views

Industrial Boilers Market is Estimated to Witness Growth Owing to IoT Automation

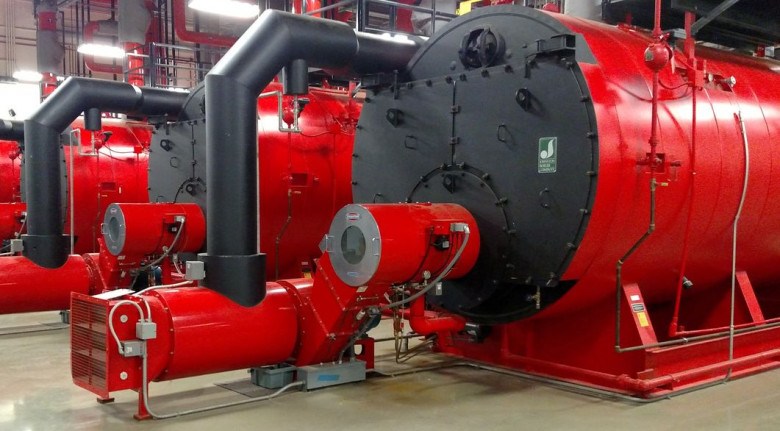

Industrial boilers are robust, high-capacity units designed to generate steam or hot water for a variety of applications across sectors such as power generation, chemical processing, oil and gas, pulp and paper, and food and beverage. These systems convert energy sources—natural gas, coal, biomass, or electricity—into thermal energy, supporting heating, sterilization, drying, and propulsion processes. Modern industrial boilers boast advanced control systems, enhanced heat exchange surfaces, and emissions reduction technologies that improve thermal efficiency, lower fuel consumption, and comply with stringent environmental regulations.

The integration of modular designs and compact footprints facilitates easier installation and maintenance, while safety features such as pressure relief valves and automated shutoffs mitigate operational risks. As manufacturers pursue energy efficiency and sustainability goals, demand grows for boilers capable of delivering consistent performance, rapid start-up times, and seamless integration with facility monitoring systems. This combination of reliability, performance, and compliance underscores the need for continuous market research and market insights to inform procurement strategies and identify Industrial Boilers Market opportunities.

The industrial boilers market is estimated to be valued at USD 18.32 Bn in 2025 and is expected to reach USD 25.61 Bn by 2032, growing at a compound annual growth rate (CAGR) of 4.9% from 2025 to 2032.

Key Takeaways

Key players operating in the Industrial Boilers Market are:

-AMEC Foster Wheeler PLC

-Siemens AG

-Thermax Limited

-Harbin Electric Corporation

-Bharat Heavy Electricals Limited

These market companies lead in product innovation, service networks, and global presence, shaping market share through strategic partnerships and tailored solutions.

The Industrial Boilers Market presents significant market opportunities driven by rising energy consumption in emerging economies, increased demand for waste heat recovery systems, and incentives for clean-energy infrastructure upgrades. Growth strategies center on customizing boiler packages for small-scale industries and offering boiler-as-a-service models. Moreover, expanding applications in district heating and process industries create new revenue streams. Market insights suggest that expanding into underpenetrated regions such as Southeast Asia and Latin America could boost industry size and business growth, while collaboration with renewable energy projects may foster hybrid systems combining biomass and fossil-fuel boilers.

Technological advancements in IoT automation are revolutionizing boiler operations by enabling real-time monitoring, predictive maintenance, and remote diagnostics. Smart sensors collect data on pressure, temperature, and fuel flow, feeding analytics platforms to optimize combustion efficiency and preempt system failures. Connectivity with cloud-based dashboards empowers plant managers to adjust setpoints, track energy usage, and generate compliance reports. This digital transformation enhances operational uptime, reduces unplanned downtime costs, and aligns with market trends toward Industry 4.0. As a result, IoT-enabled boilers deliver higher throughput, lower emissions, and a competitive edge for market players.

