views

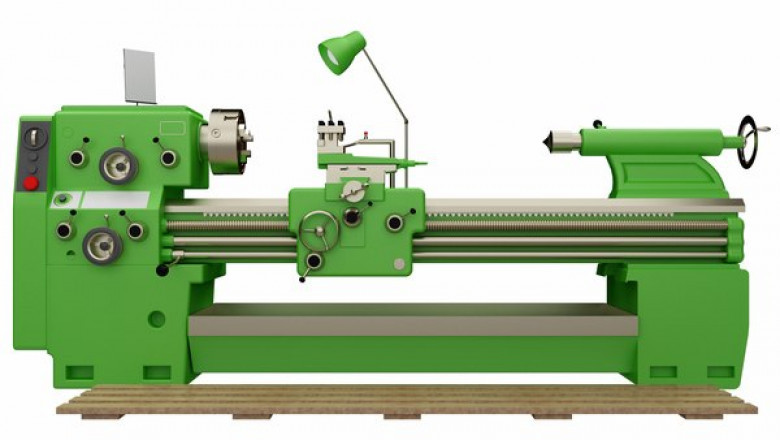

The lathe is one of the most versatile metalworking tools available. It can be used to shape metal through precision cutting and material removal processes. On a lathe, a workpiece is rotated and fed into a tool that cuts away excess material to create the desired shape or dimensions. With this simple yet flexible setup, hundreds of different lathe operations can be performed.

Parts Turning and Rotating

One of the most fundamental Lathe Machine operations is turning. This involves using the rotating tool to shape the workpiece into round forms like cylinders, cones, or balls. Parts like nuts, bolts, screws, tubing, and rods are commonly made through turning. The lathe also enables the turning of irregular shapes through the use of form tools or carbide inserts. Complex geometries with features like threading, tapers, or contours can all be formed.

Thread Cutting Capability

Another common application of the lathe is thread cutting. Internal and external threads of all types including metric, imperial, ACME, and specialty threads can be accurately cut on a lathe. Thread cutting attachments allow precise thread cutting on workpieces that then can be used to assemble parts with matching threads. Complex thread profiles like buttress or trapezoidal threads are also possible.

Grooving and Parting Off

Grooving is the process of cutting precise flat-bottom grooves into turned parts using special grooving tools. This can allow features like oil channels, keyways, or grooves for O-rings on shafts or cylinders. Parting off is used to separate individual parts from a larger workpiece stock. This cleanly cuts off turned pieces to the exact length needed. Parting tools allow easy production of multiples of the same precision part.

Boring and Reaming

Boring is the process of enlarging existing holes on a turned workpiece to precise sized bores using dedicated boring tools. This could be enlarging mounting holes or creating bores for bearings or bushings. Reaming then finishing the bores after boring for higher accuracy. Together, boring and reaming on a lathe allow production of parts with tight tolerance cylindrical bores or holes.

Facing and Chamfering

Through tool positioning and feed motion control, lathes enable facing, or creating a flat perpendicular surface on a workpiece. This can square off or true an end for precise mounting of other components. Chamfering uses special tools to cut angled edges or beveled surfaces at ends or corners of a lathe turned part. Features like chamfers aid assembly and prevent damage during handling.

Multi-point Turning Tools

Modern multi-point turning tools with triangular, square or hexagonal inserts have streamlined production. They allow cutting of complex profiles on a single pass that would otherwise require multiple setups. Common multi-point tools include diamond, square and triangular forms. They greatly boost the productivity of processes like grooving, facing or boring on a CNC lathe.

CNC Programming and Automation

Computer Numerical Control has transformed modern metal lathes. CNC lathes offer automated and repeatable machining through programmed code. This allows manufacturing complex parts in series with tight tolerances. Fanuc, Siemens and other control brands provide user-friendly interfaces for writing, verifying and running CNC programs on lathes. Automated tool changers and multi-axis motion also boost efficiency of CNC lathes compared to manual machines.

Applications of Lathe Machining

Precision metal lathe machining has wide industrial applications. Common areas include automotive (pistons, crankshafts), aerospace (bolts, shafts), hardware (screws, nuts), medical (artificial joints, implants), electronics (connectors), energy (pump parts), and general machining. Anything requiring consistently shaped metal parts in volumes is a potential application of lathe machining processes. Their versatility has sustained lathes as one of the most universal machine tools for over two centuries.

Get this Report in Japanese Language- 旋盤

Get this Report in Korean Language- 선반 기계

About Author-

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Known for her strong SEO background, she skillfully blends SEO strategies with insightful content. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

Comments

0 comment