views

The Spain ceramic machinery market is undergoing a revolutionary transformation, with automation playing a pivotal role in reshaping the industry. As the demand for high-quality ceramics continues to rise, manufacturers are increasingly turning to automated solutions to streamline their operations, reduce costs, and enhance productivity.

Automation in ceramic production is not just a trend but a necessary step to stay competitive in a rapidly evolving market. In this article, we explore the impact of automation on Spain's ceramic machinery market, examining the latest trends, challenges, and how companies are adapting to this shift.

Understanding Spain's Ceramic Machinery Market

Spain is one of the leading ceramic producers in Europe, with the ceramics sector playing a crucial role in the country’s economy. The Spanish ceramic industry includes a wide range of products, from tiles and sanitary ware to tableware and industrial ceramics. The demand for ceramic products is increasing both domestically and internationally, which puts pressure on manufacturers to enhance production capabilities while maintaining high standards of quality.

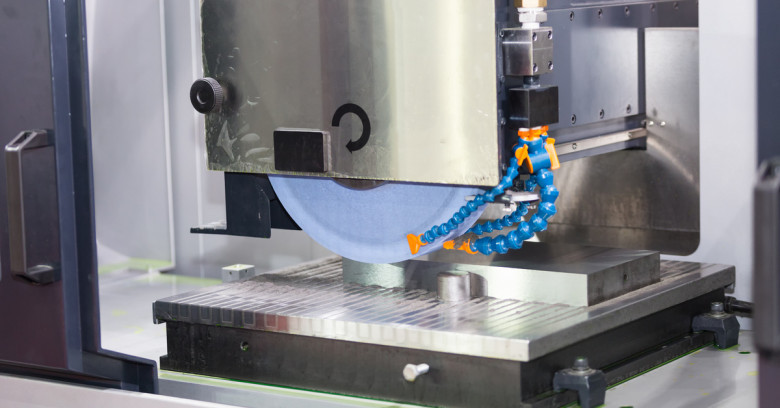

In response to this growing demand, the Spain ceramic machinery market has seen significant investments in technology, particularly automation. Automation in ceramic machinery involves the use of robotics, artificial intelligence (AI), machine learning, and advanced control systems to optimize production processes. These technological advancements enable manufacturers to increase efficiency, reduce human error, and improve the overall quality of their products.

The Rise of Automation in Ceramic Manufacturing

The integration of automation into ceramic manufacturing has been a game-changer for the industry in Spain. Several factors have contributed to this growing trend:

-

Rising Demand for High-Quality Ceramics: As consumer preferences shift toward high-quality, customized, and intricate ceramic products, manufacturers must adopt technologies that enable precise control over production processes. Automation allows for consistent quality control, ensuring that every piece of ceramic meets the highest standards.

-

Cost Reduction and Efficiency: Automation can significantly reduce operational costs by minimizing labor expenses, reducing production errors, and speeding up manufacturing processes. In an increasingly competitive market, Spanish ceramic manufacturers are investing in automation to stay ahead of competitors by offering faster turnaround times and more competitive pricing.

-

Sustainability Pressures: The growing emphasis on sustainability in manufacturing has prompted the ceramic industry to adopt cleaner, more energy-efficient technologies. Automation plays a key role in optimizing energy usage, reducing waste, and minimizing environmental impact, all of which are important for meeting both regulatory requirements and consumer expectations.

-

Global Competition: As global competition intensifies, Spanish ceramic manufacturers are under pressure to adopt advanced technologies that can help them remain competitive. Automation allows them to scale up production without sacrificing quality or increasing labor costs, helping them meet the demands of both domestic and international markets.

Key Trends in Automation in Spain’s Ceramic Machinery Market

-

Robotics in Production: One of the most prominent trends in the Spain ceramic machinery market is the increasing use of robotics. Robotic arms are now employed in various stages of production, including loading, unloading, glazing, and packaging. These robots offer several advantages, including precision, speed, and consistency. By automating repetitive tasks, manufacturers can increase throughput while reducing the risk of human error.

The integration of collaborative robots (cobots) is also on the rise. These robots work alongside human operators, assisting with tasks that require precision or lifting heavy loads. Cobots are particularly beneficial in the ceramic industry, where many tasks can be physically demanding or require intricate handling. -

AI and Machine Learning for Quality Control: Artificial intelligence (AI) and machine learning are playing an increasingly important role in automating quality control processes. In ceramic production, detecting defects and inconsistencies can be a time-consuming and costly task. AI-powered systems are now capable of analyzing production data in real-time, identifying defects, and making adjustments on the fly.

