views

Introduction:

The electric vehicle (EV) industry has been experiencing exponential growth in recent years, with advancements in technology driving the transition toward a more sustainable future. One key area of focus within the Electric Vehicle Battery Swapping Market. The concept of EV battery swapping has emerged as a promising solution to address some of the challenges related to EVs, such as long charging times and limited range. As the demand for EVs increases, especially in heavy-duty sectors like logistics, battery swapping has the potential to revolutionize the way goods are transported and how fleets of heavy-duty electric trucks operate. In this article, we will explore the market for EV battery swapping and dive deep into the specific benefits and challenges of adopting this technology for heavy-duty vehicles.

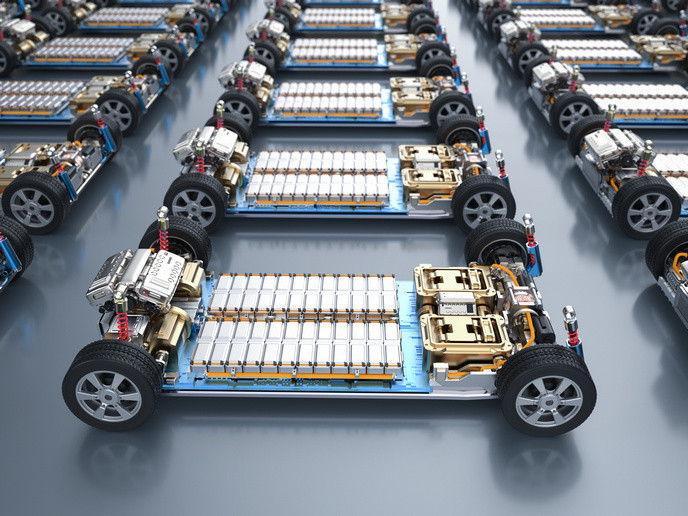

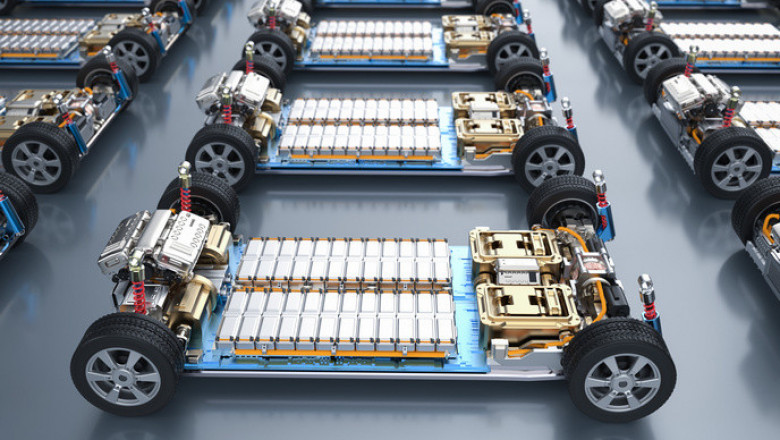

Understanding EV Battery Swapping

EV battery swapping is a method where the depleted battery of an electric vehicle is replaced with a fully charged one at a dedicated swapping station. This is in contrast to traditional charging methods, where vehicles must be plugged into charging stations and wait for their batteries to recharge. The core advantage of battery swapping is the drastic reduction in downtime. While charging an EV can take hours (depending on the battery capacity and charger type), swapping the battery takes just a few minutes, making it an attractive option for businesses that rely on fleet vehicles.

Battery swapping can be seen as a complementary technology alongside fast-charging solutions, offering an alternative to the challenges of charging infrastructure, especially in sectors requiring continuous operations, such as logistics and transportation.

EV Battery Swapping Market: Key Growth Drivers

The global EV battery swapping market is witnessing significant growth, driven by several key factors:

- Demand for EVs: With an increasing global push toward decarbonization, the adoption of electric vehicles is on the rise. Governments worldwide are providing incentives and regulatory measures to encourage the shift from traditional combustion engines to electric-powered vehicles. This growing demand for electric vehicles directly boosts the need for robust charging and battery swapping infrastructure.

- Logistics and Fleet Operations: The logistics and transportation sectors are among the largest consumers of energy, with fleets of trucks and delivery vehicles traveling long distances every day. The shift to electric trucks has the potential to drastically reduce emissions and operational costs. However, long charging times can hinder operational efficiency. This is where battery swapping could prove transformative, especially for fleets operating heavy-duty electric trucks.

- Technological Advancements: Innovations in battery technology, coupled with improved battery design, are making battery swapping more feasible and cost-effective. The development of standardized battery swapping models and faster swapping systems is contributing to the increasing popularity of the technology.

4. Infrastructure Development: The development of battery swapping stations in key locations, such as logistics hubs, distribution centers, and along highways, is critical for the expansion of this market. These stations enable rapid battery exchanges for fleets of electric vehicles, ensuring minimal downtime and improving the overall efficiency of operations.

5. Environmental Regulations and Sustainability: Stricter environmental regulations aimed at reducing greenhouse gas emissions and improving air quality are pushing industries to adopt cleaner technologies. The logistics sector, which has traditionally been a significant contributor to carbon emissions, is under pressure to transition to electric vehicles. Battery swapping offers an efficient way to ensure fleet vehicles are always ready for operation, even with the challenges of long charging times.

