views

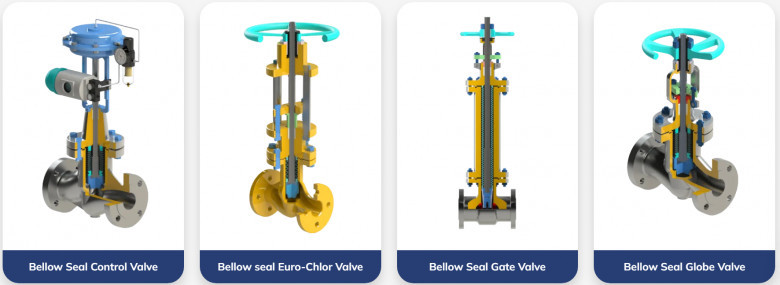

External Stem Bellow Seal Globe and Gate Valves See Surge in Industrial Demand

Mumbai, India — As global industries confront tightening emission norms and rising demands for operational safety, a new generation of valves is stepping into the spotlight. External Stem Bellow Seal Globe and Gate Valves are being rapidly adopted across sectors such as petrochemicals, pharmaceuticals, and power generation—marking a pivotal shift in how industries manage toxic and high-pressure media.

Engineered to eliminate fugitive emissions, these valves feature a fully welded metallic bellow that creates a hermetic seal, preventing any leak from the stem area—a traditional weak point in conventional valves. The external stem design offers visible operational movement, allowing plant personnel to easily monitor valve status in real time.

“As regulatory pressure increases worldwide, industries can no longer afford emission-related risks. The adoption of bellow seal valves is not just a compliance measure—it’s a commitment to safety and sustainability,” said a spokesperson from Freture Techno Pvt. Ltd., one of India’s leading valve manufacturers.

Key Configurations Now in Focus

-

Globe Valve Design – Offers precise throttling and flow control, ideal for process-critical systems.

-

Gate Valve Configuration – Suited for full shut-off needs with minimal pressure loss.

Both versions are engineered with multi-ply stainless steel bellows, backed by a secondary gland seal for fire-safe protection in case of bellow fatigue.

What’s Driving the Shift?

The increased uptake is being fueled by several standout advantages:

-

Zero Leakage Performance – Compliant U.S. EPA fugitive emission standards.

-

Visual Stem Indication – Helps operators ensure safe and accurate valve positioning, even from a distance.

-

Custom Materials & Sizes – Available in stainless steel, Hastelloy, Inconel, and other alloys, with sizes ranging from DN15 to DN300.

Industries Leading the Adoption Curve

-

Refineries & Petrochemical Facilities – Where hydrocarbon containment is mission-critical.

-

Pharmaceutical Manufacturing – Demanding contamination-free fluid handling.

-

Power Generation Plants – Especially in nuclear and thermal sectors requiring radiation and pressure integrity.

-

Cryogenic & LNG Terminals – Where seal failure can compromise thermal insulation.

International Certifications & Standards

These valves are manufactured to meet the highest global standards:

-

API 602, BS 1873, and DIN EN ISO 15848-1 for design and emissions

-

TA-Luft Certified for fugitive emission performance

-

Fire-Safe Certification under API 607 / ISO 10497

A Technology Shift, Not Just a Trend

Experts highlight that bellow seal valves reduce long-term operational costs by eliminating the need for frequent repacking and maintenance. Their reliability under hazardous conditions also significantly lowers the risk of plant shutdowns and environmental damage.

Search Trends Reflect Growing Interest

With keywords like “external stem bellow seal globe valve manufacturer”, “zero emission gate valve”, and “ISO certified valve supplier in India” seeing increased search volume, the market clearly reflects a growing demand for emission-proof technologies.

About the Manufacturer

Freture Techno Pvt. Ltd., based in Mumbai, has emerged as a leading manufacturer of Bellow sealed globe and gate valves engineered for zero-emission performance. Offering custom-built solutions for complex flow control systems, the company is enabling industries to meet compliance goals without compromising operational efficiency.