For example, AI-based vision systems can inspect ceramic tiles or sanitary ware for cracks, discoloration, or other imperfections. This automation not only speeds up the inspection process but also ensures that products meet the highest quality standards. As AI continues to advance, its role in quality control is expected to grow, enabling even more efficient and accurate detection of defects. -

Smart Factories and IoT Integration: The rise of "smart factories" is another significant trend in the Spain ceramic machinery market. These factories are equipped with Internet of Things (IoT) sensors that collect and transmit data about the production process in real-time. This data is then analyzed to optimize performance, detect potential issues, and predict maintenance needs.

IoT-enabled machines can communicate with each other, automatically adjusting settings to ensure optimal production. For example, in a ceramic kiln, IoT sensors can monitor temperature levels and adjust the firing process to prevent energy waste and improve the quality of the final product. The integration of IoT with automation enhances overall efficiency, reduces downtime, and helps manufacturers make data-driven decisions to improve operations.

-

3D Printing and Additive Manufacturing: 3D printing has emerged as a game-changing technology in the ceramic industry. It allows manufacturers to create intricate designs and prototypes without the need for traditional molds. While still in the early stages of adoption in the ceramic machinery market, 3D printing is gaining traction due to its potential for customization and cost savings.

In Spain, some companies are already using 3D printing for creating complex ceramic products and reducing lead times. This technology also allows for the production of small, specialized batches, enabling manufacturers to meet the growing demand for personalized and unique ceramic pieces.

-

Energy-Efficient Firing Systems: Firing is one of the most energy-intensive processes in ceramic production. To address growing environmental concerns and reduce operational costs, Spanish manufacturers are adopting energy-efficient firing systems that incorporate automation. These systems utilize advanced heat recovery technologies and automated temperature controls to optimize energy usage during the firing process.

Automated kilns are designed to ensure consistent firing conditions, reducing energy consumption and improving the overall efficiency of the production process. This not only helps manufacturers cut costs but also aligns with the increasing demand for sustainable production practices in the ceramic industry.

Challenges of Automation in Spain’s Ceramic Machinery Market

Despite the numerous advantages of automation in the ceramic machinery market, several challenges must be addressed for successful integration. These challenges include:

-

High Initial Investment: One of the primary barriers to automation adoption in the Spanish ceramic industry is the high initial cost of implementing automated systems. Robotic systems, AI-powered machines, and smart factory technologies require significant capital investment. For smaller manufacturers, the upfront costs of automation can be prohibitive, leading to concerns about return on investment.

However, as automation technology becomes more accessible and affordable, the cost of entry is expected to decrease. Many manufacturers are also benefiting from government incentives and subsidies that encourage the adoption of advanced technologies. -

Workforce Transition and Skill Gaps: The shift toward automation can create challenges related to workforce displacement. As machines take over repetitive tasks, certain jobs may be at risk of elimination. However, the rise of automation also creates new opportunities for skilled workers in areas such as robot programming, maintenance, and data analysis.

To address these challenges, companies must invest in training programs to upskill their workforce and ensure a smooth transition to automated systems. Collaboration between industry stakeholders, educational institutions, and government bodies is essential to address the potential skills gap in the automation sector. -

Integration with Existing Systems: Many ceramic manufacturers in Spain still rely on legacy systems that may not be compatible with newer automated technologies. Integrating automation into existing production lines can be a complex and time-consuming process, requiring significant technical expertise. Manufacturers must carefully plan their automation strategies to ensure seamless integration and avoid disruptions to production.

-

Cybersecurity Risks: As the ceramic industry becomes more connected through IoT and smart manufacturing technologies, the risk of cyberattacks increases. Protecting sensitive data and ensuring the security of automated systems is critical for manufacturers in Spain. Companies must implement robust cybersecurity measures to safeguard their operations and prevent potential data breaches or system failures.

Conclusion

The impact of automation on Spain’s ceramic machinery market is undeniable. As manufacturers increasingly embrace automation, they are able to streamline production processes, reduce costs, improve product quality, and stay competitive in a global marketplace. Trends such as robotics, AI-powered quality control, IoT integration, and energy-efficient firing systems are shaping the future of the industry, enabling companies to meet the growing demand for high-quality ceramics.

However, the path to full automation is not without its challenges. High initial investment costs, workforce transition issues, integration complexities, and cybersecurity risks must be addressed to ensure the successful implementation of automation in Spain’s ceramic machinery market. By overcoming these hurdles, Spanish manufacturers can position themselves for long-term success in an increasingly automated world.

Comments

0 comment