views

What’s Driving the Automotive Air Compressor Market in 2024? Key Trends and Industry Insights

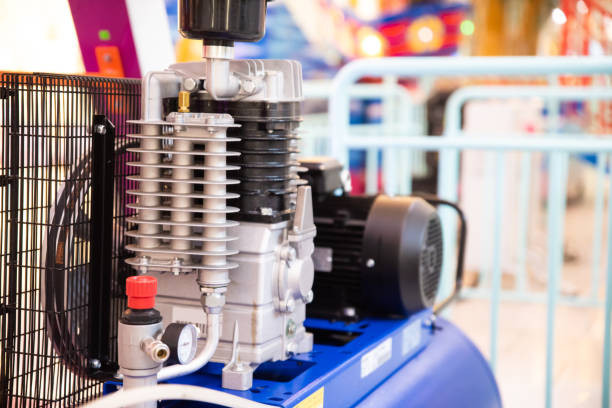

The automotive air compressor market has been evolving rapidly, fueled by advancements in vehicle technology, sustainability concerns, and increasing demand for fuel-efficient solutions. As of 2024, the market is witnessing a significant shift, driven by innovations in electric vehicle (EV) technology, regulatory changes, and strategic expansions by key industry players. But what exactly is shaping this dynamic sector? Let’s explore the latest developments, trends, and challenges in the automotive air compressor market.

1. What Are the Key Factors Fueling the Automotive Air Compressor Market Growth?

Automotive air compressors play a crucial role in various vehicle applications, from tire inflation and air suspension systems to braking mechanisms in heavy-duty vehicles. Several factors are contributing to the market’s expansion:

A. Rising Demand for Electric Vehicles (EVs)

With the global shift toward sustainability, EV production has surged, requiring advanced air compressor technologies for thermal management and braking systems. Unlike traditional internal combustion engine (ICE) vehicles, EVs rely on electric air compressors to power air conditioning and braking systems. This has led to increased demand for compact, energy-efficient air compressors.

B. Stricter Emission Regulations

Governments worldwide are enforcing stringent emission norms, pushing automakers to adopt fuel-efficient and eco-friendly air compressor technologies. Traditional belt-driven compressors consume more fuel, leading to higher emissions, whereas electric compressors offer a more sustainable alternative.

C. Growth in Commercial and Heavy-Duty Vehicles

The logistics and transportation sectors have seen steady growth post-pandemic, driving demand for commercial vehicles. Air compressors are critical for air brakes in trucks and buses, making them an essential component in this segment.

D. Advancements in Smart and Lightweight Air Compressors

Modern vehicles require compact and efficient compressors that contribute to overall weight reduction and fuel savings. Leading manufacturers are investing in lightweight, durable materials and smart compressor systems that optimize performance through real-time data monitoring.

2. What Are the Latest Innovations in Automotive Air Compressors?

The automotive air compressor industry has witnessed several groundbreaking innovations in 2024, shaping its future.

A. Development of Oil-Free Air Compressors

Oil-free compressors are gaining popularity due to their low maintenance, increased efficiency, and environmental benefits. These compressors eliminate the risk of oil contamination, making them ideal for hybrid and electric vehicles.

B. Integration of AI and IoT for Predictive Maintenance

Manufacturers are incorporating artificial intelligence (AI) and the Internet of Things (IoT) into air compressors to enable predictive maintenance. Sensors monitor compressor performance, providing real-time alerts on potential failures, reducing downtime and operational costs.

C. High-Efficiency Rotary and Scroll Compressors

Rotary and scroll air compressors are replacing traditional piston compressors due to their higher efficiency, quieter operation, and compact size. These innovations cater to both passenger and commercial vehicles, improving overall performance and energy savings.

D. Hydrogen-Powered Air Compressors for Fuel Cell Vehicles

With the rise of hydrogen fuel cell vehicles, air compressor technology has also evolved. Hydrogen-powered compressors help optimize fuel cell efficiency by ensuring proper airflow, enhancing vehicle performance. This innovation aligns with the global push toward zero-emission transportation.

3. What Are the Recent Market Trends and Strategic Developments?

A. Mergers and Acquisitions

In 2024, the automotive air compressor market has witnessed several high-profile mergers and acquisitions. Major players are acquiring smaller companies to expand their product portfolios and strengthen their market presence. For example, Atlas Copco’s acquisition of a German compressor manufacturer has helped the company enhance its offerings in electric air compressors.

B. Expansion of Manufacturing Facilities

Leading air compressor manufacturers are expanding their production facilities to meet the growing demand. Companies like Sullair and Ingersoll Rand have announced new plants in Asia and North America, targeting the expanding EV marke

C. Increasing Investment in R&D

Automotive giants are investing heavily in research and development (R&D) to produce energy-efficient compressors. Bosch and Valeo, for instance, are working on next-generation electric compressors that promise higher efficiency and lower power consumption.

D. Partnerships Between Automakers and Component Suppliers

To stay competitive, automakers are forming strategic partnerships with air compressor manufacturers. Tesla and Hanon Systems, for example, have collaborated on developing electric air compressors for Tesla’s next-gen EV models.

4. What Are the Challenges Facing the Automotive Air Compressor Industry?

Despite its promising growth, the industry faces several challenges that could impact its trajectory.

A. Supply Chain Disruptions

The ongoing semiconductor shortage and raw material supply issues have affected compressor production. Manufacturers are struggling to source critical components, leading to longer lead times and increased costs.

B. High Initial Investment in Electric Air Compressors

While electric air compressors offer long-term benefits, their initial cost remains a barrier for some automakers. The transition from traditional compressors to electric models requires significant investment in new production lines and technologies.

C. Competition From Alternative Technologies

Hydraulic and pneumatic systems are emerging as alternatives to air compressors in certain vehicle applications. Automakers exploring new braking and suspension technologies may reduce reliance on traditional air compressors.

D. Environmental Regulations on Compressor Manufacturing

Governments are imposing stricter environmental regulations on manufacturing processes, requiring compressor companies to adopt sustainable production practices. Compliance with these regulations often results in increased production costs.

5. What Is the Future Outlook for the Automotive Air Compressor Market?

The automotive air compressor market is expected to witness continued growth, driven by technological advancements and the rising adoption of EVs. Here are some key projections for the future:

· EV Dominance: The demand for electric air compressors will continue to rise as EV adoption increases. By 2030, the majority of new air compressor technologies will be designed specifically for electric and hybrid vehicles.

· Smart and Connected Systems: AI-powered compressors with self-diagnostic capabilities will become the industry standard, reducing maintenance costs and improving vehicle efficiency.

· Sustainable Manufacturing: Companies will prioritize eco-friendly materials and energy-efficient manufacturing processes to comply with global sustainability goals.

· Market Expansion in Asia-Pacific: The Asia-Pacific region, particularly China and India, will see significant growth in air compressor manufacturing due to rising vehicle production and government incentives for EVs.

Final Thoughts

The automotive air compressor market is undergoing a transformation, driven by electrification, smart technology, and environmental considerations. While challenges like supply chain disruptions and high initial costs persist, the industry’s future remains promising. With continued investments in R&D and strategic collaborations, the market is poised for sustained growth in the coming years.

So, what’s next for automotive air compressors? As vehicle technology continues to evolve, we can expect even more groundbreaking innovations that will redefine how air compressors function in modern automobiles.

Comments

0 comment