views

Selecting the Proper Cooling Coil for Your HVAC Requirements: A Complete Guide

When it comes to HVAC systems, cooling coils may not always be in the spotlight—but they play a critical role in ensuring comfortable temperatures, efficient operation, and long-term system performance. Whether you’re designing a new system or upgrading an existing one, choosing the right cooling coil is essential. In this comprehensive guide, we’ll break down what cooling coils do, the different types available, and how to pick the right one for your specific needs.

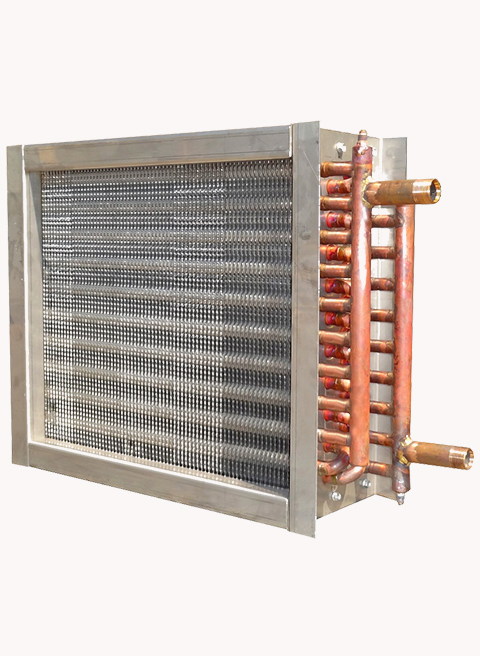

A cooling coil is a heat exchanger employed in HVAC systems to extract heat from air. It operates by circulating a cooling medium—typically chilled water or a refrigerant—through a matrix of tubes. As warm air flows over the coil, heat is transferred from the air to the fluid within the coil, reducing the air temperature before it's blown into the conditioned space.

Types of Cooling Coils

Knowing the types of cooling coils is the key to making a well-informed choice:

1. DX (Direct Expansion) Coils

Cooling Medium: Refrigerant

Common Application: Split ACs, packaged units

Benefits: Quicker cooling, space-saving

Ideal For: Small commercial buildings, residential systems

2. Chilled Water Coils

Cooling Medium: Chilled water from a central chiller

Common Application: Centralized HVAC systems

Benefits: Energy efficiency for large-scale applications

Ideal For: Commercial buildings, hospitals, data centers

3. Evaporator Coils

Sometimes used interchangeably with DX coils, but typically describes the indoor coil of a refrigeration or AC system.

Purpose: Picks up heat from the indoor air

Ideal For: Situations where small indoor units are required

Most Important Factors to Consider When Selecting a Cooling Coil

1. System Size and Load Requirements

Your coil has to equal the cooling load of the area. Oversizing results in short cycling and energy loss; undersizing results in improper cooling. Always conduct a load calculation prior to selection.

2. HVAC System Type

Are you dealing with a split system, VRF, chiller-based plant, or rooftop unit? The coil type has to be compatible with the system design.

3. Material Selection

Copper Tubes with Aluminum Fins: Suitable for most applications; provides adequate heat transfer and corrosion resistance.

All-Aluminum Coils: More resistant to corrosion, particularly in coastal or humid locations.

Epoxy-Coated Coils: Suitable for extreme chemical or marine conditions.

4. Coil Configuration

Observe:

Number of rows (influences cooling capacity)

Fin spacing (influences air resistance and heat transfer)

Coil face area (must match available space)

5. Maintenance Access

Provide sufficient space and access for coil cleaning and servicing. Dirty coils decrease efficiency and reduce equipment life.

6. Budget and Energy Efficiency

Initial cost is important, but it's also smart to consider long-term energy savings. More efficient coils may be more expensive to purchase but save a lot of money in operating costs.

Avoid These Common Mistakes

Neglecting Airflow Compatibility: Incompatible coil and fan airflow can result in inefficient operation.

Using Wrong Coil for Application: For instance, applying a DX coil in a chilled water system will not be effective.

Skipping Preventive Maintenance: Long-term coil performance requires regular cleaning and inspection.

Conclusion

Selecting the correct cooling coil isn't purely a technical choice—it's finding harmony between performance, efficiency, lifespan, and cost. Knowing your system requirements and the characteristics of various coils allows you to ensure maximum HVAC performance and comfort for years to come.

Whether you are an HVAC technician, a facilities manager, or simply someone attempting to learn about your system, investing the time to select the proper coil will make all the difference.

Comments

0 comment