views

When we think of an HVAC system, we often picture air conditioners, ducts, or even the thermostat on our wall. But behind the scenes, cooling coils play a pivotal role in delivering the comfort we experience indoors. These components are the unsung heroes of HVAC efficiency, especially in commercial buildings and industrial setups.

In this comprehensive guide, we'll explore what cooling coils are, how they work, and why they’re essential to optimizing HVAC systems.

What Are Cooling Coils?

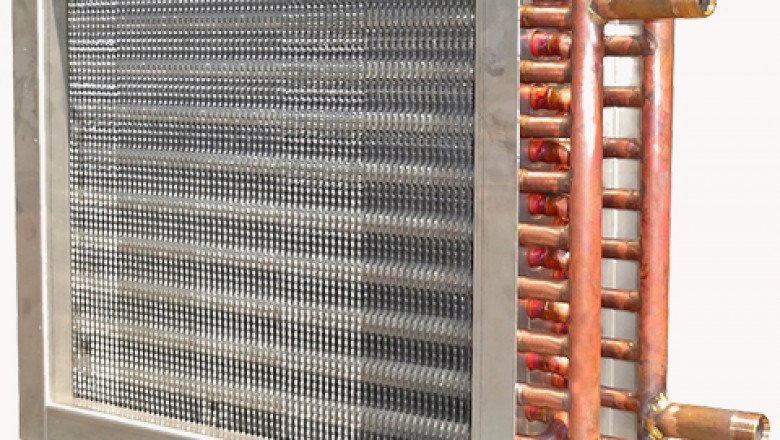

Cooling coils, often located inside Air Handling Units (AHUs) or Fan Coil Units (FCUs), are heat exchangers designed to remove heat from the air passing through them. They typically consist of copper tubes and aluminum fins. As warm air flows over the coil, heat is transferred to the refrigerant or chilled water inside, cooling the air before it circulates through the building.

Types of Cooling Coils

There are mainly two types of cooling coils used in HVAC systems:

1. Direct Expansion (DX) Coils

These use refrigerant directly inside the coil tubes. A compressor, expansion valve, and other refrigeration cycle components regulate the refrigerant.

Best For: Small to medium-sized buildings where a simpler, standalone system is needed.

2. Chilled Water Coils

These circulate chilled water (supplied by a chiller) through the coil. Air passing over these coils is cooled by the chilled water, not direct refrigerant.

Best For: Large commercial buildings with centralized chiller plants.

Why Cooling Coils Matter in HVAC Optimization

1. Energy Efficiency

A well-functioning coil maximizes heat exchange, allowing the system to cool air faster and run for shorter durations. This directly translates to lower energy bills.

2. Air Quality & Comfort

Cooling coils don’t just reduce temperature—they also help in dehumidification. Proper humidity levels improve indoor air quality and make the environment more comfortable.

3. System Longevity

Efficient coils reduce the load on compressors and fans, minimizing wear and tear on the entire HVAC system.

4. Consistent Performance

Clean and properly sized coils maintain even temperature distribution throughout a building, avoiding hot or cold spots.

Common Issues That Affect Coil Performance

- Dirt and Dust Accumulation

Dust acts as an insulator and prevents proper heat exchange. Over time, this can severely degrade performance and efficiency.

- Corrosion

Especially in humid or coastal environments, coils are prone to corrosion. This weakens the metal and can cause leaks.

- Improper Sizing

A coil that's too small won’t cool efficiently; too large, and it may short-cycle, causing humidity problems.

- Refrigerant or Water Flow Issues

Improper flow rate or blockage can hinder the cooling process, even if the coil itself is in good shape.

Best Practices for Coil Maintenance

-

Regular Cleaning: Use coil cleaners or mild detergents to remove dust and debris.

-

Inspect for Corrosion: Apply anti-corrosion coatings if needed.

-

Check Airflow and Filters: Dirty filters can reduce airflow, making coils work harder.

-

Schedule Professional Servicing: At least once a year, have a technician check the coil and entire system performance.

Conclusion

Cooling coils may not be the most visible part of your HVAC system, but they are certainly among the most important. Investing in high-quality coils, ensuring proper installation, and maintaining them regularly can significantly boost your system’s efficiency, reduce costs, and extend its life.

Whether you're an HVAC professional or a facility manager, understanding and optimizing cooling coils is key to achieving better climate control and energy savings.

Comments

0 comment