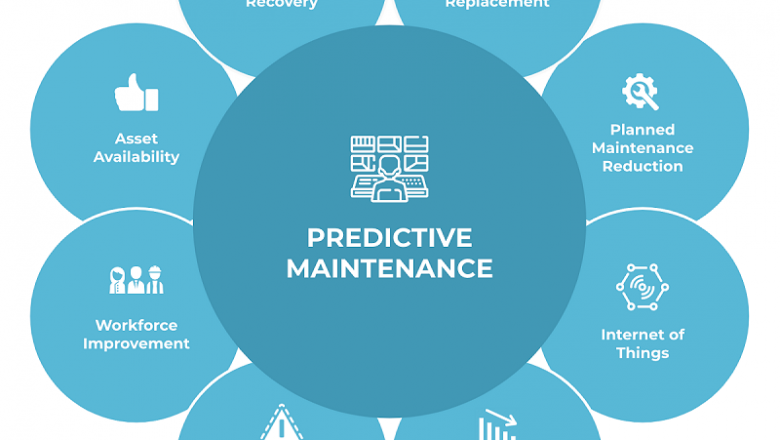

The predictive maintenance market has gained significant traction in recent years, driven by the increasing need for organizations to optimize their operational efficiency and reduce downtime. Predictive maintenance refers to the use of advanced analytics and data-driven techniques to predict when equipment failures might occur, allowing businesses to perform maintenance activities just in time to prevent unexpected breakdowns. This proactive approach not only enhances asset longevity but also minimizes costs associated with unplanned maintenance and production halts. The Predictive Maintenance Market was valued at approximately $21.83 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of around 26.20% from 2024 to 2030, reaching an estimated value of over $20 billion by the end of the forecast period. The rapid adoption of IoT devices, machine learning algorithms, and big data analytics are key factors propelling this market forward.

Market Key Players:

Several key players dominate the predictive maintenance landscape, each contributing unique technologies and solutions that enhance predictive capabilities. Major companies include IBM Corporation, Siemens AG, General Electric Company, Schneider Electric SE, and Honeywell International Inc. These organizations leverage their extensive experience in industrial automation and data analytics to provide comprehensive predictive maintenance solutions tailored for various sectors such as manufacturing, energy, transportation, and healthcare. Additionally, emerging players like Uptake Technologies Inc., PTC Inc., and Augury are gaining prominence by offering innovative software platforms that integrate seamlessly with existing systems to deliver real-time insights into equipment health.

Get PDF Sample Report + All Related Table and Graphs:

https://www.marketresearchfuture.com/sample_request/2377

Market Segmentation:

The predictive maintenance market can be segmented based on component type, deployment mode, organization size, industry verticals, and region. By component type, the market is divided into solutions (software) and services (consulting and support). In terms of deployment mode, it includes cloud-based solutions and on-premises installations. Organizations of all sizes small & medium enterprises (SMEs) and large enterprises are adopting predictive maintenance strategies; however, large enterprises tend to invest more heavily due to their complex operations. Industry verticals encompass manufacturing, oil & gas, energy & utilities, transportation & logistics, healthcare, aerospace & defense among others. Each segment presents unique challenges and opportunities for implementing predictive maintenance technologies.

Market Opportunities:

The growing emphasis on digital transformation across industries presents substantial opportunities for the predictive maintenance market. As organizations increasingly adopt Industry 4.0 principles characterized by smart factories equipped with interconnected devices—the demand for sophisticated predictive analytics tools is expected to surge. Furthermore, advancements in artificial intelligence (AI) and machine learning are enhancing the accuracy of predictive models by enabling systems to learn from historical data patterns continuously. This evolution opens new avenues for developing customized solutions that cater specifically to industry needs while improving operational efficiencies significantly.

Market Drivers:

Several factors are driving the growth of the predictive maintenance market. Firstly, the rising costs associated with unplanned downtime compel organizations to seek more reliable maintenance strategies that can mitigate these risks effectively. Secondly, regulatory compliance requirements in sectors such as healthcare and energy necessitate stringent monitoring of equipment performance; thus driving investments in predictive technologies that ensure adherence to safety standards. Additionally, the proliferation of IoT devices facilitates real-time data collection from machinery which feeds into advanced analytical models used for predicting failures before they occur.

Regional Analysis:

Geographically speaking, North America holds a significant share of the predictive maintenance market due primarily to its early adoption of advanced technologies coupled with a robust industrial base comprising numerous manufacturing facilities seeking efficiency improvements through automation solutions. Europe follows closely behind as industries across Germany and France increasingly embrace digital transformation initiatives aimed at optimizing production processes through data-driven insights. Meanwhile, Asia-Pacific is anticipated to witness rapid growth owing largely to expanding industrial sectors in countries like China and India where investments in smart manufacturing practices are on the rise.

Industry Updates:

Recent developments within the predictive maintenance sector indicate a trend toward greater integration between AI technologies and traditional industrial practices. For instance, partnerships between technology firms specializing in AI-driven analytics platforms and established industrial manufacturers are becoming commonplace as companies seek holistic solutions that combine hardware with intelligent software capabilities for enhanced decision-making processes regarding equipment management. Moreover, ongoing research into edge computing is likely set to revolutionize how data is processed locally at machines rather than relying solely on centralized cloud systems; this shift could lead not only towards faster response times but also improved security measures against potential cyber threats targeting critical infrastructure.

Browse In-depth Market Research Report:

https://www.marketresearchfuture.com/reports/predictive-maintenance-market-2377

Contact Us:

Market Research Future (Part of Wantstats Research and Media Private Limited)

99 Hudson Street, 5Th Floor

New York, NY 10013

United States of America

+1 628 258 0071 (US)

+44 2035 002 764 (UK)

Comments

0 comment