views

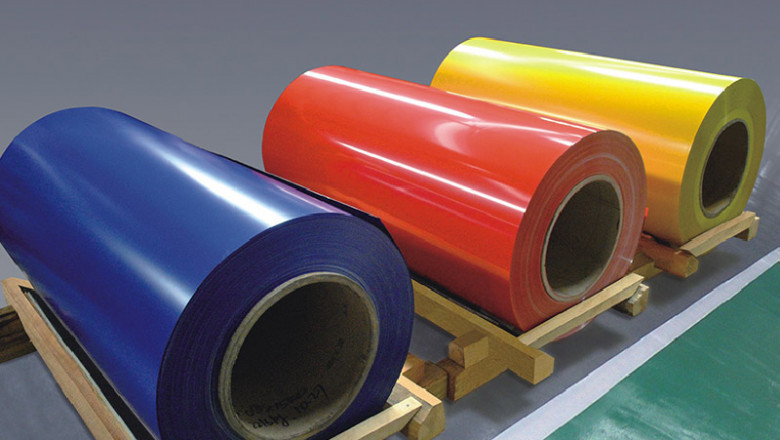

The coil coatings market plays a pivotal role in the manufacturing of pre-painted metal sheets, which are widely used across various industries. Coil coating is the process in which metal sheets, primarily steel or aluminum, are coated with a thin layer of protective and decorative paint. This process is usually performed in a continuous operation and provides the metal with improved corrosion resistance, UV protection, and aesthetic appeal. The demand for coil coatings is expected to grow significantly, driven by expanding industries like construction, automotive, home appliances, and packaging.

Market Overview and Key Drivers

The global coil coatings market is primarily driven by factors such as rapid urbanization, industrial growth, increased infrastructure development, and the rising demand for aesthetic, durable materials. In the construction industry, coil-coated metals are highly favored due to their long lifespan, resistance to weathering, and ability to be customized with a variety of finishes. These coatings also offer cost-effective solutions compared to other surface protection options. Similarly, in the automotive sector, coil coatings are used for exterior parts that need to be lightweight, durable, and resistant to the elements.

The growing demand for energy-efficient and sustainable buildings further fuels the growth of the coil coatings market. Many governments are mandating the use of more sustainable materials in construction, leading to the adoption of coil-coated metals that are highly energy-efficient. Additionally, eco-friendly coil coatings, such as water-based coatings, are gaining popularity due to the rising awareness regarding environmental sustainability.

Key Applications

-

Construction: The construction industry is the largest end-use sector for coil coatings. Coil-coated metals are used in roofing, facades, cladding, and interior panels. Their high durability and ability to withstand extreme weather conditions make them ideal for these applications. Furthermore, they can be made with a variety of colors and finishes, including matte, gloss, and metallic, which are highly preferred in architectural designs.

-

Automotive: Coil coatings are increasingly used in the automotive sector for vehicle body parts, including bumpers, grilles, and trim. These coatings provide resistance against scratches, UV radiation, and corrosion, contributing to the longevity and appearance of vehicles. As the demand for lightweight and fuel-efficient vehicles rises, coil-coated aluminum is gaining popularity for automotive applications.

-

Home Appliances: In the home appliance industry, coil coatings are applied to products like refrigerators, ovens, washing machines, and air conditioners. These coatings protect appliances from rust, corrosion, and wear, helping to extend their lifespan. With the increasing demand for durable and energy-efficient appliances, the market for coil coatings in this sector is expected to grow.

-

Packaging: Coil-coated metals are used in the packaging industry, especially for products requiring food-safe containers or packaging. The coatings ensure that the metals are resistant to corrosion, ensuring that packaged products remain safe and unspoiled. In addition, the wide array of colors available with coil coatings enhances the visual appeal of packaging, contributing to brand differentiation.

Technological Developments

Technological innovations are continuously transforming the coil coatings market. The development of advanced formulations that are more environmentally friendly and efficient is one of the key trends. Water-based coil coatings are gaining traction due to their reduced environmental impact, as they release fewer volatile organic compounds (VOCs) compared to traditional solvent-based coatings. Additionally, the use of nanotechnology in coil coatings is emerging as a promising development. Nano-coatings can provide enhanced durability, resistance to dirt and stains, and improved self-cleaning properties.

Moreover, manufacturers are increasingly focusing on improving the performance of coil coatings by enhancing their resistance to corrosion, UV radiation, and abrasion. There is also a growing emphasis on custom finishes that offer a unique look and feel for various applications, particularly in the construction and automotive sectors.

Regional Insights

The coil coatings market is geographically diverse, with demand concentrated in regions experiencing rapid industrialization and infrastructure development. North America and Europe are mature markets for coil coatings, with a strong presence of established manufacturers and end-users across construction, automotive, and home appliances sectors.

Asia-Pacific, however, stands out as the fastest-growing region for coil coatings. This can be attributed to the rapid industrialization, urbanization, and infrastructure projects in countries like China, India, and Southeast Asian nations. These regions are witnessing an increased demand for coil-coated metals in residential and commercial construction, as well as automotive manufacturing.

Challenges and Market Restraints

Despite the promising growth, the coil coatings market faces challenges such as fluctuating raw material prices, especially for steel and aluminum. The cost of coatings can also vary significantly depending on the type of resin used and the complexity of the finish. Additionally, the high initial capital investment required for setting up coil coating facilities and equipment poses a barrier to new entrants in the market.

Environmental regulations related to the use of solvents and the emissions of volatile organic compounds (VOCs) also represent challenges for manufacturers. Although there is a shift toward eco-friendly alternatives, meeting regulatory requirements while maintaining cost-effectiveness remains an ongoing concern for the industry.

Conclusion

The coil coatings market holds substantial potential for growth, driven by expanding industries such as construction, automotive, and home appliances. Technological advancements in coatings formulations and growing demand for eco-friendly solutions are shaping the future of the market. As urbanization and industrialization continue to rise, the demand for durable, cost-effective, and aesthetically pleasing coil-coated metals will persist, further enhancing the market’s scope in the coming years.

Comments

0 comment