views

Introduction

The Indonesia ATLS Market is undergoing a significant transformation, driven by the integration of Artificial Intelligence (AI) and the Internet of Things (IoT) into Automated Truck/Trailer Loading Systems (ATLS). These technological advancements are enhancing operational efficiency, reducing costs, and improving safety across various industries, including manufacturing, automotive, and FMCG. This article explores how AI and IoT are revolutionizing Indonesia's ATLS market, highlighting the benefits of predictive maintenance, real-time data analytics, and smart logistics.

Understanding ATLS and Its Components

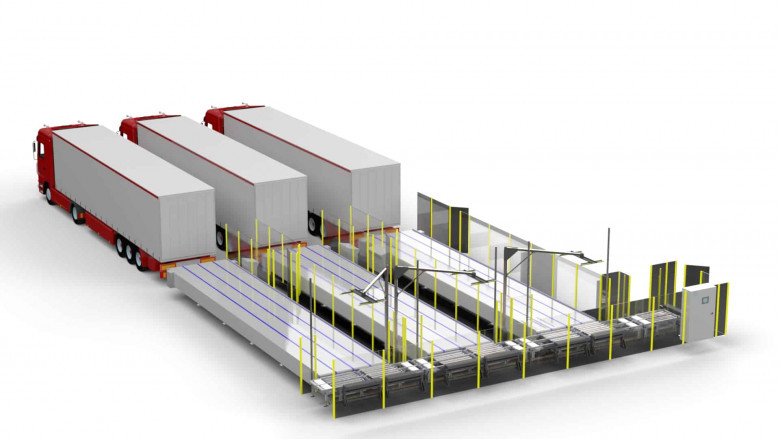

An Automated Truck/Trailer Loading System (ATLS) is a technology-driven solution designed to automate the loading and unloading processes of trucks and trailers. Typically, an ATLS comprises:

- Conveyor Systems: These include chain, slat, belt, and roller conveyors that transport goods to and from loading docks.

- Loading Docks: Specialized areas where goods are transferred between conveyors and vehicles.

- Control Systems: Software that manages the loading/unloading operations, ensuring efficiency and safety.

The primary goal of ATLS is to streamline logistics operations by automating manual tasks, thereby improving productivity and reducing human error.

The Role of AI and IoT in Enhancing ATLS

- Predictive Maintenance

Predictive maintenance utilizes IoT sensors and AI algorithms to monitor the health of equipment in real-time. By analyzing data such as vibration, temperature, and pressure, these systems can predict potential failures before they occur. For instance, a logistics company implemented a predictive maintenance system that reduced unplanned downtime by 50% and significantly lowered maintenance costs.

- Real-Time Data Analytics

IoT-enabled sensors collect vast amounts of data during loading and unloading operations. AI processes this data to provide actionable insights, enabling logistics managers to make informed decisions. This real-time analytics helps in optimizing loading patterns, reducing wait times, and enhancing overall efficiency.

- Smart Logistics Integration

Integrating ATLS with smart logistics platforms allows for seamless communication between various components of the supply chain. IoT devices track goods throughout their journey, providing visibility and ensuring timely deliveries. AI analyzes this data to optimize routes and schedules, further improving efficiency and customer satisfaction.

Case Studies: AI and IoT in Action

- Automotive Industry in Karawang: In Karawang, a region known for its automotive manufacturing, companies have adopted IoT and AI technologies to optimize machine maintenance. A study found that these technologies reduced downtime and enhanced operational efficiency by 65%.

- General Electric (GE): GE implemented predictive maintenance across its manufacturing facilities, including jet engine production lines. By utilizing sensors and IoT technology, GE achieved a 10% reduction in maintenance costs and improved overall equipment effectiveness.

- Siemens: Siemens applied predictive maintenance in its gas turbine manufacturing process by analyzing vibration and temperature data from turbines. This proactive strategy not only enhanced safety but also extended the lifespan of their turbines, resulting in significant cost savings.

Market Outlook and Future Trends

- Increased Adoption of Automation: Businesses are increasingly integrating ATLS with existing automation setups like conveyor systems and robotic material handling to enhance operational efficiency.

- Rising Labor Costs: The escalating labor expenses are prompting companies to adopt ATLS to reduce reliance on human labor and ensure consistent performance.

- Technological Advancements: The integration of AI and IoT into ATLS is providing valuable data insights, enabling informed decision-making and process optimization.

Challenges and Considerations

Despite the benefits, several challenges hinder the widespread adoption of ATLS in Indonesia:

- High Initial Investment: The substantial upfront costs associated with ATLS deployment, including technology procurement and infrastructure investments, can be a barrier for small and medium-sized enterprises (SMEs).

- Integration Complexities: Integrating ATLS with existing logistics and warehouse management systems requires careful planning and skilled personnel.

- Training and Skill Development: The need for specialized training to operate and maintain advanced ATLS systems is essential to ensure effective implementation.

Conclusion

The integration of AI and IoT into Automated Truck/Trailer Loading Systems is transforming Indonesia's logistics landscape. By enabling predictive maintenance, real-time data analytics, and smart logistics integration, these technologies are enhancing operational efficiency and reducing costs. While challenges such as high initial investment and integration complexities exist, the long-term benefits make ATLS a valuable investment for companies aiming to stay competitive in the evolving logistics sector. As the market continues to grow, embracing these technological advancements will be crucial for businesses seeking to optimize their logistics operations and achieve sustainable growth.

Comments

0 comment