views

In today’s competitive and high-precision manufacturing environment, achieving ultra-tight tolerances, exceptional surface finishes, and consistent part quality is more important than ever. One machining process that excels at all three is CNC Grinding a computer-controlled abrasive machining technique used for finishing metal and hard material components. Whether producing parts for aerospace, automotive, medical, or toolmaking applications, CNC grinding ensures maximum control, repeatability, and surface excellence.

In this comprehensive guide, we’ll explore the working principles, machine types, advantages, use cases, and best practices associated with CNC grinding, explaining why it has become indispensable in modern manufacturing workflows.

What Is CNC Grinding?

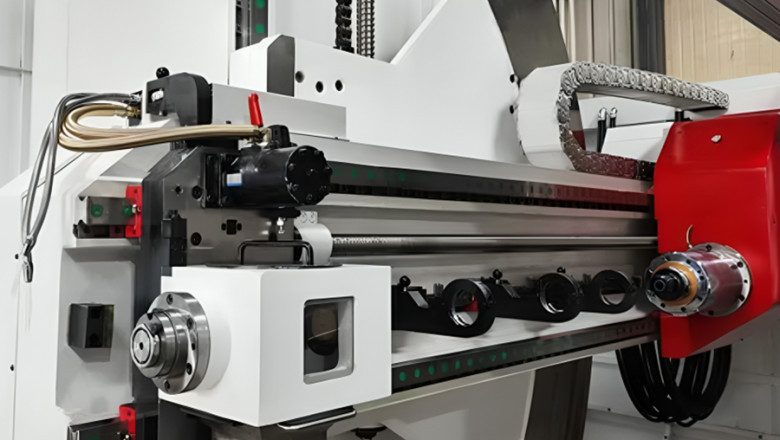

CNC (Computer Numerical Control) grinding is a precise machining process in which an abrasive wheel removes material from a workpiece under computer control. Unlike manual or conventional grinding, CNC grinding provides advanced automation and multi-axis movement, allowing the production of complex shapes and consistently accurate dimensions.

Grinding typically follows processes like CNC turning or milling, serving as the final step to refine surfaces, ensure flatness, and correct minor dimensional variances. The result is a high-quality finish that enhances part performance, durability, and aesthetics.

How CNC Grinding Works

CNC grinding machines consist of a grinding wheel, workholding fixtures, and computer-controlled motors. The CNC controller directs movement across one or more axes to achieve the desired shape and surface finish. Several variables influence the process:

-

Speed of the grinding wheel

-

Feed rate of the workpiece

-

Depth of material removed

-

Coolant flow to reduce heat and friction

Abrasive wheels made from materials like aluminum oxide, CBN (Cubic Boron Nitride), or diamond are chosen based on the workpiece material and finish requirements.

Common Types of CNC Grinding

Different grinding operations are employed depending on the geometry and material of the workpiece. Here are the main categories:

1. Surface Grinding

Used to create perfectly flat surfaces, surface grinding removes minimal material to achieve uniform thickness and smooth finishes. Ideal for base plates, precision blocks, and molds.

2. Cylindrical Grinding

Best for external or internal round components such as shafts, rollers, and bushings. Cylindrical grinding may involve single or multiple axes to handle complex profiles.

3. Centerless Grinding

In this process, the part is supported between two wheels (grinding and regulating) without the need for a center spindle. It is excellent for mass-producing round parts like pins and rods.

4. Tool and Cutter Grinding

Specialized for sharpening or producing tools such as end mills, drills, and reamers. These machines offer high flexibility and multi-axis motion for complex tool geometries.

Benefits of CNC Grinding

High Precision and Tight Tolerances

CNC grinding achieves tolerances as tight as ±0.001 mm, essential for aerospace, automotive, and medical applications where part accuracy directly impacts performance and safety.

Exceptional Surface Finish

Parts can be finished to surface roughness levels below Ra 0.2 µm, significantly reducing friction, wear, and failure in moving components.

Automation and Repeatability

CNC programming eliminates operator variability, enabling consistent results over short or long production runs with minimal manual supervision.

Versatility with Materials

From hardened steels and superalloys to ceramics and carbide, CNC grinding accommodates a wide range of materials, many of which are challenging to machine by conventional means.

Complex Geometries

Modern CNC grinders can machine intricate profiles and multi-step shapes that would be difficult or impossible to achieve manually.

Applications Across Industries

Aerospace

In the aerospace industry, reliability and dimensional accuracy are non-negotiable. CNC grinding is used to finish engine parts, turbine blades, hydraulic components, and gear systems.

Automotive

Precision parts such as crankshafts, camshafts, and gearbox components rely on grinding for their surface finish, roundness, and consistent diameter.

Medical Devices

Instruments like surgical scissors, orthopedic implants, and dental tools must meet strict surface quality and hygiene requirements, all achievable with CNC grinding.

Tool and Die

Toolmakers use grinding for sharpening and finishing punches, dies, and cutting tools. CNC grinding improves edge sharpness and extends tool life.

Electronics and Semiconductors

In miniature electronics, high-tolerance connectors, enclosures, and contact pins are ground to meet fine specifications and smoothness demands.

Design Considerations for CNC Grinding

To achieve optimal results and efficiency, parts should be designed with the grinding process in mind:

-

Allow for Wheel Access: Ensure sufficient clearance and geometry for grinding wheels to reach target surfaces.

-

Use Appropriate Materials: Materials should be suitable for grinding in terms of hardness, grain structure, and thermal properties.

-

Specify Tolerances Where Necessary: Over-specifying tolerances increases cost. Define only where required by function or fit.

-

Optimize Surface Finish Requirements: Match finish specifications with real-world needs to balance quality and productivity.

Working with experienced CNC grinding providers can also help fine-tune designs for manufacturability.

Best Practices for CNC Grinding

Choose the Right Abrasive

Use aluminum oxide for steel, silicon carbide for non-ferrous metals, and diamond or CBN for hard or heat-sensitive materials.

Apply Coolant Effectively

Coolant flow is critical to control heat, reduce wheel loading, and extend tool life. Ensure optimized coolant nozzles and pressure.

Maintain Machine Calibration

Grinding machines require precise calibration. Regularly check and adjust axis positioning, wheel wear, and tooling offsets.

Monitor Wheel Wear and Dress Frequently

A worn wheel can lead to poor finishes and dimensional errors. Dressing restores shape and maintains grinding performance.

Program Smartly

Efficient CNC programming reduces cycle time and minimizes thermal distortion. Use simulation tools to avoid collisions and verify tool paths.

Why Choose Professional CNC Grinding Services?

Outsourcing CNC grinding to experienced service providers like MYT Machining offers multiple benefits:

-

State-of-the-art equipment

-

In-house engineering expertise

-

Quality control systems and inspection reports

-

Rapid lead times and cost-efficient production

-

Custom solutions for complex or high-precision projects

By working with a trusted partner, manufacturers can achieve better quality, scalability, and cost control.

The Future of CNC Grinding

CNC grinding continues to evolve with integration of AI, real-time analytics, and machine learning for predictive maintenance and adaptive controls. Hybrid machining, combining grinding with additive or subtractive processes, is emerging to reduce setups and improve part complexity.

Increased adoption of robotics and automated part loading systems is also expanding grinding capabilities for high-volume production with less manual labor.

Conclusion

CNC grinding is a powerful and essential process in modern manufacturing, offering unmatched precision, surface quality, and consistency. From simple finishing jobs to producing complex geometries on hardened materials, CNC grinding plays a vital role across industries that demand reliability, repeatability, and tight dimensional control.

Comments

0 comment