views

Global Digital Shipyard Industry: Key Statistics and Insights in 2025-2033

Summary:

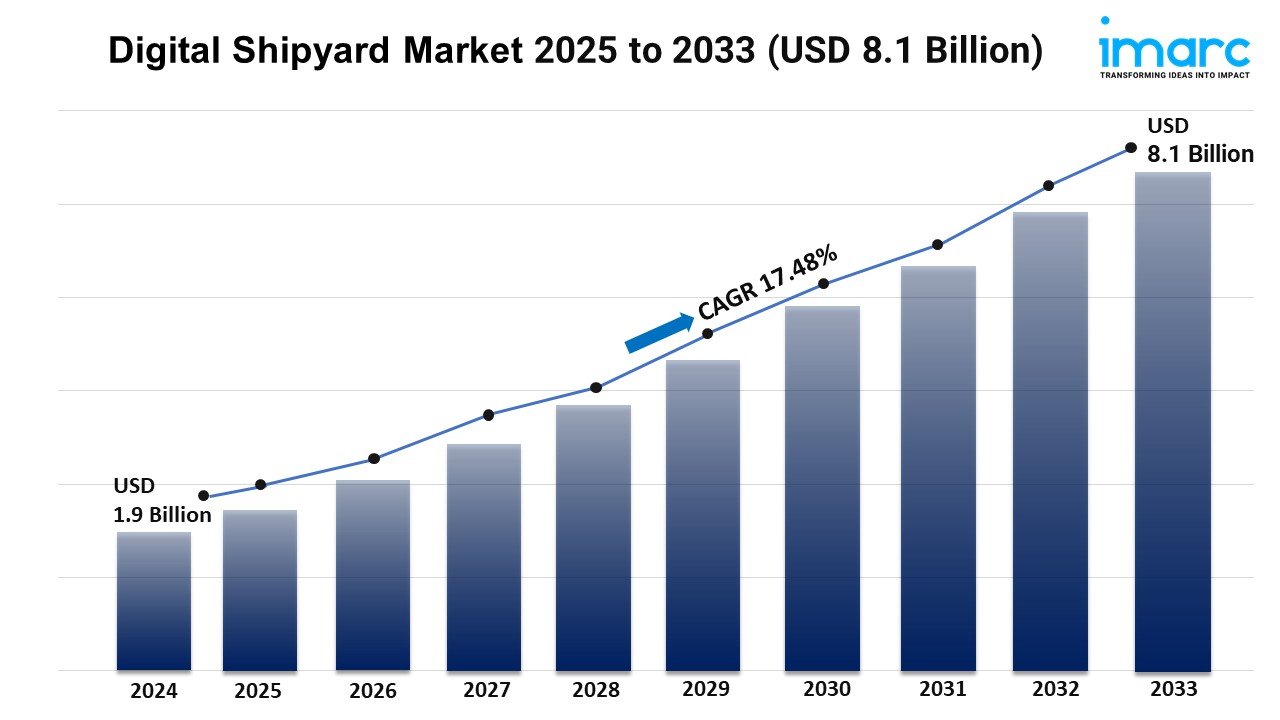

- The global digital shipyard market size reached USD 1.9 Billion in 2024.

- The market is expected to reach USD 8.1 Billion by 2033, exhibiting a growth rate (CAGR) of 17.48% during 2025-2033.

- Asia Pacific leads the market, accounting for the largest digital shipyard market share.

- Commercial shipyards exhibit a clear dominance in the market due to the high demand for new ships and repairs from the booming global trade and shipping industries.

- Artificial intelligence and big data analytics account for the majority of the market share as they enable shipyards to optimize their operations significantly.

- Medium shipyards account for the majority of the market share because they balance the need for high-capacity production with the flexibility to implement digital upgrades.

