views

Vietnam Aluminium Market Companies Leading the Charge in Carbon Footprint Reduction

Introduction

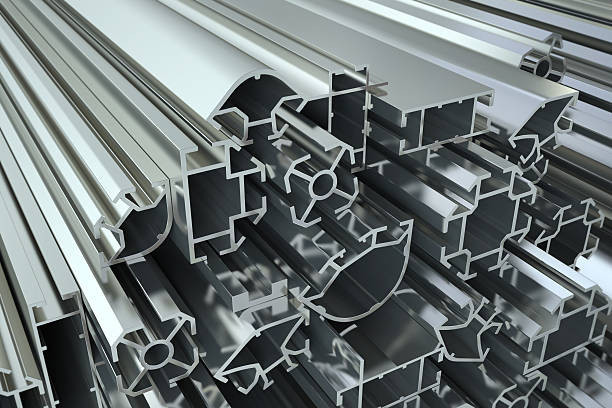

The Vietnam Aluminium Market has been a key player in the nation’s rapid industrialization, contributing to the growth of sectors such as construction, automotive, and electronics. However, as global sustainability trends continue to shape industries worldwide, the demand for reducing carbon emissions and improving environmental practices has become more pronounced. Aluminium production, traditionally energy-intensive, is being increasingly scrutinized for its environmental impact.

Vietnam’s aluminium companies are taking this challenge head-on by adopting innovative solutions and strategies to reduce their carbon footprint. This article will explore how the leading aluminium companies in Vietnam are embracing sustainability, reducing emissions, and contributing to a greener future for the country’s aluminium sector.

The Environmental Impact of Aluminium Production

Aluminium production is energy-intensive and can be a significant source of carbon emissions, especially during the extraction of bauxite, refining into alumina, and the smelting process that creates aluminium. According to the International Aluminium Institute, about 70% of aluminium's emissions come from its production process, primarily due to the energy used in smelting.

Given the urgency of tackling climate change, the aluminium industry globally has faced mounting pressure to improve its environmental performance. In Vietnam, where industrial growth has been accompanied by concerns over sustainability, the demand for eco-friendly aluminium production is on the rise. The good news is that many companies are stepping up their efforts to reduce their carbon footprint while maintaining high-quality output.

Leading Aluminium Companies in Vietnam and Their Carbon Footprint Reduction Initiatives

Several prominent aluminium companies in Vietnam are making strides in reducing their carbon footprint through the adoption of new technologies, the use of renewable energy, and a greater focus on recycling. Below, we highlight some of the top players leading the charge in sustainable aluminium production.

1. East Asia Aluminium Company Limited

East Asia Aluminium Company Limited (EAAL) is one of Vietnam’s leading aluminium manufacturers, well-known for producing high-quality aluminium products, such as profiles, sheets, and coils. This company has placed a strong emphasis on reducing its environmental impact, with several initiatives focused on lowering carbon emissions.

Renewable Energy Integration

EAAL has integrated renewable energy sources into its production process, reducing reliance on fossil fuels. By utilizing solar panels at its manufacturing plants and purchasing green energy from certified sources, the company has significantly reduced its greenhouse gas emissions. This shift towards renewable energy is part of their broader strategy to make their operations more sustainable.

Energy-Efficient Production Technologies

In addition to using renewable energy, EAAL has invested in energy-efficient technologies to reduce its energy consumption during production. The company’s focus on improving the energy efficiency of its smelting and extrusion processes has helped lower the overall carbon intensity of its aluminium production. This has allowed EAAL to meet both local and international environmental standards while providing a high-quality product to its customers.

Recycling and Circular Economy Focus

EAAL is also placing significant importance on aluminium recycling, a practice that greatly reduces carbon emissions compared to the production of primary aluminium. By implementing advanced recycling technologies, the company ensures that a large portion of its aluminium is sourced from recycled material, thereby reducing the need for energy-intensive virgin aluminium production.

2. Tan Ky Aluminium Corporation (TKAC)

Tan Ky Aluminium Corporation (TKAC) is another prominent player in Vietnam’s aluminium sector, recognized for its commitment to sustainability and environmental responsibility. The company produces a wide range of aluminium products, including profiles, sheets, and rolls, for industries such as construction, transportation, and packaging.

Adoption of Green Manufacturing Processes

TKAC has adopted several green manufacturing practices to mitigate the environmental impact of its operations. For example, the company uses advanced water treatment systems to reduce the amount of water wasted during production, and its waste management system ensures that materials are reused or recycled whenever possible.

Investment in Clean Technologies

In a bid to lower emissions, TKAC has invested in clean production technologies, including more efficient furnaces and better heat recovery systems. These upgrades help minimize energy consumption and reduce carbon emissions, making their production processes more environmentally friendly.

