86

views

views

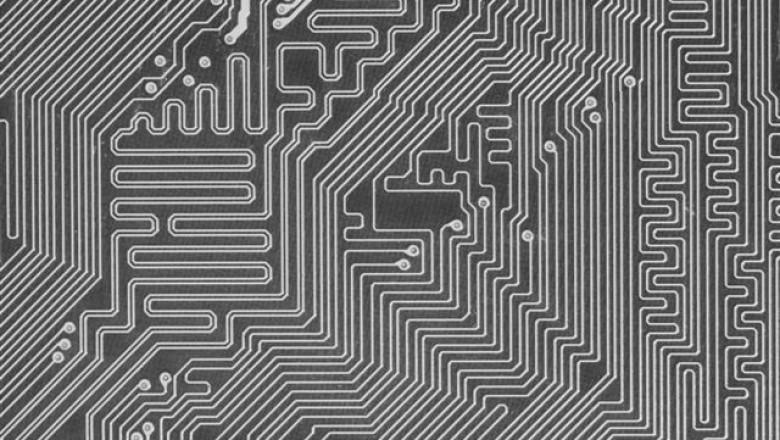

The conductive inks market is expanding due to increased demand in sectors like printed electronics, IoT, and automotive. Innovations in sustainable and flexible inks are driving growth, along with advancements in printing technologies.

The conductive inks market is experiencing rapid expansion, driven by the growing demand for printed electronics, advancements in material science, and rising applications in automotive, healthcare, and consumer electronics. These inks enable the development of flexible, lightweight, and cost-effective electronic components, making them a crucial element in emerging technologies. This market is influenced by several dynamic factors, including technological advancements, regulatory policies, industry collaborations, and evolving consumer demands. Below are the key market dynamics shaping the conductive inks market.

Market Drivers

- Expanding Demand for Printed Electronics – Increasing adoption of printed circuit boards (PCBs), antennas, and RFID tags is propelling market growth.

- Rising Popularity of Wearable Devices – Smartwatches, fitness bands, and medical monitoring devices require flexible and durable conductive materials.

- Growth in Smart Packaging Solutions – Integration of printed sensors and RFID technologies in packaging enhances traceability and security.

- Increase in IoT Applications – The demand for sensors and antennas in IoT-enabled devices is boosting the adoption of conductive inks.

- Automotive Industry Adoption – Electric vehicles (EVs) and advanced driver-assistance systems (ADAS) require conductive inks for flexible circuits.

- Advancements in Printing Technologies – Inkjet and screen printing innovations are enabling cost-effective mass production of electronic components.

- Development of Alternative Conductive Materials – Copper, carbon, and graphene-based inks are gaining traction as cost-effective alternatives to silver inks.

- Rising Investment in R&D – Companies and research institutes are actively developing more efficient, durable, and sustainable conductive ink formulations.

Market Challenges

- High Cost of Silver-Based Conductive Inks – Silver remains the most widely used material, but its high price impacts cost-effectiveness.

- Material Limitations and Performance Issues – Alternative materials like copper and graphene need further development to match silver's conductivity.

- Durability Concerns in Harsh Environments – Conductive inks must withstand mechanical stress, high temperatures, and moisture without performance degradation.

- Complex Manufacturing Processes – Production of high-quality conductive inks requires precise formulation and advanced printing techniques.

- Regulatory and Environmental Compliance – Stringent regulations regarding the use of heavy metals and chemical formulations impact product development.

- Limited Awareness Among End-Users – Many industries are still unaware of the benefits and applications of conductive inks in their production processes.

- Supply Chain Disruptions – Fluctuations in raw material availability and geopolitical tensions can impact production and pricing.

Market Trends

- Growing Adoption of Sustainable and Eco-Friendly Conductive Inks – Manufacturers are focusing on reducing environmental impact by developing biodegradable and solvent-free inks.

- Development of Stretchable and Flexible Conductive Inks – These innovations cater to applications in flexible electronics, textiles, and medical devices.

- Integration of Conductive Inks in 3D Printing – Conductive inks are increasingly being used to print three-dimensional electronic components.

- Miniaturization of Electronic Components – The need for smaller and more efficient devices is driving the demand for high-performance conductive inks.

- Emergence of Hybrid Conductive Inks – Combination of multiple conductive materials to enhance conductivity, durability, and flexibility.

- Asia-Pacific Leading Market Growth – Countries like China, Japan, and South Korea are investing heavily in printed electronics and conductive ink technologies.

- Partnerships and Collaborations in the Industry – Companies are forming strategic alliances to enhance product innovation and expand market presence.

- Rise in Printed Energy Storage Devices – Conductive inks are being used in the development of printed batteries and supercapacitors for energy storage applications.

Market Opportunities

- Expansion into Emerging Industries – The integration of conductive inks in aerospace, defense, and industrial automation presents significant opportunities.

- Innovation in Conductive Ink Formulations – Development of low-cost, highly conductive, and printable inks can attract new applications.

- Growth in Smart Textiles and E-Textiles – Conductive inks are increasingly being used to create interactive clothing with embedded electronic functions.

- Increased Government Funding for Research – Governments worldwide are supporting research into advanced electronics and conductive material innovations.

- Potential in Biocompatible Conductive Inks – The medical industry is exploring conductive inks for applications in biosensors and implantable devices.

- Advancement in Transparent Conductive Inks – These inks are used in touchscreens, OLED displays, and solar panels for enhanced functionality.

- Scaling Up Mass Production Technologies – Investment in large-scale production facilities can help reduce costs and increase market penetration.

- Integration with Artificial Intelligence and Machine Learning – AI-driven design and manufacturing can optimize conductive ink formulations for better performance.

Competitive Landscape

- Key Market Players – Major companies include Henkel, DuPont, NovaCentrix, Sun Chemical, and Creative Materials.

- Focus on Product Differentiation – Companies are developing specialty inks tailored for specific applications such as printed sensors and flexible circuits.

- Mergers and Acquisitions – Industry leaders are acquiring startups and smaller firms to expand their product portfolios.

- Investment in Smart Manufacturing Technologies – Automation and AI-driven processes are improving production efficiency and product quality.

- Expansion Strategies of Key Players – Companies are entering new geographic markets and expanding production capacity to meet growing demand.

Future Outlook

- Projected Market Growth – The conductive inks market is expected to witness robust expansion driven by advancements in material science and increasing demand for flexible electronics.

- Sustainability Will Shape Market Development – Eco-friendly formulations and recyclable conductive inks will become a major focus for manufacturers.

- Technological Innovations Will Drive Market Evolution – Continued R&D in nanomaterials and hybrid inks will lead to more efficient and versatile products.

- Increasing Adoption in Consumer Electronics – Demand for conductive inks will rise as smart devices, foldable displays, and connected gadgets become mainstream.

- Market Expansion into New Regions – Developing countries in Asia, Latin America, and Africa will contribute significantly to market growth.

- Industry 4.0 and Smart Manufacturing Will Boost Adoption – Conductive inks will play a crucial role in the advancement of automation and next-generation manufacturing.

Comments

0 comment