views

In these days’s rapid-paced industrial surroundings, efficiency is essential. One of the important ways to improve efficiency in a production or warehousing facility is by means of imposing computerized material positioning. Automated material positioning refers to the usage of generation and system to move, region, or align substances accurately inside a facility without guide exertions. This system reduces mistakes, saves time, and improves protection. If you want to know how to put into effect automated material positioning on your facility, this text will guide you through the key steps and concerns.

Understanding Automated Material Positioning

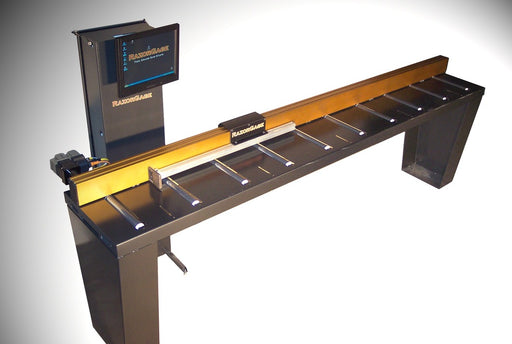

Before enforcing any systems, it’s essential to recognize what automated material positioning approaches. It involves the use of equipment which include conveyors, robotic palms, automatic guided cars (AGVs), or cranes controlled by computers or programmable logic controllers (PLCs). These systems are painted collectively to deal with substances, region them in exact locations, or put them together for the next step in the manufacturing or storage process.

This generation helps reduce the need for manual lifting, positioning, and transferring of materials that could often cause errors or injuries. With an automatic system, material positioning is extra correct and constant.

Benefits of Automated Material Positioning

Automating material positioning gives many benefits. First, it improves performance through speeding up the movement and site of materials. Systems can paint quicker and longer than humans without fatigue. Second, it enhances accuracy because systems may be programmed to locate substances in specific locations. This reduces the possibilities of mistakes and harm.

Third, automation improves safety by means of lowering the need for manual coping with heavy or risky materials. This lowers the threat of place of business accidents. Finally, automation can lessen exertion costs given that fewer workers are needed for material managing tasks, permitting your personnel to be aware of extra professional jobs.

Step 1: Assess Your Facility’s Needs

The first step to imposing automatic material positioning is to evaluate your facility’s unique desires. You ought to begin by searching at your current workflow and material handling processes. Identify bottlenecks or regions in which manual positioning slows down operations.

Consider the sorts of materials you take care of, their size, weight, and fragility. Some substances require very delicate coping with, whilst others are bulky or heavy. Understanding those info allows in choosing the right automation equipment.

Also, evaluate your facility’s format. Automated systems need space to operate, so recollect to have ground area, ceiling peak, and pathways for movement. Look at which materials input and go out the ability and where they may be stored or used.

Step 2: Set Clear Goals

After assessing your desires, set clean dreams for what you need to reap with automated material positioning. Do you want to reduce hard work costs? Increase velocity? Improve accuracy? Or all of these?

Having clear goals will manual the choice of generation and help degree the achievement of the implementation. For instance, if safety is your precedence, cognizance of automation that reduces human interaction with risky substances.

Step 3: Choose the Right Technology

There are several kinds of technologies used in computerized material positioning. Choosing the proper one relies upon your facility’s wishes, budget, and dreams.

-

Conveyor Systems: These are easy systems that pass substances along a set direction. They are ideal for transferring systems in an immediate line or along a fixed course.

-

Robotic Arms: Robots can pick out, pass, and region substances with excessive precision. They are flexible and can be programmed for complicated tasks.

-

Automated Guided Vehicles (AGVs): AGVs are mobile robots that transport substances round a facility. They follow pre-programmed routes and might circulate heavy loads.

-

Overhead Cranes and Gantries: These are used for heavy materials and can position objects in tough-to-reach regions.

-

Vision Systems and Sensors: These systems use cameras and sensors to guide equipment and make certain substances are placed effectively.

Sometimes, a combination of these technologies is pleasant. For example, conveyors can feed substances to a robot arm for specific placement.

Step 4: Plan the Integration

Once you’ve chosen the generation, planning how it will combine together with your present systems is crucial. Automated material positioning wishes to work smoothly with other procedures like inventory control, manufacturing strains, and best management.

Work with engineers and automation professionals to lay out the systems format. They will assist ensure the equipment suits the distance, connects properly to manipulate systems, and follows safety standards.

Integration also entails software. You may additionally want to put in or upgrade software to govern the automated system and acquire information on its performance.

Step 5: Train Your Team

Implementing automation doesn’t imply you don’t want people. In reality, your crew will want education to perform, display, and maintain the new systems.

Provide education classes on how the automatic systems works, protection techniques, and troubleshooting not unusual troubles. Skilled operators and technicians are crucial for retaining automation running easily.

Encourage your group to offer remarks for the duration of the implementation technique. They can assist in identifying issues and suggest improvements.

Step 6: Test the System

Before absolutely launching automatic material positioning, conduct thorough testing. Run the systems in a controlled environment to make sure it performs as anticipated.

Test distinct scenarios, which includes varying material sizes or weights, to peer how the system handles them. Check for accuracy, pace, and reliability.

This phase lets you make modifications and fix issues earlier than the system is going to stay.

Step 7: Implement Gradually

It’s frequently high-quality to enforce computerized material positioning gradually instead of . Start with a pilot location or an unmarried procedure.

This approach reduces risks and allows you to research and enhance before expanding automation to the whole facility.

Gradual implementation additionally gives your crew time to evolve to new workflows.

Step 8: Monitor and Improve

Once the system is going for walks, continuous tracking is important. Use software gear to music overall performance, including speed, accuracy, and downtime.

Regular preservation keeps equipment in proper circumstance and stops breakdowns.

Collect statistics and examine them to find regions for improvement. Automation isn't always a one-time setup however an ongoing method of optimization.

Challenges to Consider

While automated material positioning brings many advantages, it additionally comes with demanding situations. The preliminary fee of the system and installation can be excessive. Some centers might also want to modify their format, which can be steeply-priced and disruptive.

Technical issues together with software program bugs or system failure can reason downtime. You want professional personnel to control and restore the systems.

Safety is every other essential issue. Automated systems need to be mounted with right safeguards to protect workers.

Planning for these demanding situations and addressing them early will assist ensure a successful implementation.

Conclusion

Implementing automatic material positioning can remodel your facility through growing efficiency, improving accuracy, improving protection, and lowering labor expenses. While the process requires cautious planning, investment, and schooling, the benefits are well really worth the effort.

By assessing your needs, putting clear desires, selecting the right generation, and involving your crew, you can efficiently combine computerized material positioning into your operations. Continuous tracking and willingness to enhance will ensure your systems remain effective as your commercial enterprise grows.

Automation is not simply an alternative, however a necessary step closer to staying aggressive in these days’s business panorama. Embrace automatic material positioning and watch your facility become more productive, safer, and ready for the future.