views

JUGMUG’s Specialization: Precision Roll Forming for Complex Shapes

In the world of metal forming, precision is everything. Whether it’s for aerospace, automotive, construction, or renewable energy sectors, the demand for high-performance metal profiles is rising — and with it, the need for expertise in forming complex shapes. This is where JUGMUG Rollforming stands out. Specializing in precision roll forming for complex profiles, JUGMUG has carved a reputation as an industry leader, delivering solutions that combine innovation, engineering excellence, and manufacturing precision.

What is Precision Roll Forming?

Precision roll forming is a continuous bending process where a long strip of metal — typically coiled steel — is passed through consecutive sets of rolls. Each set incrementally shapes the metal until the desired cross-sectional profile is achieved.

What makes precision roll forming so powerful is its ability to produce complex, custom shapes with consistent dimensions over long production runs. Unlike press braking or extrusion, roll forming machine can handle very intricate designs, tight tolerances, and thin materials, all while maintaining material integrity and minimizing waste.

Tackling Complex Profiles

Many industries today require profiles that are anything but simple. We’re talking about intricate geometries, multi-plane bends, variable thicknesses, and designs that push the limits of traditional metal forming methods.

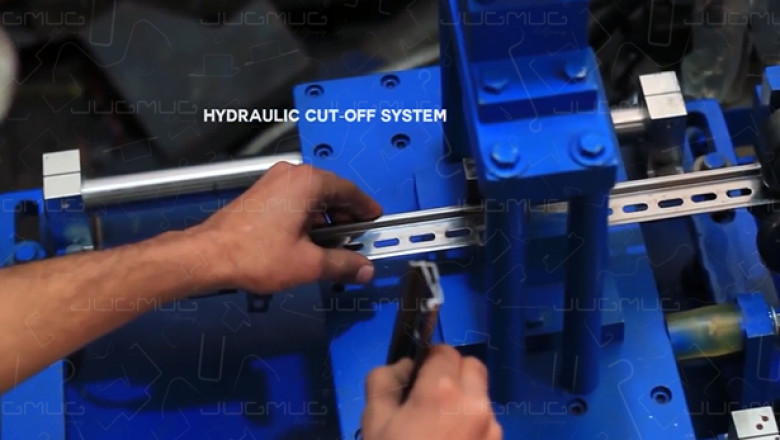

This is where JUGMUG’s specialization comes into play. The company has developed proprietary tooling, machine setups, and process controls that allow them to roll form extremely challenging profiles — ones that many others in the industry shy away from.

Whether it’s asymmetrical shapes, multi-part assemblies, or profiles requiring integrated features like perforations, slots, or embossing, JUGMUG’s engineering team takes on the challenge. They work closely with customers during the design phase to optimize the profile for roll forming, ensuring the final product meets exact performance, durability, and aesthetic requirements.

Why Choose Roll Forming Over Other Methods?

When it comes to forming complex roll forming profiles, several manufacturing processes are available, such as extrusion, stamping, or brake forming. However, roll forming offers distinct advantages:

-

Material Flexibility: Roll forming works with a wide range of metals, including high-strength steels, stainless steel, aluminum, brass, and copper.

-

Consistency: Thanks to the continuous nature of the process, profiles maintain tight dimensional tolerances over long production runs.

-

Cost Efficiency: Roll forming minimizes material waste and reduces labor costs compared to methods requiring multiple steps.

-

Customization: Complex cross-sections, integrated features, and even pre-painted or coated materials can be processed seamlessly.

-

Scalability: From small batches to large-scale production, roll forming can handle diverse production needs efficiently.

JUGMUG harnesses all these benefits and enhances them with its engineering know-how, advanced machinery, and commitment to quality.

Engineering Excellence at JUGMUG

At the heart of JUGMUG’s success is its engineering-driven approach. The company doesn’t just produce parts; it develops solutions.

From the moment a customer presents a profile requirement, JUGMUG’s technical team springs into action. They perform detailed design reviews, material analysis, and feasibility studies. Using CAD simulations, finite element analysis (FEA), and in-house prototyping, they ensure that the profile design is both manufacturable and optimized for performance.

JUGMUG also invests heavily in custom tooling — a critical factor when dealing with complex profiles. By designing and building precision roll dies in-house, the company maintains full control over the process, ensuring superior fit, finish, and functionality.

Quality Without Compromise

When forming complex shapes, there’s no room for error. A small deviation can compromise the integrity of the entire assembly. That’s why JUGMUG maintains strict quality control at every stage of production.

From raw material inspection to in-line monitoring and post-production testing, every part undergoes rigorous checks. JUGMUG’s facilities are equipped with advanced measurement tools, including laser scanners, optical comparators, and CMM machines, ensuring every profile meets or exceeds customer expectations.

Industries Served

JUGMUG’s precision roll forming expertise supports a wide range of industries, including:

-

Automotive: Lightweight, high-strength structural components.

-

Aerospace: Tight-tolerance profiles for airframe and interior applications.

-

Construction: Custom framing systems, curtain walls, and architectural features.

-

Energy: Solar panel frames, wind turbine components, and oil & gas structures.

-

Industrial Equipment: Conveyor systems, enclosures, and machine components.

No matter the industry, JUGMUG brings the same level of dedication, precision, and innovation to every project.

About JUGMUG Rollforming Company

JUGMUG Rollforming is a leading manufacturer specializing in precision roll forming of complex metal profiles. With decades of experience and a state-of-the-art facility, JUGMUG combines engineering expertise, advanced machinery, and a customer-first approach to deliver high-performance solutions across industries. Known for tackling challenging designs that many competitors avoid, JUGMUG has earned a reputation for innovation, quality, and reliability.

From initial concept to final delivery, JUGMUG partners with clients to bring even the most ambitious profiles to life — with precision, consistency, and efficiency.

Comments

0 comment