views

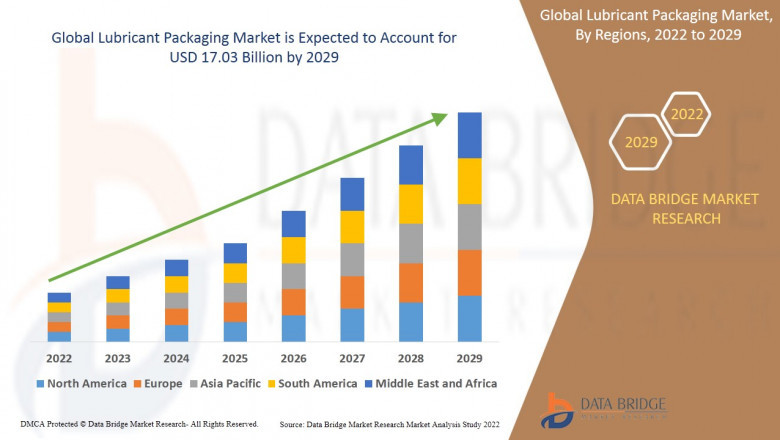

"Global Lubricant Packaging Market - Overview, Size, Share, Industry Trends and Opportunities

Global Lubricant Packaging Market, By Packaging Type (Stand-up Pouches, Bottles, Drums, Pails, Cans, Tubes, Kegs, Bags-in-box, IBC), Material (Metal, Plastic, Others), Lubricant (Engine Oil, Transmission and Hydraulic Fluid, Process Oil, Metal-working Fluid, General Industrial Oil, Gear Oil, Greases), End Use (Automotive, Metal Working, Oil and Gas, Power Generation, Machine Industry, Chemicals, Other Manufacturing)– Industry Trends and Forecast to 2029.

Access Full 350 Pages PDF Report @

https://www.databridgemarketresearch.com/reports/global-lubricant-packaging-market

**Segments**

- **Material Type**: The lubricant packaging market can be segmented by material type into metal, plastic, paperboard, and others. Metal packaging offers durability and high barrier properties, making it suitable for storing lubricants. Plastic packaging is lightweight, cost-effective, and customizable, catering to different packaging needs. Paperboard packaging is eco-friendly and recyclable, appealing to environmentally conscious consumers.

- **Packaging Type**: The market can also be segmented by packaging type, including bottles, cans, drums, pails, and kegs. Bottles are convenient for retail sales and smaller quantities, while cans offer robustness and protection for lubricants during transportation. Drums and pails are ideal for bulk packaging, providing storage efficiency and ease of handling. Kegs are often used for industrial lubricants due to their larger capacity.

- **Lubricant Type**: Another important segmentation is based on the type of lubricants being packaged, such as engine oils, transmission fluids, hydraulic fluids, process oils, and metalworking fluids. Each type of lubricant requires specific packaging considerations to ensure compatibility, durability, and safety during storage and transportation.

- **End-User Industry**: The lubricant packaging market is further segmented by end-user industry, including automotive, industrial, marine, aerospace, and others. Automotive industry demands convenient and secure packaging solutions for lubricants used in vehicles. Industrial sector requires robust packaging for heavy-duty lubricants used in machinery and equipment. Marine and aerospace industries have specific lubrication needs, necessitating specialized packaging solutions.

**Market Players**

- **Amcor plc**: A leading player in the lubricant packaging market, offering a wide range of packaging solutions for various industries. The company focuses on innovative designs and sustainable packaging materials to meet customer demands.

- **Greif, Inc.**: Greif specializes in industrial packaging solutions, including lubricant packaging for bulk and specialty applications. The company provides customizable packaging options to cater to different lubricant types and end-user requirements.

- **Mauser Packaging Solutions**: Mauser is a key player in the packaging industry, offering durable and reliable packaging solutions for lubricants. The company's focus on sustainability and innovation drives its product development in the lubricant packaging segment.

- **Bericap**: Bericap is known for its expertise in closures and caps for packaging solutions, including lubricant containers. The company provides secure closure systems that ensure product integrity and safety during storage and transportation.

The global lubricant packaging market is dynamic, driven by the growing demand for lubricants across various industries. Manufacturers are focusing on innovative packaging solutions that enhance product protection, sustainability, and user convenience. The market players mentioned above are at the forefront of providing advanced packaging options to meet the evolving needs of the lubricant industry.

https://www.databridgemarketresearch.com/reports/global-lubricant-packaging-marketThe global lubricant packaging market is witnessing significant growth driven by various factors such as increasing industrialization, rising automotive production, and growing awareness regarding the importance of proper lubricant storage and transportation. One notable trend in the market is the shift towards sustainable packaging solutions due to heightened environmental concerns and regulatory pressure. Market players are increasingly investing in research and development to introduce eco-friendly materials and designs that reduce the carbon footprint of lubricant packaging.

Moreover, as technological advancements continue to shape the lubricant industry, there is a growing emphasis on packaging solutions that enhance product performance and longevity. This trend is particularly prominent in segments such as metalworking fluids and high-performance engine oils, where the right packaging can significantly impact the efficacy of the lubricants. Market players are leveraging advancements in materials science and packaging technology to develop specialized solutions that meet the stringent requirements of these demanding applications.

