views

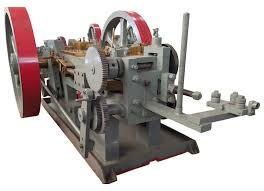

The cold forging machine market has witnessed notable advancements in recent years, owing to its critical role in producing high-strength, precision-engineered metal components. Used extensively in sectors such as automotive, aerospace, industrial equipment, and consumer electronics, cold forging enables efficient mass production with reduced material waste and energy usage. As global demand for durable and lightweight components continues to rise, the market is being driven forward by several accelerators—key forces that are catalyzing innovation, adoption, and scalability in the industry. This article explores the major accelerators propelling growth and transformation in the cold forging machine market.

Increasing Demand for Lightweight and High-Strength Components

One of the most powerful growth accelerators in the market is the increasing global demand for lightweight yet durable components, especially in the automotive and aerospace industries. Cold forging provides superior mechanical properties such as high tensile strength, fatigue resistance, and dimensional accuracy, making it ideal for manufacturing gears, shafts, bolts, and structural components.

With rising concerns about fuel efficiency and emission standards, manufacturers are shifting toward lighter materials and precision parts that can enhance performance. Cold forging machines are well-suited to meet this requirement, thereby fueling their adoption across critical manufacturing segments.

Expansion of the Electric Vehicle (EV) Sector

The rapid growth of the electric vehicle (EV) industry is acting as a significant accelerator for the cold forging machine market. EVs require a new set of components, including electric motor parts, battery housing connectors, fasteners, and transmission components—all of which can be efficiently manufactured through cold forging.

Unlike traditional internal combustion engines, EVs emphasize compactness, lightweight design, and high electrical conductivity—all attributes that cold forging can accommodate. As EV production ramps up globally, demand for cold forging solutions is expected to increase correspondingly.

Advancements in Automation and Smart Manufacturing

The integration of automation and smart technologies into cold forging machines has become a major accelerator of productivity and efficiency. Automated handling systems, real-time process monitoring, and CNC-controlled dies now enable faster setup, reduced error margins, and consistent product quality.

Smart cold forging machines also support predictive maintenance and digital quality control, allowing manufacturers to minimize downtime and scrap rates. These advancements are especially beneficial in high-volume production environments, giving manufacturers a compelling reason to invest in modern cold forging systems.

Government Initiatives Supporting Manufacturing Modernization

Governments in several countries are launching initiatives and offering incentives to boost local manufacturing capabilities and advanced production technologies. Programs focused on Industry 4.0, energy efficiency, and import substitution have encouraged manufacturers to upgrade their equipment—including cold forging machines.

These initiatives often include financial support, tax relief, or grants for adopting energy-efficient and high-precision technologies. Such policy-driven support reduces the burden of capital expenditure, accelerating the adoption of cold forging machines in both developed and developing economies.

Growing Focus on Sustainability and Energy Efficiency

Cold forging is inherently more environmentally friendly than other metal forming processes like hot forging or machining. It operates at room temperature, consumes less energy, and generates less waste material. These characteristics make it highly attractive in a time when industries are under increasing pressure to reduce their environmental impact.

As global manufacturers prioritize sustainability goals, cold forging emerges as a preferred method that aligns with green manufacturing practices. This push toward eco-conscious production acts as a strong accelerator, particularly for companies looking to improve their ESG (Environmental, Social, and Governance) performance.

Rising Adoption in Emerging Economies

Emerging markets in Asia, Latin America, and Eastern Europe are investing heavily in industrial infrastructure, creating new demand for cold forging machines. As local automotive, aerospace, and construction sectors expand, the need for cost-effective, high-performance metal components is also increasing.

The presence of low-cost labor and supportive industrial policies makes these regions attractive for cold forging investments. Local manufacturers are increasingly recognizing the value of cold forging for improving product strength and reducing material waste, further accelerating market penetration.

Technological Innovation in Tooling and Die Materials

Another critical accelerator is the innovation in die and tooling materials used in cold forging. The development of advanced coatings, high-speed steels, and carbide dies has significantly increased tool life and allowed for the forming of more complex geometries.

Longer tool life and greater process reliability reduce overall production costs and downtime. This encourages manufacturers to use cold forging for a wider range of applications, thereby increasing demand for high-performance machines capable of handling these innovations.

Growth in Industrial Machinery and Infrastructure Projects

The global increase in infrastructure development and industrial machinery manufacturing is further supporting market expansion. Cold forging machines are essential for producing the mechanical components and fasteners used in construction equipment, energy systems, and heavy-duty machines.

As countries invest in renewable energy, smart cities, and public transportation, the requirement for high-strength, fatigue-resistant parts grows. Cold forging machines provide the necessary output quality and efficiency to meet these demands, reinforcing their relevance in large-scale industrial supply chains.

Conclusion

The cold forging machine market is entering a phase of accelerated growth, driven by a convergence of technological, economic, and environmental factors. From the rise of electric vehicles and automation to sustainability goals and infrastructure development, multiple accelerators are propelling the adoption and advancement of cold forging technology.

By investing in innovation, expanding into emerging markets, and embracing smart manufacturing principles, industry players can harness these accelerators to unlock new opportunities. As these drivers continue to evolve, the cold forging machine market is poised for sustained global expansion and transformation in the years ahead.

Comments

0 comment