Market drivers

One of the primary market drivers for the Industrial Boilers Market is the stringent environmental regulations and targets for carbon reduction imposed by governments worldwide. Regulatory bodies are mandating lower NOx and CO₂ emissions, which compels industries to upgrade legacy boilers or install high-efficiency systems. The push for cleaner combustion technologies and low-carbon fuels—such as natural gas, biomass, and hydrogen blends—further accelerates replacement cycles and retrofit projects. Additionally, rising energy prices incentivize businesses to invest in boilers with superior thermal performance and waste heat recovery units. These factors jointly boost capital expenditure on advanced boiler installations and service contracts, fostering market growth. Continuous enhancements in boiler design, such as economizers, condensers, and integrated control panels, support compliance and cost savings, thus driving higher adoption rates and expanding the market scope over the forecast period.

Current Challenges

The industrial boilers market faces several market challenges that stem from evolving energy regulations and tightening emission standards. Rising fuel costs and fluctuating raw material prices exert pressure on manufacturers’ profit margins and complicate accurate market forecast. A detailed market analysis reveals that inefficient legacy systems struggle to meet increasing efficiency benchmarks, driving demand for retrofitting or replacement. At the same time, a shortage of skilled technicians and engineers hampers installation, commissioning and after-sales maintenance. Supply chain disruptions—exacerbated by geopolitical tensions—have led to delays in component delivery, constraining production schedules and impeding business growth. Meanwhile, rapid technological advancements in digital monitoring and predictive maintenance create both opportunities and restraints: companies that fail to invest risk falling behind on market trends, yet high integration costs deter smaller players from adoption. To navigate these dynamics, stakeholders must align with sustainable energy drivers and streamline operations through data-driven tools, balancing near-term constraints against long-term market growth goals.

SWOT Analysis

Strength: Industrial boilers benefit from a well-established manufacturing base and decades of field experience, delivering robust, high-efficiency designs that cater to diverse end-user requirements. This proven track record underpins solid market trust and ongoing adoption in power, petrochemical and manufacturing sectors.

Weakness: High upfront capital expenditure and lengthy installation cycles discourage small-scale buyers, limiting penetration into less-developed segments. Additionally, legacy fire-tube and water-tube models often lack integrated digital controls, reducing real-time performance optimization.

Opportunity: Growing emphasis on decarbonization opens avenues for advanced biomass- and hydrogen-fueled boiler systems, tapping into emerging sustainable energy initiatives. The rising focus on smart instrumentation and IoT-based predictive maintenance offers potential to upsell digital service packages.

Threats: Intensifying regulatory scrutiny on NOx and CO2 emissions may render older boiler fleets non-compliant, triggering costly retrofits or early replacements. Further, competition from alternative heating technologies—such as electric heat pumps and waste-to-energy systems—poses a threat to traditional steam and hot-water boiler applications.

Geographical Regions

Value Concentration: North America and Western Europe currently hold significant market share in the industrial boilers segment, driven by stringent environmental regulations and high industrial electricity prices that favor efficient steam-generation solutions. Mature manufacturing hubs in Germany, the UK and the US boast extensive aftermarket service networks, ensuring rapid response times and boosting local market confidence. Asia Pacific also contributes a sizable share, led by established chemical and power plants in China and Japan that demand large-scale boiler installations. Together, these regions account for the lion’s share of global boiler revenues due to their advanced infrastructure and early adoption of emission-control technologies.

Fastest-Growing Region: The Middle East & Africa region is emerging as the fastest growing market for industrial boilers, propelled by expanding petrochemical complexes and burgeoning power-generation capacity in Gulf Cooperation Council countries. Ambitious infrastructure projects in Saudi Arabia and the UAE—focused on reducing reliance on gas turbines—are driving strong demand for high-pressure steam boilers. Simultaneously, rising investments in desalination plants and industrial parks across North Africa are accelerating uptake. Favorable government incentives and long-term market forecast projections further reinforce this growth trajectory.

‣ Get this Report in Japanese Language: 産業用ボイラー市場

‣ Get this Report in Korean Language: 산업용보일러시장

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)