views

Introduction:

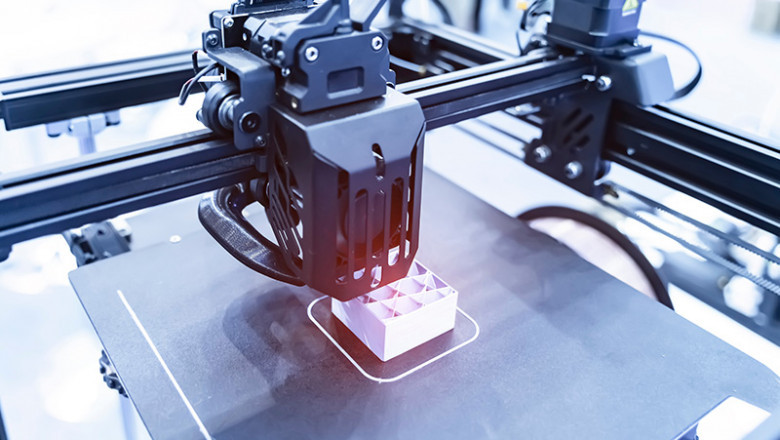

Taiwan Additive Manufacturing Market has seen remarkable advancements in recent years, with companies like Uniontech3D leading the charge in providing cutting-edge 3D printing solutions. Uniontech3D, a prominent player in the Taiwanese 3D printing market, is known for its innovative approach and commitment to developing high-performance printing technologies. The company has carved out a significant position in Taiwan’s rapidly growing AM sector by focusing on technological excellence, customer-driven solutions, and strategic market expansion. Uniontech3D’s contributions to the Taiwanese market are pivotal in shaping the future of additive manufacturing, particularly as industries demand more specialized, precise, and efficient 3D printing technologies.

Uniontech3D’s Role in Taiwan Additive Manufacturing Industry

Uniontech3D is recognized for its specialization in producing industrial-grade stereolithography (SLA) 3D printers. These printers are designed to meet the demanding requirements of industries such as automotive, aerospace, healthcare, consumer goods, and electronics. The company has made significant strides in enhancing the quality and efficiency of 3D printing, helping Taiwanese manufacturers improve their production processes and deliver better products to the market.

By offering both hardware and integrated software solutions, Uniontech3D provides a complete package that allows businesses to streamline their additive manufacturing processes. This comprehensive approach to 3D printing has enabled Uniontech3D to cater to a wide range of customers, from small businesses to large corporations, across various sectors.

Strategic Approach to Additive Manufacturing

Uniontech3D’s strategy for success in Taiwan’s AM market is built on a few key principles: innovation in technology, a strong focus on customer needs, fostering strategic partnerships, and continuous improvement in product offerings. These elements have allowed the company to stay ahead of its competitors and become a trusted name in the Taiwan additive manufacturing ecosystem.

Focus on Technological Innovation

One of Uniontech3D’s core strategies is its relentless focus on innovation. The company continually develops and refines its 3D printing technologies to provide solutions that meet the evolving demands of the market. Uniontech3D’s SLA printers are known for their exceptional print quality, precision, and speed, making them ideal for industries that require intricate designs and high-quality output. The company’s printers are equipped with advanced laser technology that ensures highly accurate prints, which is crucial for industries like aerospace and automotive, where part precision is vital for functionality and safety.

Moreover, Uniontech3D is committed to improving the overall efficiency of the 3D printing process. By developing faster print speeds, optimizing resin curing times, and reducing post-processing requirements, Uniontech3D helps businesses increase their productivity and reduce operational costs. This focus on efficiency has made Uniontech3D’s 3D printing solutions especially attractive to businesses in Taiwan that are looking to streamline their production processes.

Customization and Industry-Specific Solutions

Another key aspect of Uniontech3D’s strategy is its ability to provide customized solutions tailored to specific industries. The company understands that each sector has unique needs when it comes to additive manufacturing, and it adapts its solutions to cater to these demands. For instance, Uniontech3D’s SLA printers are widely used in the automotive industry to produce high-precision prototypes, tooling components, and end-use parts. In healthcare, the company’s technology is used to create custom dental implants, hearing aids, and surgical models that require a high degree of accuracy and material compatibility.

Uniontech3D’s ability to deliver industry-specific solutions has made it a go-to provider for many businesses in Taiwan. Its customized approach not only helps customers meet their operational goals but also enables them to push the boundaries of product design and innovation. By developing specialized materials and optimizing their printing processes, Uniontech3D has helped customers across various industries achieve their goals faster and more cost-effectively.