Another key aspect influencing the lubricant packaging market is the evolving regulatory landscape governing packaging materials and waste management. Governments around the world are implementing stringent regulations aimed at reducing plastic usage, promoting recycling, and improving overall sustainability practices. Market players are responding to these regulatory changes by introducing packaging solutions that align with the latest sustainability standards and cater to the preferences of environmentally conscious consumers.

Furthermore, the end-user industries driving the demand for lubricants, such as automotive, industrial, marine, and aerospace sectors, are also playing a crucial role in shaping the lubricant packaging market. Each industry has unique requirements in terms of packaging design, material durability, and handling capabilities. Market players need to tailor their packaging solutions to meet the specific needs of these industries, ensuring optimal performance and functionality throughout the product lifecycle.

In conclusion, the global lubricant packaging market is a dynamic and competitive landscape characterized by innovation, sustainability, and industry-specific demands. Market players are under pressure to continually adapt and respond to changing market dynamics, technological advancements, and regulatory requirements. By focusing on developing advanced packaging solutions that prioritize product protection, sustainability, and user convenience, companies can position themselves for success in this rapidly evolving market.**Segments**

Global Lubricant Packaging Market, By Packaging Type (Stand-up Pouches, Bottles, Drums, Pails, Cans, Tubes, Kegs, Bags-in-box, IBC), Material (Metal, Plastic, Others), Lubricant (Engine Oil, Transmission and Hydraulic Fluid, Process Oil, Metal-working Fluid, General Industrial Oil, Gear Oil, Greases), End Use (Automotive, Metal Working, Oil and Gas, Power Generation, Machine Industry, Chemicals, Other Manufacturing) – Industry Trends and Forecast to 2029.

The lubricant packaging market is witnessing robust growth, driven by diverse segments such as material type, packaging type, lubricant type, and end-user industry. The material type segment plays a crucial role in catering to specific needs, with metal packaging offering durability and high barrier properties, plastic packaging offering customization and cost-effectiveness, and paperboard packaging appealing to eco-conscious consumers. Each material type caters to different requirements within the lubricant industry, ensuring the safe storage and transportation of lubricants.

Packaging type segmentation further enhances the market dynamics, with various options such as bottles, cans, drums, pails, and kegs providing tailored solutions for different packaging needs. Bottles are convenient for retail sales, cans offer robust protection during transportation, drums and pails cater to bulk packaging requirements, and kegs serve industrial lubricant needs due to their larger capacity. The packaging type segment reflects the versatility and adaptability of lubricant packaging solutions across different industries and applications.

When considering lubricant type segmentation, it becomes evident that packaging requirements vary depending on the specific type of lubricant being stored or transported. Engine oils, transmission fluids, hydraulic fluids, process oils, and metalworking fluids all have distinct characteristics that influence packaging considerations related to compatibility, durability, and safety. Market players need to tailor their packaging solutions to meet the unique demands of each lubricant type, ensuring the integrity and functionality of the products.

End-user industry segmentation offers valuable insights into the diverse applications of lubricants across sectors such as automotive, industrial, marine, aerospace, and others. Each industry has specific packaging needs that align with their operational requirements, safety standards, and performance expectations. Market players must develop packaging solutions that address the unique challenges within each end-user industry, providing customized options that enhance efficiency, safety, and overall product performance.

In conclusion, the segmentation of the lubricant packaging market into material type, packaging type, lubricant type, and end-user industry highlights the multifaceted nature of this dynamic industry. As market players continue to innovate and adapt to evolving market trends, regulations, and technological advancements, they must focus on developing advanced packaging solutions that meet the diverse needs of customers across various sectors. By prioritizing product protection, sustainability, and user convenience, companies can position themselves for success in the competitive lubricant packaging market and drive industry growth in the coming years.

A high quality Lubricant Packaging market research report is a definitive solution for the success of business at local, regional as well as international level. All the market factors are described in the report as required to define the topic and provide maximum information for better decision making. Several other factors such as import, export, gross margin, price, cost, and consumption are also analyzed under the section of production, supply, sales and market status. An excellent Lubricant Packaging market report comprises of comprehensive and thorough insights which are based on business intelligence.

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Countries Studied:

- North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

- Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

- Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

- Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Core Objective of Lubricant Packaging Market:

Every firm in the Lubricant Packaging Market has objectives but this market research report focus on the crucial objectives, so you can analysis about competition, future market, new products, and informative data that can raise your sales volume exponentially.

- Size of the Lubricant Packaging Market and growth rate factors.

- Important changes in the future Lubricant Packaging Market.

- Top worldwide competitors of the Market.

- Scope and product outlook of Lubricant Packaging Market.

- Developing regions with potential growth in the future.

- Tough Challenges and risk faced in Market.

- Global Lubricant Packaging top manufacturers profile and sales statistics.

Browse Trending Reports:

Lupin Market Size, Share and Trends

Lubricant Packaging Market Size, Share and Trends

Organic Almond Oil Market Size, Share and Trends

Diaper Attachment Sensors Market Size, Share and Trends

Solar Panel Recycling Market Size, Share and Trends

Small Arms Market Size, Share and Trends

Ophthalmic Ultrasound Imaging Systems Market Size, Share and Trends

Oilfield Biocides Market Size, Share and Trends

Serial NOR Flash Market Size, Share and Trends

Automotive Clutch Rotor Market Size, Share and Trends

Chemical Dust Suppressants Market Size, Share and Trends

Sericulture Market Size, Share and Trends

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Comments

0 comment