views

Introduction

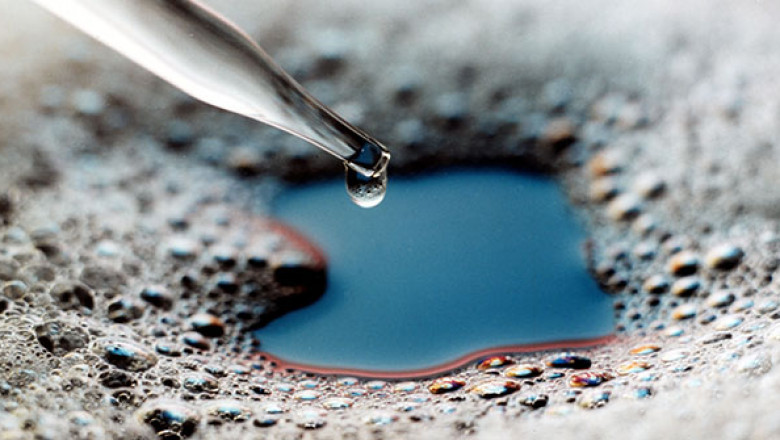

Anti-Foaming Agents Market, also known as defoamers, play a crucial yet often overlooked role in the food and beverage industry. These agents help prevent foam formation, which can disrupt manufacturing processes, reduce efficiency, and compromise product quality. As food and beverage production scales up, the demand for high-performance, food-grade, and allergen-free defoamers is rising. This article explores the significance of anti-foaming agents, their impact on various industries, and the growing market for safer and more effective solutions.

Preventing Foam Formation in Dairy, Brewery, and Sugar Industries

Foam formation is a common challenge in food processing industries, particularly in dairy, brewery, and sugar production. Excessive foam can lead to inefficiencies, contamination risks, and increased processing times.

- Dairy Industry: During milk pasteurization and cheese production, foaming can interfere with heat transfer, leading to inconsistent product quality. Anti-foaming agents ensure smooth processing and maintain product integrity.

- Brewery Industry: In beer brewing, foam generation during fermentation can cause overflow and reduce yield. Defoamers help maintain optimal fermentation conditions by controlling excessive frothing.

- Sugar Industry: Sugar crystallization and refining involve processes where foam can hinder evaporation and filtration. Anti-foaming agents improve efficiency by reducing surface tension and accelerating sugar processing.

Impact on Beverage Carbonation, Fermentation, and Frying Processes

Anti-foaming agents influence various aspects of beverage and food processing beyond just foam prevention. Their role is integral to maintaining consistency and ensuring product safety.

- Beverage Carbonation: Soft drinks and sparkling beverages rely on controlled carbonation levels. Foam formation during bottling can lead to product loss and inconsistent carbonation. Defoamers help minimize such losses and enhance production efficiency.

- Fermentation Processes: Fermented foods and beverages, including kombucha and yogurt, undergo microbial activity that can produce unwanted foam. Anti-foaming agents ensure controlled fermentation and maintain product stability.

- Frying and Cooking Oils: In snack and fast-food production, excessive foaming in frying oils can lead to uneven cooking and reduced oil lifespan. Defoamers enhance oil efficiency, maintaining consistent frying quality and reducing waste.

Rising Demand for Food-Grade, Allergen-Free Defoamers

As consumer awareness of food safety grows, the demand for food-grade and allergen-free anti-foaming agents is increasing. The industry is witnessing a shift toward natural and organic alternatives that meet regulatory standards and cater to health-conscious consumers.

- Food Safety Regulations: Stringent regulations by food safety authorities such as the FDA and EFSA require anti-foaming agents to be non-toxic, heat-stable, and residue-free.

- Plant-Based and Organic Alternatives: Manufacturers are developing natural defoamers derived from plant-based oils and waxes to align with clean-label trends.

- Allergen-Free Solutions: With rising cases of food allergies, food processors are opting for allergen-free anti-foaming agents to avoid cross-contamination and improve consumer confidence.

Conclusion

Anti-foaming agents play an indispensable role in food and beverage processing, ensuring efficiency, quality, and product consistency. Industries such as dairy, brewing, and sugar production rely heavily on defoamers to prevent foam-related inefficiencies. Moreover, with the increasing demand for food-grade and allergen-free solutions, the market is evolving toward safer and more sustainable alternatives. As innovation continues, the adoption of natural and compliant anti-foaming agents is set to rise, shaping the future of food processing technologies.

Comments

0 comment