views

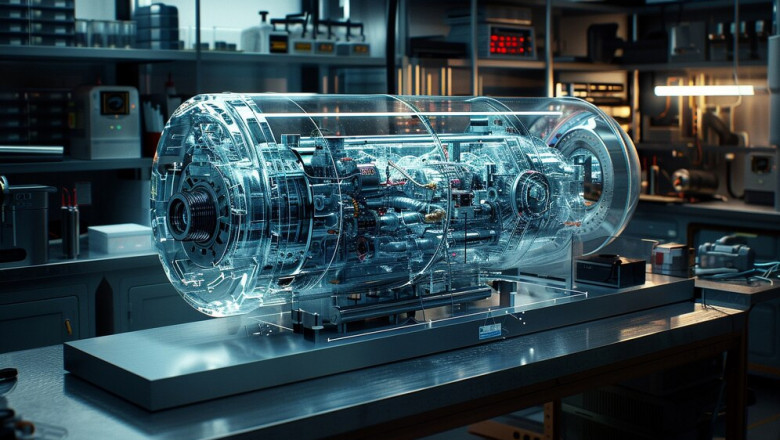

The Gas Jet Compressor Market has become an essential component in various industries, including oil and gas, chemical, and HVAC systems, due to its ability to efficiently move gases without the need for moving mechanical parts. As the market grows and diversifies, it faces several challenges and pain points that need to be addressed to maintain its relevance and drive innovation. This article reviews these challenges and emerging trends, offering strategic insights into the future of the gas jet compressor market.

Challenges in the Gas Jet Compressor Market

One of the primary challenges the gas jet compressor market faces is technological limitations. Traditional gas jet compressors, while effective, have limitations in terms of energy efficiency and scalability. These compressors rely on high-pressure gas to move a secondary gas, which can result in high energy consumption and operational costs. As industries push for more sustainable solutions, manufacturers are being forced to innovate and develop compressors with higher efficiency and reduced environmental impact.

Another significant pain point is the complexity of system integration. Gas jet compressors are often part of complex industrial systems that require seamless integration with other machinery, control systems, and safety mechanisms. This integration can be challenging, particularly in retrofitting older systems with newer compressor technologies. Ensuring compatibility and smooth operation between different components while maintaining system reliability is a persistent challenge in the industry.

Additionally, maintenance and reliability concerns continue to pose a problem for gas jet compressors. These systems, though designed for durability, can suffer from wear and tear over time, leading to breakdowns or inefficiencies. The absence of moving parts does not eliminate the need for regular maintenance, particularly in high-pressure environments. Failure to address maintenance needs can result in operational downtimes, which can be costly for industries relying on continuous processes.

Emerging Trends in the Gas Jet Compressor Market

Despite these challenges, there are several emerging trends in the market that could shape its future. One key trend is the increasing adoption of digitalization and automation in compressor operations. With the rise of Industry 4.0, gas jet compressors are becoming smarter, with integrated sensors and IoT technology that allow for real-time monitoring of performance. These advancements enable predictive maintenance, helping companies avoid costly breakdowns by addressing issues before they escalate.

Another trend is the growing focus on energy efficiency and sustainability. With rising energy costs and a global push for greener solutions, industries are demanding compressors that consume less energy while offering the same, if not better, performance. Manufacturers are responding by designing more energy-efficient gas jet compressors, utilizing advanced materials, and adopting environmentally friendly refrigerants. This trend aligns with the overall movement towards more sustainable industrial practices.

Customization and modular design are also becoming increasingly popular. Industries such as oil and gas, which operate in diverse environmental conditions, require compressors that can be tailored to specific needs. Modular compressor systems, which allow for easy upgrades and custom configurations, are gaining traction as they offer both flexibility and cost efficiency. This adaptability is crucial as companies look for ways to optimize operations while minimizing downtime.

Strategic Insights for Industry Players

To navigate these challenges and capitalize on emerging trends, companies in the gas jet compressor market should focus on several key strategies. First, investment in R&D is essential to developing more efficient, sustainable, and reliable compressor technologies. By focusing on innovation, manufacturers can differentiate themselves from competitors and offer solutions that meet the evolving demands of the market.

Second, companies should embrace digital transformation by incorporating IoT-enabled devices, AI, and machine learning into their compressor systems. These technologies offer significant potential for improving system performance, enhancing reliability, and reducing maintenance costs.

Lastly, collaboration with end-users is critical to understanding the specific needs of various industries. By working closely with clients, manufacturers can design tailored solutions that address the unique challenges of each sector, whether it's in terms of performance, energy efficiency, or system integration.

Conclusion

The gas jet compressor market continues to evolve as industries seek more efficient, sustainable, and customizable solutions. While challenges such as technological limitations, system integration, and maintenance concerns persist, emerging trends like digitalization, energy efficiency, and modular designs provide valuable opportunities for innovation. By embracing these trends and focusing on strategic advancements, industry players can position themselves for success in an increasingly competitive market.

Comments

0 comment