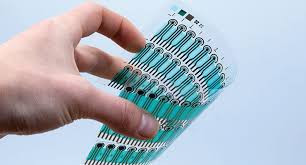

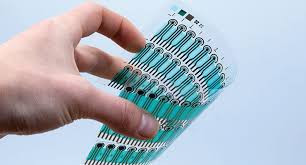

The printed sensors market is emerging as a transformative segment within the broader electronics and sensor industry. Leveraging advanced printing techniques like inkjet, gravure, and screen printing, these sensors offer advantages such as flexibility, cost efficiency, lightweight design, and adaptability for a wide range of applications. Despite their potential, the printed sensors market faces a number of critical hindrances that restrict its rapid growth and broader adoption. These challenges span technology, infrastructure, awareness, performance, and regulatory landscapes, making it essential to understand the barriers that must be overcome to unlock the market’s full potential.

Limited Performance in High-Precision Applications

One of the primary hindrances affecting the printed sensors market is the limitation in performance, particularly in high-precision or mission-critical applications. Printed sensors often lag behind their conventional counterparts in terms of sensitivity, resolution, and long-term stability. While they are suitable for applications where approximate data is sufficient—such as wearable fitness devices or basic environmental monitoring—they fall short in areas requiring high accuracy, such as medical diagnostics, aerospace monitoring, or automotive safety. This performance gap discourages industries that demand exact measurements from adopting printed alternatives.

Material and Ink Challenges

The reliability of printed sensors largely depends on the quality of functional inks and compatible substrates. However, these materials present challenges related to conductivity, thermal stability, mechanical strength, and longevity. Many conductive inks degrade when exposed to humidity, UV radiation, or mechanical stress, leading to compromised sensor functionality. The limited shelf-life and high cost of specialty inks also raise production costs, complicating large-scale manufacturing. Moreover, substrate-ink compatibility issues can lead to inconsistent printing results, which affects sensor performance and repeatability.

Lack of Standardization and Regulatory Frameworks

Another significant hindrance is the absence of universally accepted standards and regulatory frameworks for printed sensors. Unlike traditional sensors that benefit from decades of regulatory alignment, printed sensors operate in a relatively unregulated space. This lack of standardization complicates quality assurance, testing, and certification, particularly in industries with stringent compliance requirements like healthcare and transportation. Without clearly defined benchmarks, it becomes difficult for manufacturers to prove the reliability and safety of their products, slowing down market penetration and customer trust.

Scale-Up and Mass Production Constraints

Transitioning from prototype or small-batch production to high-volume manufacturing remains a substantial hurdle in the printed sensors market. Variability in printing processes, challenges in maintaining consistent print quality, and equipment limitations all hinder the scalability of printed sensor production. Each printing method has unique requirements for curing time, temperature control, and resolution, which complicates the production line and increases costs. These scale-up difficulties delay time-to-market and make it harder for manufacturers to meet growing demand at competitive prices.

Integration Difficulties with Existing Systems

For printed sensors to gain wider acceptance, they must integrate seamlessly into existing electronic systems. However, integration is often complex due to differences in form factor, voltage requirements, signal characteristics, and communication protocols. Printed sensors may require customized interfaces, amplifiers, or converters to work with conventional systems, which adds to the cost and engineering effort. This additional complexity can deter manufacturers and developers from incorporating printed sensors into their products, especially when off-the-shelf traditional sensors are readily available and compatible.

Environmental Durability and Operational Lifespan

In many applications, sensors must operate in harsh environments with exposure to moisture, dust, temperature fluctuations, and mechanical wear. Printed sensors generally lack the ruggedness needed for such conditions unless they are specially encapsulated or coated. These protective measures, however, can undermine the inherent advantages of printed sensors—such as thinness and flexibility—while also increasing costs. Until the environmental durability of printed sensors improves, their use will remain limited in industrial, automotive, and outdoor applications.

Insufficient Market Awareness and Technical Understanding

A less discussed yet impactful hindrance is the lack of awareness and technical understanding among potential end-users. Many companies and developers remain unfamiliar with the capabilities, benefits, and limitations of printed sensors. This lack of information leads to skepticism, underutilization, or incorrect implementation, which can further damage perceptions of their effectiveness. To overcome this, education, outreach, and real-world case studies are needed to demonstrate successful use cases and practical performance.

High Research and Development Costs

Although printed sensors promise low-cost solutions, the initial research and development phase is often expensive and time-consuming. Developing new sensor types, testing ink formulations, ensuring process compatibility, and building printing infrastructure all demand significant investment. For startups and smaller firms, these costs can be a major deterrent. Even for established companies, the long development cycle and uncertain ROI can limit enthusiasm for entering or expanding within the printed sensors market.

Conclusion

The printed sensors market holds substantial promise across a wide spectrum of industries, driven by its flexibility, affordability, and design adaptability. However, several hindrances continue to restrict its growth trajectory and widespread adoption. From technological limitations and material constraints to regulatory gaps and integration difficulties, overcoming these challenges is essential for the market to scale. Strategic collaborations, standardization efforts, targeted R&D, and end-user education will play key roles in removing these barriers and unlocking new opportunities in the future of printed sensing technologies.

Comments

0 comment