views

In the case of HVAC systems, reliability and efficiency are not buzzwords—they're vital. One of the critical pieces that gets the least amount of credit when it comes to making both possible is the cooling coil. The coils are not the most glamorous part of the system, but their contribution to the success of any air conditioning or refrigeration system is downright vital.

In this guide, we will take apart the functionality of what cooling coils are, the categories that exist, how to select the correct one, and maintenance tips for optimal performance.

What Are Cooling Coils and Why Do They Matter?

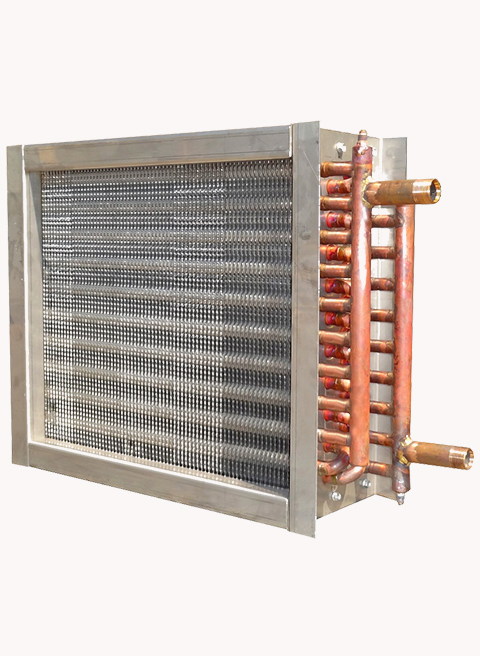

Fundamentally, a cooling coil is a heat exchanger which dehumidifies air by pumping refrigerant or chilled water through a network of metal tubes. As hot air from the surroundings flows over the coil, the heat is transferred to the fluid within, thus cooling the air prior to it being circulated back into the room or space.

Cooling coils have a direct influence on:

Thermal comfort

Energy usage

System life

Indoor air quality

Without a proper coil, even the most sophisticated HVAC installation will be lacking.

Types of Cooling Coils

Selecting the proper cooling coil begins with learning about the various types. These are the most popular ones used in HVAC systems:

1. DX Coils (Direct Expansion Coils)

Refrigerant passes directly through the coil.

Used in split units, packaged units, and rooftop systems.

Characterized by rapid cooling and space-saving design.

2. Chilled Water Coils

Distribute cooled water provided by a central chiller.

Usually located in big commercial or industrial facilities.

Provide accurate temperature control and are more efficient in bigger systems.

3. Evaporator Coils

Usually components of refrigeration systems or split air conditioners.

Tasked to absorb heat and allow phase change of refrigerant.

Performance largely depends on effective refrigerant charge.

4. Custom Coils (AHU, Display Counter, etc.)

Specifically manufactured for certain uses such as air handling units or cold display counters.

Materials and sizes can be optimized for optimal efficiency in specialized configurations.

Materials Make a Difference: Copper, Aluminium, and Beyond

Copper tubing and aluminum fins are used in most cooling coils, a choice for cost vs. thermal conductivity balance. For comparison's sake:

Material Pros Cons

Copper Good heat transfer ability, corrosion-resistant Costs more

Aluminum Light in weight, low cost Slightly lower heat transfer capability

Stainless Steel High durability, corrosion-resistant Expensive, lower conductivity

Some coils are also epoxy-coated or hydrophilic to resist corrosion in harsh environments (e.g., coastal areas or kitchens).

How to Choose the Right Cooling Coil

When selecting a cooling coil, consider the following:

System Type: DX or chilled water? The choice depends on the size, cooling load, and layout of the facility.

Capacity Requirements: Size the coil correctly using cooling load calculations. Oversized or undersized coils reduce efficiency.

Material and Coating: Select on the basis of environmental conditions—humidity, salt, grease, etc.

Airflow Design: Coil face area, fin pitch, and number of rows influence airflow resistance and efficiency.

Maintenance Accessibility: Design to enable frequent cleaning and inspection.

Maintenance Hints for Long-Term Performance

Even the finest coil will not perform at maximum efficiency if ignored. Maintenance is essential:

Clean the coils from time to time to avoid dirt accumulation, which minimizes heat transfer.

Inspect for refrigerant leaks in DX systems.

Flush cooled water coils to avoid scaling and corrosion.

Check fins for bending or damage—this impacts airflow.

Replace filters on a regular basis to minimize dust loading on the coil.

Conclusion: The Right Coil = Peak Performance

Coils are not the most visible component of your HVAC system, but they account for a critical amount of the efficiency and effectiveness of the way it functions. If you're specifying a system for a commercial facility or optimizing an industrial installation, selecting the proper coil—and properly maintaining it—is the key to significant benefits in comfort, cost savings, and system life.

Take the time to choose and maintain your cooling coils. Your HVAC system—and your bill—will appreciate it.

Comments

0 comment