views

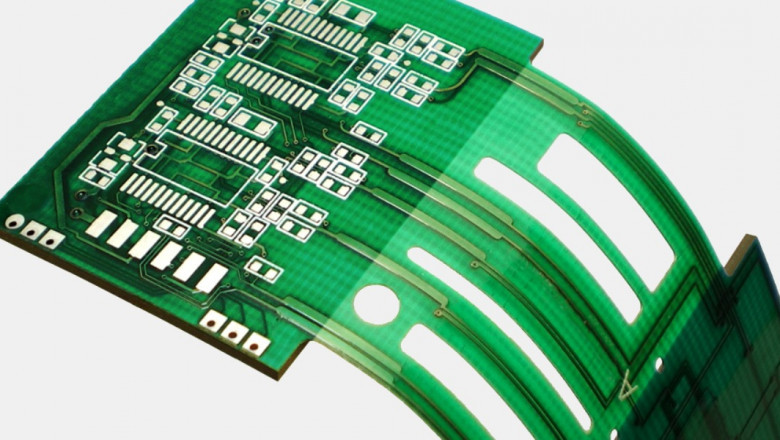

Understanding the Process of Flexible PCB Assembly: A Comprehensive Guide

Flexible printed circuit boards (PCBs) are essential for modern electronics due to their ability to bend and fit into compact spaces. Used in wearables, medical devices, and aerospace systems, their assembly requires a specialized process distinct from rigid PCBs. This article explores the key steps in flexible PCB assembly.

What Are Flexible PCBs?

Flexible PCBs, made from materials like polyimide or polyester films, offer bendable, foldable, and twistable designs, unlike rigid fiberglass-based PCBs. Their adaptability makes them ideal for mobile devices, wearables, automotive electronics, and medical devices, where compactness and durability are crucial.

Key Advantages of Flexible PCB Assembly

Space & Weight Savings – Thin and lightweight, ideal for compact devices in consumer electronics and aerospace.

Durability & Reliability – Withstands vibrations, shocks, and extreme temperatures, perfect for automotive and industrial use.

Design Flexibility – Can bend and fold to fit tight or irregular spaces, enabling innovative designs.

Improved Signal Integrity – Reduces connectors and interconnects, minimizing signal loss and electromagnetic interference.

Cost-Effective for Complex Designs – Though initially costly, they lower assembly costs by eliminating extra connectors, cables, and rigid boards.

Applications of Flexible PCB Assembly

Flexible PCBs are used in a wide range of industries, including:

Consumer Electronics: Smartphones, tablets, wearables, and laptops.

Medical Devices: Hearing aids, pacemakers, and imaging equipment.

Automotive: Sensors, LED lighting, and control systems.

Aerospace: Satellites, drones, and avionics systems.

Industrial Equipment: Robotics, sensors, and automation systems.

Flexible PCB Assembly Process

- Design & Prototyping – The circuit layout is created using specialized software, followed by prototyping to ensure functionality.

- Material Selection – Choosing the right flexible substrate (polyimide) and conductive materials (copper) is critical for durability.

- Printing & Etching – The circuit pattern is printed, and excess copper is etched away to form the required traces.

- Component Placement – Surface-mount technology (SMT) is used for precise component placement.

- Soldering & Inspection – Components are soldered via reflow or wave soldering, followed by AOI or X-ray inspection to detect defects.

- Testing & Quality Assurance – The final PCB undergoes rigorous testing to ensure reliability.

Challenges in Flexible PCB Assembly

- Handling & Assembly – More delicate than rigid PCBs, requiring specialized equipment.

- Higher Costs – Materials and processes can be more expensive than traditional PCB assembly.

- Design Complexity – Requires careful planning for bending radii, stress points, and material properties.

How Anzer Supports Flexible PCB Assembly

Anzer specializes in high-quality flexible PCB assembly, ensuring precision, reliability, and durability at every stage. Our team collaborates closely with clients to develop customized solutions for specific application needs.

- Custom Design Services – Tailored designs for flexibility, performance, and durability.

- High-Quality Materials – Premium polyimide substrates and conductive materials for long-lasting performance.

- Precision Assembly – Accurate component placement and flawless soldering, using both automated and manual processes.

- Rigorous Testing – Comprehensive functionality and reliability testing for real-world applications.

From consumer electronics to aerospace and medical devices, Anzer is your trusted partner for high-performance flexible PCBs.

Conclusion

Flexible PCB assembly requires careful design, fabrication, and testing to meet industry standards. By following each step with precision, manufacturers can produce reliable, high-performance flexible PCBs for cutting-edge applications. At Anzer, we are committed to delivering durable, functional, and high-quality flexible PCB assemblies for even the most demanding environments.

Looking for an expert PCB assembly partner? Anzer is here to bring your designs to life with precision and expertise.

Comments

0 comment