views

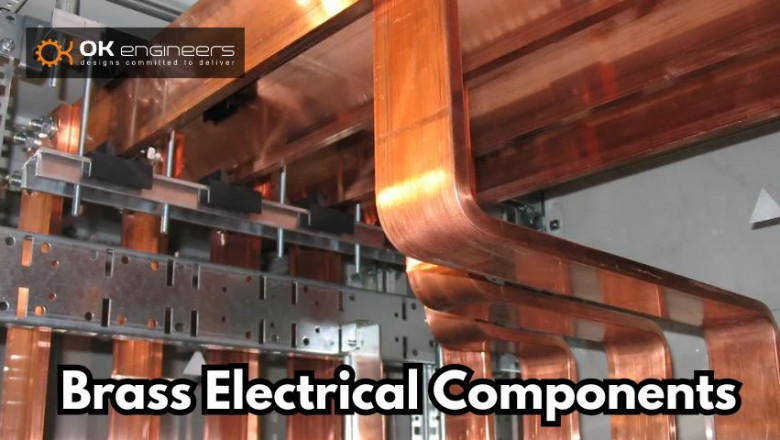

Introduction: In today's fast-paced and technology-driven world, electrical components play a pivotal role in ensuring the efficient operation of various devices and systems. Among the many materials used in manufacturing electrical components, brass stands out due to its excellent properties. Brass electrical components are widely used in industries ranging from electronics to power systems, offering reliability, durability, and corrosion resistance. In this blog, we will explore the significance, applications, and advantages of Brass Electrical Components, with a particular focus on their role in modern industries. We will also highlight the importance of sourcing high-quality brass electrical components from reliable manufacturers like OK Engineers.

What Are Brass Electrical Components? Brass electrical components are made from a blend of copper and zinc, with the addition of other elements that enhance their properties. The resulting material is known for its excellent electrical conductivity, high resistance to corrosion, and strength. These components are designed to facilitate the flow of electricity while ensuring the safety and longevity of electrical systems.

Brass is an ideal material for manufacturing a wide range of electrical components, including connectors, terminals, switchgear, and fittings. Its unique combination of properties makes it an excellent choice for both residential and industrial applications. The versatility of brass allows it to be molded into various shapes and sizes, making it suitable for a diverse range of electrical applications.

Why Choose Brass for Electrical Components? Brass is a popular choice for electrical components due to its numerous advantages:

-

Excellent Conductivity: Brass electrical components offer superior conductivity, which is essential for the efficient transmission of electrical signals. This ensures that electrical systems function smoothly without any power loss or overheating.

-

Corrosion Resistance: One of the standout features of brass electrical components is their high resistance to corrosion. This is particularly important in environments where components are exposed to moisture, heat, or harsh chemicals. Brass components maintain their integrity over time, ensuring the longevity and reliability of electrical systems.

-

Durability: Brass electrical components are known for their durability and strength. They can withstand mechanical stress, making them ideal for applications that require frequent use or harsh environmental conditions.

-

Ease of Molding and Shaping: Brass can be easily molded into various forms, allowing manufacturers to create intricate designs that are both functional and cost-effective. This makes brass an attractive material for producing a wide range of electrical components.

-

Cost-Effective: While brass is not the cheapest material available, it offers a balance of performance and cost that makes it a popular choice for electrical components. Its durability and low maintenance requirements ensure that brass components offer long-term value for money.

Applications of Brass Electrical Components Brass electrical components are used in a wide array of applications across different industries. Below are some of the key areas where brass electrical components play a crucial role:

-

Electrical Connectors: Brass is commonly used to manufacture electrical connectors due to its excellent conductivity and corrosion resistance. These connectors are essential for ensuring secure and reliable electrical connections in a wide range of devices and systems, from household appliances to industrial machinery.

-

Terminals: Brass terminals are widely used in electrical systems to connect wires and cables. These terminals ensure that electrical currents flow efficiently and safely between different components. Brass's corrosion resistance ensures that these terminals remain in optimal condition over time, even in harsh environments.

-

Switchgear and Circuit Breakers: Brass is often used in the manufacturing of switchgear and circuit breakers due to its ability to withstand high temperatures and electrical currents. These components are essential for controlling and protecting electrical circuits, ensuring the safety of electrical systems.

-

Fittings and Enclosures: Brass fittings and enclosures are used to house electrical components and protect them from external factors such as moisture, dust, and physical damage. Brass’s durability and corrosion resistance make it an ideal material for these applications.

-

Electrical Contacts: Brass electrical components are frequently used in the manufacture of electrical contacts, which play a key role in initiating or interrupting the flow of electricity in various devices. These components are essential for ensuring the efficient and reliable operation of electrical equipment.

Benefits of Choosing OK Engineers for Brass Electrical Components When it comes to sourcing brass electrical components, quality and reliability are paramount. OK Engineers, a leading manufacturer of brass components, provides top-notch brass electrical components designed to meet the highest industry standards. By choosing OK Engineers as your supplier, you ensure that your electrical systems are equipped with components that offer excellent performance and durability.

-

High-Quality Materials: OK Engineers uses high-quality brass alloys to manufacture electrical components, ensuring that each product meets rigorous performance standards. This results in components that are both reliable and long-lasting.

-

Custom Solutions: Whether you need standard brass electrical components or custom-made solutions, OK Engineers has the expertise and capability to deliver. Their team works closely with clients to design and produce components that meet specific technical requirements.

-

Precision Manufacturing: At OK Engineers, precision is a top priority. The company employs advanced manufacturing techniques to ensure that every brass electrical component is made with the utmost accuracy, ensuring optimal performance and safety.

-

Timely Delivery: In the fast-paced world of electrical manufacturing, timely delivery is essential. OK Engineers understands the importance of meeting deadlines and ensures that all orders for brass electrical components are delivered on time, every time.

-

Competitive Pricing: While offering high-quality products, OK Engineers remains committed to providing competitive pricing. Their efficient manufacturing processes and economies of scale allow them to offer brass electrical components at affordable rates, making them an ideal choice for businesses seeking value without compromising on quality.

Conclusion Brass electrical components are a critical part of modern electrical systems, offering a combination of excellent conductivity, corrosion resistance, and durability. From connectors and terminals to switchgear and circuit breakers, brass is widely used in various applications to ensure the efficient and safe operation of electrical devices and systems. By choosing high-quality brass electrical components from trusted manufacturers like OK Engineers, you can ensure the long-term reliability and performance of your electrical systems. Whether you are looking for standard components or custom solutions, OK Engineers is the ideal partner for your brass electrical component needs.

Comments

0 comment