Carbon Neutral Goals

TKAC has set ambitious carbon neutral goals, aiming to offset its carbon emissions through the purchase of carbon credits and investing in reforestation projects. Their carbon-neutral commitment is aligned with global sustainability standards and positions them as a leader in sustainable aluminium production in Vietnam.

3. Viet Duc Aluminium Company

Viet Duc Aluminium is another leading manufacturer in Vietnam, specializing in aluminium products for the construction and manufacturing industries. The company has been proactive in implementing strategies to reduce its carbon footprint while enhancing its competitiveness in both domestic and international markets.

High-Efficiency Manufacturing Techniques

Viet Duc Aluminium has integrated high-efficiency production technologies into its operations, such as automated systems and energy-efficient machinery. These advancements have led to reduced energy consumption and a decrease in overall emissions. By continually optimizing its production processes, Viet Duc Aluminium aims to lower its carbon intensity and contribute to the global effort to combat climate change.

Focus on Recycling

Viet Duc Aluminium also emphasizes the importance of recycling in its sustainability efforts. The company sources a significant portion of its raw materials from recycled aluminium, which uses 95% less energy compared to producing new aluminium from bauxite. This not only helps to reduce emissions but also contributes to the circular economy by keeping aluminium in use for longer periods.

Collaboration with Sustainable Partners

Viet Duc Aluminium has partnered with various stakeholders, including local environmental organizations and international sustainability bodies, to adopt best practices for carbon footprint reduction. These collaborations help the company stay updated on the latest innovations in green technologies and ensure its compliance with environmental regulations.

4. Aluminum Vietnam Joint Stock Company (ALVINA)

ALVINA is one of the newer entrants in Vietnam’s aluminium market but has quickly gained recognition for its commitment to sustainability. The company focuses on producing aluminium products for the construction and automotive sectors and is dedicated to reducing its environmental impact.

Commitment to Low-Carbon Technologies

ALVINA has implemented low-carbon technologies, including the use of electric arc furnaces (EAF) in the production process. Electric arc furnaces are more energy-efficient and emit fewer carbon emissions compared to traditional methods of aluminium smelting, contributing to the company’s overall goal of reducing its carbon footprint.

Sustainable Sourcing and Supply Chain

The company has also made significant efforts to ensure that its supply chain is as sustainable as possible. ALVINA works closely with suppliers to source raw materials from ethical and eco-friendly sources, ensuring that the environmental impact of its products is minimized at every stage of the production process.

Key Strategies for Carbon Footprint Reduction in Vietnam’s Aluminium Market

Several common strategies have emerged across the Vietnamese aluminium sector in response to the pressing need for sustainability:

1. Renewable Energy Adoption: A significant shift towards renewable energy sources is taking place within the aluminium sector. Many companies are utilizing solar and wind energy to power production processes, reducing their reliance on carbon-intensive fossil fuels.

2. Energy-Efficient Manufacturing: Upgrading manufacturing technologies to improve energy efficiency is a top priority for many Vietnamese aluminium companies. By implementing automated systems, energy-efficient furnaces, and heat recovery systems, companies can significantly reduce their carbon emissions.

3. Recycling and Circular Economy: Recycling plays a crucial role in lowering the carbon footprint of aluminium production. Recycled aluminium requires only 5% of the energy needed to produce new aluminium from raw materials, making it a key component of carbon footprint reduction strategies.

4. Carbon Offset and Neutrality Programs: Several companies are investing in carbon offset programs, such as reforestation initiatives or carbon credits, to balance out the emissions they generate. These efforts are aligned with the global shift towards carbon neutrality.

5. Government Regulations and Industry Standards: Vietnam’s government has introduced policies and regulations that encourage companies to adopt sustainable practices, including incentives for renewable energy adoption and waste reduction. Additionally, global industry standards, such as the Aluminium Stewardship Initiative (ASI), are driving companies to meet higher environmental and social governance (ESG) requirements.

Conclusion

The Vietnamese aluminium sector is undergoing a significant transformation, with companies leading the charge in carbon footprint reduction. From large players like East Asia Aluminium Company Limited to emerging firms like ALVINA, the focus on sustainability is reshaping the industry. By adopting renewable energy, improving energy efficiency, investing in recycling, and exploring new low-carbon technologies, Vietnam’s aluminium companies are not only reducing their environmental impact but also positioning themselves as global leaders in green manufacturing.

As the demand for environmentally responsible products continues to grow, these companies will continue to innovate and play a key role in the global shift towards a more sustainable and low-carbon future. The efforts of these Vietnamese aluminium manufacturers serve as a model for other industries to follow as they work towards reducing their carbon footprint and contributing to a healthier planet.

Comments

0 comment