views

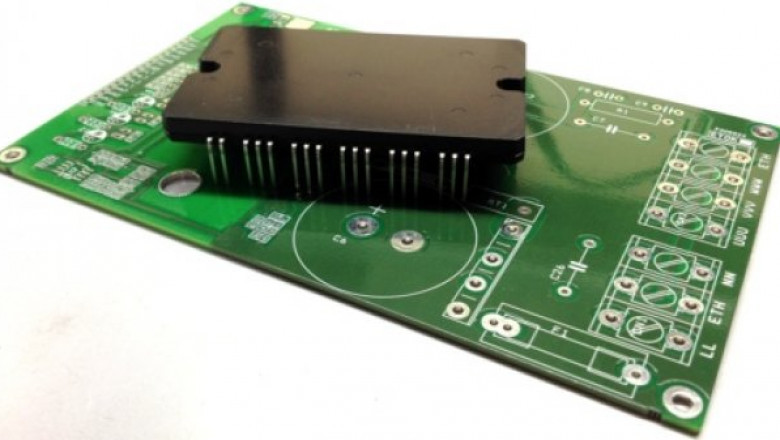

Intelligent power modules (IPMs) are discrete power semiconductor devices that integrate high- and low-voltage components of power electronics systems into a single package. An IPM typically includes power semiconductors like insulated-gate bipolar transistors (IGBTs) or metal-oxide-semiconductor field-effect transistors (MOSFETs), as well as their gate drive and protection circuits. This integration allows for compact and robust design while simplifying system assembly and maintenance.

Intelligent Power Module offer various advantages over discrete component designs. By incorporating gate drive and protection circuits, they eliminate the complexity of designing these control functions externally. Their hermetically sealed packaging provides protection against environmental stressors like moisture, dust, vibration, and thermal cycling. This makes IPMs well-suited for applications with harsh operating conditions. The module design also distributes switching and conduction losses uniformly, enhancing thermal performance.

Common Configurations and Applications

IPMs are available in different configurations suited for specific applications. For motor control, three-phase inverter modules are commonly used in applications like industrial motors, white goods, air conditioning equipment, and servo motors. Single-phase half-bridge and full-bridge modules are used in power supplies, solar inverters, speed controls, and welding equipment. Other specialized module types include half-bridge modules for motor drives, brake controllers and battery stacks.

IPM Applications in Automotive Electronics

The automotive industry has increasingly adopted IPMs for their stringent reliability requirements. In electric vehicles, IPMs allow for compact and efficient design of battery management systems, onboard chargers, and motor drives. In hybrid electric vehicles, they enable the downsizing of power converters while meeting thermal cycling and shock requirements.

Conventional automobiles also utilize IPMs extensively. Advanced safety features like electric power steering, adaptive cruise control, and active suspension systems rely on IPMs for reliable motor control. IPMs have also displaced discrete MOSFET designs in automotive gate drivers due to their intrinsic protection against faults. Body control modules, DC-DC converters for infotainment systems, and 48V micro-hybrid systems employ IPMs to minimize size and improve reliability.

IPM Considerations for Optimization

While IPMs simplify design and improve robustness, their bulky packaging increases device size and contributes significantly to overall system costs. Thermal optimization is also crucial to fully leverage their benefits. Proper heatsink design tailored to module characteristics helps maximize power density. New modules utilizing wide bandgap semiconductors like silicon carbide and gallium nitride claim higher switching frequencies and power densities.

Another consideration is the gate drive interface of IPMs. Modules with isolated gate drives provide protection against faults but increase complexity and cost. Modules with non-isolated drives require careful external gate resistor design but offer superior efficiency. The selection depends on specific application trade-offs between performance, robustness and cost.

The Future of IPMs in Emerging Technologies

Emerging technologies are expected to further propel IPM adoption. Electric aircraft present stringent size, weight and reliability constraints that motivate optimized IPM-based power electronics architectures. Offshore wind turbine generators stand to benefit from IPMs' compact yet rugged designs. Wireless charging standards are driving innovation in compact and customizable IPM modules for mobile device power supplies and consumer applications.

Additive manufacturing enables tailoring IPM packaging designs for thermal and mechanical optimizations. New wide bandgap materials could allow IPMs to leverage higher operating voltages for even more compact power stages. Designs integrating gallium-nitride-based transistors and silicon carbide diodes promise dramatic size and cost reductions. Developments in integrated magnetics and soft-switching topologies could allow multi-chip IPM modules for specific applications.

IPMs have emerged as crucial enablers of reliable and efficient power electronics across industrial, automotive and emerging technologies. Their standardized yet customizable packaging simplifies design while meeting stringent reliability demands. Continued advancements in materials, manufacturing and integration will expand IPM adoption into new applications. As systems increase in complexity, IPMs remain an effective means to optimize the performance, size and lifecycle costs of power converters. Their future potential is firmly tied to the ongoing transformation of industries with electrified and digitalized products.

Get this Report in Japanese Language- インテリジェント・パワー・モジュール

Get this Report in Korean Language- 지능형 전원 모듈

About Author-

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Known for her strong SEO background, she skillfully blends SEO strategies with insightful content. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

![[1 (888) 326-1024] How to Get in Touch with Expedia 24/7 Support Team: Phone, Email, and Chat Options](https://timessquarereporter.com/public/upload/media/posts/2025-06/01/1-888-326-1024-how-to-get-in-touch-with-expedia-24-7-support-team-phone-email-and-chat-options_1748757002-s.jpg)

Comments

0 comment