views

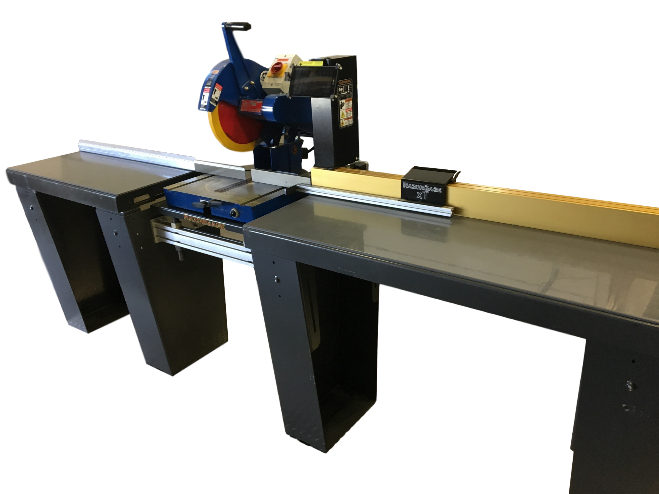

When it involves precision and consistency in woodworking or metal fabrication, the controversy among automatic chop saws and guide saws stays a hot subject matter. While traditional guide saws have long served professional craftsmen, current automatic chop saws are gaining reputation due to their efficiency and technological advancements. But how do they evaluate in terms of accuracy? Below, we explore the subject in 10 key points to apprehend which tool gives the higher aspect in precision and reliability.

1. Precision Cuts: Manual Skill vs. Mechanical Programming

Manual saws heavily depend on the operator’s ability. A seasoned user can obtain exceedingly correct cuts, but moderate hand movements or misjudgments can nonetheless result in variations. In contrast, automated chop saws use computer-controlled settings that allow for genuine reducing angles and dimensions, appreciably lowering the margin for human errors. This mechanical consistency offers higher precision, mainly in repetitive responsibilities.

2. Repetition and Consistency in Cuts

One of the major blessings of an automatic chop is its ability to duplicate the identical reduction more than one time with pinpoint accuracy. Manual saws, even in the arms of a skilled operator, may also show minor variations after repeated use because of fatigue or moderate variations in positioning. Automatic structures are designed to preserve uniformity throughout lots of cuts, making them the desired preference for mass manufacturing.

3. Error Margin Comparison

In sensible terms, the mistake margin of a fantastic guide saw is often inside 1/16th of an inch, assuming perfect situations and a skilled user. However, an automated chop saw can preserve a blunders margin as little as 1/sixty fourth of an inch or better, relying on the model and setup. For industries in which tight tolerances are important—which include cabinetry or aerospace fabrication—the reduced errors margin of an automatic saw is pretty beneficial.

4. Ease of Measurement and Setup

With a manual saw, the operator wishes to degree, mark, and align each piece earlier than reducing. This will increase the probabilities of mild misalignments or measuring errors. On the other hand, automatic chop saws typically have characteristic virtual interfaces, laser courses, and programmable settings that remove the need for guide measuring. This no longer best saves time but additionally enhances average slicing accuracy.

5. Operator Fatigue and Its Effects on Accuracy

Fatigue plays a good sized function in guide operations. As the day progresses, an operator’s hand strength, recognition, and coordination may lessen, leading to inconsistent cuts. Automatic chop saws dispose of this variable totally. Once installed, they function with the identical precision in the course of the painting's cycle, retaining accuracy without being affected by human obstacles.

6. Complex Angles and Miter Cuts

While guide saws can cut complicated angles, accomplishing ideal miter or bevel cuts calls for first-rate attention and regularly more than one tries. Automatic chop saws frequently come with pre-programmed settings or CNC (Computer Numerical Control) talents, making it less complicated to set and reflect elaborate angles as it should be. This guarantees purifier joints and higher fits, especially in custom or distinctive work.

7. Material Handling and Clamping Stability

Manual sawing can be afflicted by instability if the cloth isn’t properly secured, leading to off-angle cuts or slight slips for the duration of operation. Most automated chop saws are prepared with superior clamping structures that hold the fabric in location with uniform stress, ensuring that each reduction is made underneath the identical situations. This complements each safety and precision.

8. Speed vs. Accuracy Tradeoff

Manual saws regularly require operators to gradual down for correct consequences. Rushing via can cause negative best cuts. With automated chop saws, excessive-velocity slicing doesn’t compromise accuracy because of regulated feed fees and automated preventing points. This makes automated saws not simplest faster however additionally more particular, developing a favorable stability for manufacturing environments.

9. Calibration and Maintenance Differences

To hold accuracy, both manual and automated saws require calibration. However, manual saws rely on the person's judgment for alignment, which may be inconsistent. Automatic chop saws often encompass integrated diagnostic tools and calibration software that offer real-time comments and assist keep constant overall performance. Although it is probably extra complex to keep, the automation simplifies the procedure and improves lengthy-term precision.

10. Learning Curve and Human Influence

Finally, it is critical to not forget the gaining knowledge of curves and users have an effect on. Manual saws require an excessive level of ability to function with consistent accuracy, making them less newbie-pleasant. Automatic chop saws, at the same time as requiring technical understanding for setup, limit user affect once programmed. This means that much less skilled operators can nevertheless reap excessive tiers of precision with the right training and setup.

Conclusion: Why Automatic Chop Saws Lead in Accuracy

When evaluating accuracy between manual saws and automated chop saws, the latter clearly gives an area in maximum situations. With features like virtual measurement structures, programmable cut settings, and regular material clamping, automated saws dispose of tons of the range associated with guide reduction. They offer repeatable, high-precision results best for industries requiring tight tolerances and mass manufacturing.

Additionally, many of these saws include an automatic saw stop mechanism—an critical characteristic for stopping overcuts and making sure genuine measurements. This integrated stopping gadget ensures that each reduce ends exactly in which it ought to, similarly solidifying the automated chop saw as the superior desire in terms of accuracy and reliability.

Whether you are coping with a huge fabrication task or searching for precision in a domestic workshop, making an investment in an automated chop saw can dramatically enhance your output excellent and reduce high-priced mistakes. While guide saws nonetheless have their area for craftsmanship and versatility, the development of the automatic era maintains to set a brand new well known for accuracy in cutting tools.