EV Battery Swapping for Heavy-Duty Vehicles: Revolutionizing Logistics

The logistics industry is at the forefront of adopting electric vehicles for freight transport. However, heavy-duty electric trucks face unique challenges that make them less attractive compared to conventional diesel-powered trucks. These challenges include:

- Long Charging Times: Charging a heavy-duty electric truck using standard charging stations can take several hours, which can result in significant downtime.

- Limited Range: Even though the range of electric trucks has been improving, they still tend to have a lower range than their diesel counterparts, which limits their ability to travel long distances without frequent recharging.

- Infrastructure Costs: Building a comprehensive charging network for heavy-duty vehicles can be expensive, especially when compared to smaller passenger EV charging stations.

This is where EV battery swapping comes into play, offering a solution to these problems by providing a quick and efficient alternative to charging.

How EV Battery Swapping Works for Heavy-Duty Vehicles

The process of battery swapping for heavy-duty electric vehicles is similar to that of light-duty electric vehicles. Heavy-duty trucks, equipped with modular and standardized battery packs, enter a battery swapping station where their depleted battery is replaced with a fully charged one. These swapping stations are strategically located along major highways and logistics hubs to ensure maximum accessibility for truck fleets. Once the truck enters the swapping station, the entire process—from battery extraction to installation of the new battery—can be completed in a matter of minutes.

Key Benefits of EV Battery Swapping for Heavy-Duty Vehicles

- Reduced Downtime: The most obvious benefit of battery swapping is the reduction in downtime. For logistics companies, time is money. Every minute that a vehicle spends out of operation due to battery charging is a loss of productivity. With battery swapping, heavy-duty trucks can be back on the road in a fraction of the time it would take to charge the battery.

- Extended Range: By eliminating the need for long charging times, battery swapping effectively removes one of the major limitations of heavy-duty electric trucks—range anxiety. Fleet operators can rest assured that their vehicles will always have a fully charged battery, allowing them to cover longer distances without interruption.

- Infrastructure Flexibility: Battery swapping stations can be developed relatively quickly compared to traditional charging stations, and they do not require the same high-power electrical infrastructure. This makes it easier to scale up and deploy a network of swapping stations across regions where logistics operations are most concentrated.

- Cost Savings for Fleet Operators: Battery swapping offers the potential for significant cost savings for fleet operators. Instead of purchasing expensive electric batteries for each vehicle and incurring the ongoing costs of battery maintenance, fleet operators can lease batteries and only pay for the energy consumed during each swap. This lowers the upfront costs of transitioning to electric trucks and helps manage operational expenses more efficiently.

- Faster Turnaround Times: For logistics companies that operate on tight schedules and need to ensure timely deliveries, battery swapping helps achieve faster turnaround times. A few minutes spent at a swapping station is far less disruptive than a long charging period, keeping goods moving and ensuring consistent operations.

- Battery Lifecycle Management: Battery swapping stations can also play a role in battery lifecycle management, allowing for the efficient recycling, refurbishing, or repurposing of batteries. As batteries age, their performance degrades. Swapping stations can track the condition of each battery and ensure that only the best-performing batteries are in circulation, while older ones are retired, recycled, or repurposed.

Challenges and Barriers to Adoption

While the potential for EV battery swapping in the heavy-duty logistics sector is clear, there are still some challenges that need to be addressed:

- Standardization of Battery Designs: One of the main hurdles to widespread adoption of battery swapping for heavy-duty trucks is the lack of standardized battery designs. Electric vehicle manufacturers use different battery architectures, which makes it difficult for a single swapping station to cater to all vehicles. There is a need for collaboration among manufacturers and regulatory bodies to establish industry-wide standards for battery sizes, connectors, and other specifications.

- High Initial Investment: Setting up battery swapping stations, especially in remote locations, requires significant capital investment. These stations need to be equipped with the necessary infrastructure, including robotic arms and automated systems for battery extraction and installation, as well as energy storage systems to ensure a reliable supply of fully charged batteries.

- Logistics and Supply Chain Coordination: Efficiently managing the logistics of battery swapping requires a complex supply chain to ensure that enough fully charged batteries are available at each station. This involves sophisticated inventory management and coordination to prevent any disruption in operations.

- Regulatory and Safety Standards: The adoption of battery swapping requires compliance with stringent safety regulations and standards. Each swapping station must ensure that batteries are handled, stored, and transported safely to prevent accidents or failures.

The Future of EV Battery Swapping in Logistics

As the market for electric vehicles continues to grow, so too will the demand for battery swapping solutions. Several major players in the electric vehicle and energy industries are already exploring and investing in battery swapping technologies. For instance, companies like NIO and Tesla have already implemented battery swapping stations for passenger EVs, and similar models are being tested for heavy-duty trucks.

The future of EV battery swapping in logistics looks promising, especially as governments and businesses increasingly focus on sustainable transportation solutions. With the ongoing development of standardized battery systems, improvements in swapping station technology, and growing infrastructure investment, battery swapping could become an integral part of the logistics ecosystem.

Conclusion

EV battery swapping has the potential to be a game changer for heavy-duty vehicles, particularly in the logistics sector. By addressing the key challenges of long charging times, limited range, and operational inefficiencies, battery swapping could revolutionize the way goods are transported, making logistics operations faster, more efficient, and more sustainable. As the market for electric vehicles continues to evolve, it is likely that battery swapping will play a central role in ensuring the seamless integration of electric trucks into the logistics industry.

Comments

0 comment