Expanding Partnerships and Collaboration

Uniontech3D has also placed significant emphasis on building strategic partnerships and collaborating with key players in the industry. Through its partnerships with material suppliers, software developers, and other technology companies, Uniontech3D has been able to enhance its product offerings and remain at the cutting edge of the 3D printing sector. These collaborations allow the company to access new materials, refine its printing techniques, and introduce new functionalities to its machines.

Additionally, Uniontech3D has teamed up with educational institutions, research organizations, and industry leaders to foster innovation and stay ahead of emerging trends in additive manufacturing. These partnerships help the company stay abreast of technological advancements and market shifts, ensuring that its solutions remain relevant and competitive in the dynamic AM landscape.

Commitment to Sustainability

As sustainability becomes an increasingly important consideration for manufacturers around the world, Uniontech3D has made it a priority to incorporate environmentally friendly practices into its operations. The company has worked to develop 3D printing solutions that minimize material waste, reduce energy consumption, and utilize sustainable materials. By improving the sustainability of its technology, Uniontech3D not only helps its customers achieve their environmental goals but also aligns with Taiwan’s growing emphasis on sustainable manufacturing practices.

In addition, Uniontech3D’s commitment to sustainability extends beyond its own operations to include its products. The company has developed resins that are more environmentally friendly while maintaining the high performance and precision required by industries such as aerospace, automotive, and healthcare. By offering these sustainable options, Uniontech3D helps businesses in Taiwan reduce their environmental footprint without sacrificing quality.

Emerging Innovations from Uniontech3D

Uniontech3D is continuously innovating to improve its product offerings and stay ahead of the competition in Taiwan’s additive manufacturing market. Several emerging innovations from Uniontech3D are helping drive the growth of the AM sector, both locally and globally.

Advanced SLA Technology

Uniontech3D’s flagship product line consists of SLA 3D printers that utilize high-powered lasers to cure photopolymer resins into solid parts. The company has made significant advancements in this technology, increasing the resolution and speed of its machines. These advancements have expanded the range of applications for SLA 3D printing, particularly in industries where precision and detail are paramount. For instance, Uniontech3D’s printers are used to create complex geometries in aerospace components, intricate jewelry designs, and detailed dental models.

One of the company’s most notable innovations is the development of low-shrinkage resins that offer better material properties and allow for the production of larger, more accurate parts. These resins help reduce the need for post-processing, making the entire 3D printing process faster and more efficient.

Automation and Software Integration

Uniontech3D has also made strides in integrating automation into its 3D printing systems. The company’s machines are equipped with advanced software that allows for greater control over the printing process, optimizing print paths and material usage. Automation in post-processing tasks, such as cleaning and curing, has significantly improved the overall workflow, reducing the need for manual labor and increasing operational efficiency.

Moreover, Uniontech3D’s software integration capabilities allow for seamless collaboration between designers, engineers, and manufacturers. This ensures that the final product meets the required specifications and minimizes the risk of errors during the printing process.

Expanding Material Options

As additive manufacturing technologies continue to evolve, Uniontech3D is constantly working to expand its material offerings. The company has developed a range of advanced resins designed to meet the specific needs of various industries, including high-temperature resins for aerospace applications and biocompatible resins for medical devices.

These material innovations are driving the growth of additive manufacturing in Taiwan, particularly in industries that require specialized materials for high-performance applications. By expanding its material capabilities, Uniontech3D enables companies in Taiwan to create a broader range of functional parts and prototypes, further establishing the company as a leader in the AM market.

Uniontech3D’s Impact on Taiwan’s Additive Manufacturing Market

Uniontech3D has had a profound impact on the Taiwanese additive manufacturing market, driving technological advancements and supporting the growth of key industries. The company’s commitment to providing high-quality, precise, and customizable 3D printing solutions has made it a preferred choice for many manufacturers in Taiwan. Through its innovation in SLA printing technology, material development, and automation, Uniontech3D has positioned itself as a pivotal player in the expansion of Taiwan’s AM sector.

As the demand for additive manufacturing continues to rise, Uniontech3D’s focus on technological innovation, industry-specific solutions, and sustainability will play an essential role in shaping the future of Taiwan’s additive manufacturing market. The company’s contributions will not only drive Taiwan’s AM industry forward but also have a lasting impact on the global 3D printing landscape.

Conclusion

Uniontech3D is a standout player in Taiwan’s additive manufacturing market, providing advanced 3D printing technologies that cater to a wide range of industries. Through its commitment to innovation, customization, and sustainability, Uniontech3D has positioned itself as a leader in the AM sector. The company’s ongoing development of cutting-edge technologies, from advanced SLA printers to expanded material options, ensures that it remains at the forefront of the industry. As the additive manufacturing market continues to grow, Uniontech3D’s role in shaping its future is set to become even more significant.

Comments

0 comment