- The growing adoption of advanced technologies, such as the internet of things (IoT), artificial intelligence (AI), and digital twins, is offering a favorable market outlook.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Grab a sample PDF of this report: https://www.imarcgroup.com/digital-shipyard-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends And Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Industry Trends and Drivers:

- Adoption of Advanced Technologies for Increased Efficiency:

The surge in the implementation of advanced technologies such as IoT, AI, and digital twinning provides good market prospects. These technologies allow the shipyards to increase operational efficiencies, reduce operational costs, ensure real-time monitoring, and perform predictive maintenance of their equipment. IoT sensors provide information about the performance of equipment, and environmental parameters, enabling timely decision-making, limiting downtime, and reducing costs. Digital twins are created to model shipyard operations virtually, helping identify bottlenecks and optimize processes. AI would further help in automating repetitive tasks and improving decision-making through data analytics. This technological convergence facilitates the smooth transition towards smart manufacturing and makes shipyards more agile and responsive to market needs.

- Rising Demand for Sustainable and Green Shipbuilding:

Digital shipyards are in demand owing to increasing emphasis on sustainability and environmental compliance in the maritime industry. Regulations to minimize carbon emissions and improve fuel efficiency are forcing shipbuilders to think and act digitally towards the greening of shipbuilding. Digital shipyards allow the integration of energy-efficient design tools and simulation software for the optimization of ship designs toward lowered environmental impact. The technology promotes the use of lightweight materials, advanced propulsion systems, and eco-friendly coatings that would lead to reduced fuel consumption and emissions. Furthermore, digital shipyards provide the very foundation on which circular economy principles can be implemented by supporting the recycling of materials and components.

- Need for Enhanced Collaboration and Reduced Time to Market

Enhanced collaboration among shareholders and reduced time to market for shipbuilding projects act as catalysts for market growth. It enables shipyards to effectively connect with various departments, suppliers, and customers through integrated digital platforms that facilitate seamless communication and collaboration. Platforms such as these allow sharing data in real-time for well-coordinated efforts in design, engineering, and manufacturing processes, with improvements from reducing errors and rework. 3D modeling, simulation, and virtual reality (VR) act as digital tools with a common visual language that strengthens understanding and coordination in teams. Digital shipyards also mean reduced project lifecycle through better scheduling and resource allocation tools for advanced project management.

Leading Companies Operating in the Global Digital Shipyard Industry:

- AVEVA Group plc (Schneider Electric SE)

- BAE Systems Plc

- Dassault Systemes SE

- IFS AB

- Inmarsat Global Limited (Viasat Inc.)

- Navantia

- Pemamek Oy Ltd.

- Siemens AG

- SSI

- Wärtsilä Oyj Abp

Digital Shipyard Market Report Segmentation:

By Type:

- Military Shipyards

- Commercial Shipyards

Commercial shipyards exhibit a clear dominance in the market due to the high demand for new ships and repairs from the booming global trade and shipping industries.

By Technology:

- AR/VR

- Digital Twin and Simulation

- Addictive Manufacturing

- Artificial Intelligence and Big Data Analytics

- Robotic Process Automation

- Industrial Internet of Things (IIoT)

- Cybersecurity

- Block Chain

- Cloud and Master Data Management

Artificial intelligence and big data analytics account for the majority of the market share as they enable shipyards to optimize their operations significantly.

By Process:

- Research and Development

- Design and Engineering

- Manufacturing and Planning

- Maintenance and Support

- Training and Simulation

Research and development hold the biggest market share owing to its pivotal role in driving innovations and technological advancements within the maritime industry.

By Capacity:

- Large Shipyards

- Small Shipyards

- Medium Shipyards

Medium shipyards account for the majority of the market share because they balance the need for high-capacity production with the flexibility to implement digital upgrades.

By Digitalization Level:

- Fully Digital Shipyard

- Semi Digital Shipyard

- Partially Digital Shipyard

Semi digital shipyard represents the largest segment, as they offer a cost-effective approach to adopting digital tools without the extensive investments required for full digitalization.

By End Use:

- Implementation

- Upgrades and Services

Implementation accounts for the leading market share, which can be attributed to its pivotal role in the transformation of traditional shipbuilding processes into technologically advanced and streamlined operations.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific dominates the market on account of its large shipbuilding industry, significant investments in technology, and strong maritime trade activities.

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

Comments

0 comment