views

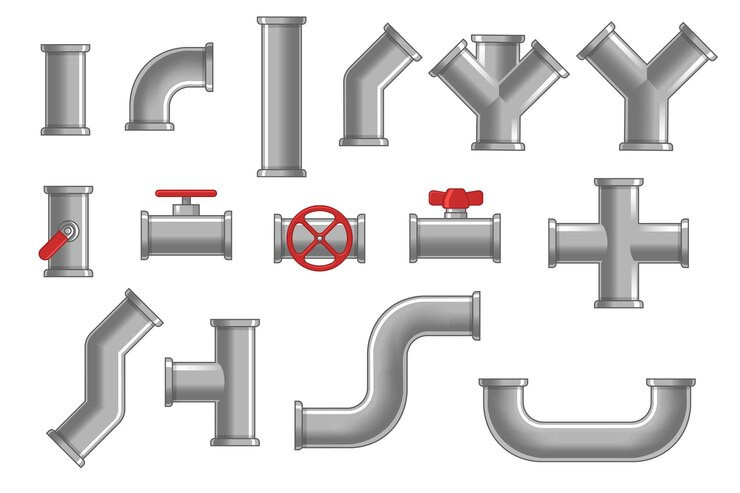

Concrete pump pipelines are vital in the construction industry as they ensure efficient transportation of concrete from one place to another without lumps or damage. Recently, manufacturers in Delhi have utilized the latest innovation to enhance durability, functionality, and efficiency. Among these companies, those that can specifically Best Concrete Pump Pipeline Bend manufacture are the one providing quality and reliability features. It is a review of the latest technology by which concrete pump pipeline manufacturing is undergoing a transformation in Delhi.

H2: Advanced Materials for Enhanced Durability

The most innovative use of concrete pump pipeline manufacture is the application of advanced materials. More and more manufacturers are using high-strength alloys, abrasion-resistant steels, and reinforced composites to produce pipelines that are highly resistant to extreme wear and tear. Such an emphasis on materials ensures not only the increased lifespan of the pipelines but also the decrease in maintenance costs for end-users.

Integration of polymer linings within pipelines has gained ground. The linings help reduce friction during concrete flow, leading to smooth operations and preventing blockages. Such developments have ensured that Delhi-based manufacturers are miles ahead in construction projects offering durable solutions.

H2: Precision Engineering for Superior Parts

Delhi-based manufacturers are using precision engineering technologies like CNC machining and laser cutting to produce top-of-the-line concrete pump parts. Best Concrete Pump Parts Manufacturing companies are now turning to these technologies in order to provide a stable, hassle-free product line and also maintain the original dimensions of their products.

This is well illustrated by pipeline clamps and connectors whose fabrication requires an exceptional degree of accuracy to provide an exact fit. Precision manufactured components have made the concrete pumping system much more efficient than earlier designs and therefore it has gained more prominence in contemporary construction ventures.

H2: Smart Technologies in Manufacturing

The integration of smart technologies was a game-changer in the concrete pump pipeline manufacturing business. With automation and IoT (Internet of Things) and AI-powered quality control systems, manufacturers are now able to streamline their production processes. The technologies allow the real-time monitoring of pipeline dimensions, material properties, and the quality of the product.

Delhi's manufacturers are also experimenting with 3D printing technologies for prototyping and small-batch production. This innovation enables rapid design iterations and helps bring custom solutions to market faster. Such advancements underscore the industry’s commitment to staying ahead of the curve.

H2: Focus on Specialized Components

Innovations among manufacturers in Delhi are highly fuelled by the need for specialized components, such as rubber hoses and forged clamps. Best Concrete Pump Rubber Hose products, for example, have been developed to achieve maximum flexibility while also being abrasion-resistant. Now designed to withstand high pressures of concrete pumping, they maintain durability during lengthened usage periods.

Similarly, best Concrete Pump clamp (Forged) has evolved significantly. Forged clamps have strength and precision locking, which provides excellent connections even under high-pressure conditions. This attention to specialized components is a reflection of the industry's commitment to meeting diverse construction needs.

H2: Eco-Friendly Manufacturing Practices

Another significant innovation is the inclusion of a green approach to manufacturing. More manufacturers in Delhi are now focusing on cutting carbon emissions by harnessing eco-friendly inputs and energy-efficient production techniques. Recycling of raw materials and proper management of wastes have become an essential process part of their operations, consistent with the global trend toward environmental sustainability.

These efforts not only benefit the environment but also enhance the reputation of manufacturers, making them the preferred choice for environmentally conscious clients.

H2: Customization for Diverse Applications

Customization has been the most trending aspect in the concrete pump pipeline industry. Manufacturers in Delhi offer solutions that are specifically tailored to suit the requirements of their clients. Whether it's a unique design for pipelines or bespoke components like bends, clamps, and hoses, customization ensures optimal performance in various construction scenarios.

Specialists in Best Concrete Pump Pipeline Bend Manufacturing and other pipeline components are leveraging advanced CAD (Computer-Aided Design) tools to create custom solutions with unparalleled precision. This focus on customization highlights the industry's adaptability to evolving client demands.

H2: Conclusion

The concrete pump pipeline manufacturing industry in Delhi is in the transformation phase. The basis for this change has been driven by technological development, eco-friendly practices, and specialized components. Best Concrete Pump Parts Manufacturing and Best Concrete Pump Pipeline Bend Manufacturing companies are embracing innovation to deliver better products that will meet the ever-growing demands of the construction sector.

With the advent of cutting-edge technologies in manufacturers, clients can look forward to more efficient, durable, and customized solutions. Whether it's the development of Best Concrete Pump Rubber Hose or the innovation in best Concrete Pump clamp (Forged), the future of concrete pump pipeline manufacturing in Delhi is brighter than ever.

Comments

0 comment