views

The automotive axle market is undergoing significant transformation, driven by advancements in electric mobility, lightweight materials, and intelligent drivetrain technologies. With the increasing demand for fuel-efficient and high-performance vehicles, manufacturers are integrating cutting-edge innovations to enhance axle durability, efficiency, and functionality. As automotive technology evolves, axle systems are becoming more sophisticated, supporting the transition toward electric and autonomous vehicles.

Key Technological Advancements in the Automotive Axle Market

Development of Electric Axles (E-Axles)

The rise of electric vehicles (EVs) has led to the adoption of electric axle systems, which integrate electric motors, power electronics, and transmissions into a single compact unit. E-axles reduce the need for conventional drivetrains, improving energy efficiency while simplifying vehicle design. Leading manufacturers such as ZF Friedrichshafen and Dana Incorporated are introducing advanced e-axles to optimize performance in battery-electric and hybrid vehicles.

Lightweight and High-Strength Materials

Axle manufacturers are increasingly utilizing lightweight materials such as aluminum, high-strength steel, and carbon fiber composites to enhance vehicle efficiency. By reducing overall weight, these materials contribute to improved fuel economy and lower emissions. Companies like American Axle & Manufacturing are developing high-strength, lightweight axles that offer enhanced durability without compromising performance.

Integration of Smart Sensors and Predictive Maintenance

Advancements in sensor technology have enabled the development of smart axles capable of real-time monitoring and predictive maintenance. These systems use IoT-enabled sensors to track load distribution, temperature, and wear levels, ensuring enhanced safety and reduced maintenance costs. Smart axle technology is particularly beneficial for commercial and heavy-duty vehicles, where reliability and uptime are critical.

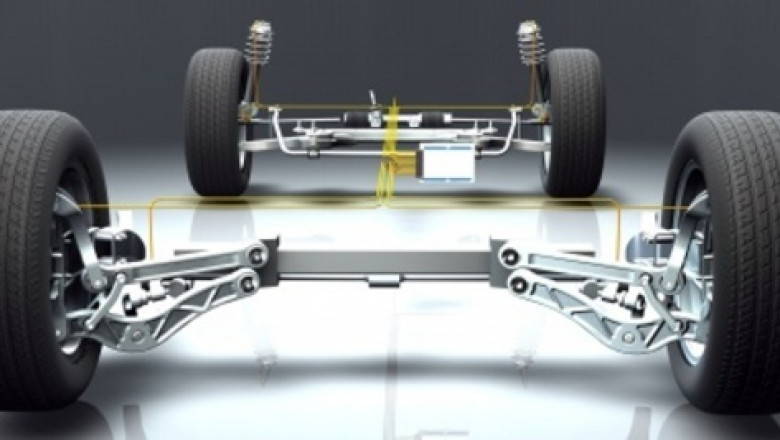

Enhanced Differentials and Torque Vectoring Systems

Modern axle systems are equipped with advanced differentials that enhance traction and stability. Torque vectoring technology allows power distribution between wheels for improved handling, particularly in high-performance and off-road vehicles. Manufacturers such as GKN Automotive and JTEKT Corporation are incorporating electronically controlled limited-slip differentials to optimize driving dynamics.

3D Printing and Advanced Manufacturing Techniques

The use of additive manufacturing (3D printing) and automation in axle production is revolutionizing the industry. These techniques allow for the creation of complex, high-precision axle components with reduced material waste and production costs. The implementation of Industry 4.0 technologies is enabling greater customization and faster prototyping for next-generation axle solutions.

Final Thoughts

Technological advancements in the automotive axle market are redefining the way axle systems function, improving efficiency, durability, and integration with modern vehicles. The shift toward electric mobility, lightweight materials, and intelligent drivetrain solutions is expected to shape the future of the industry. As automakers continue to push for innovation, axle manufacturers must invest in R&D and advanced manufacturing to stay ahead in a highly competitive market.

Comments

0 comment