views

Introduction

The African Continental Free Trade Area (AfCFTA), one of the most ambitious trade agreements in the world, is reshaping the business landscape across the continent. Among the many industries impacted, the Africa Injection Molding Machine Market is experiencing a transformative shift. With AfCFTA now operational, it is removing cross-border tariffs, streamlining regulations, and fostering regional industrialization—laying fertile ground for the expansion of manufacturing sectors, including plastic and polymer processing.

Understanding the AfCFTA and Its Scope

Launched in 2021, the African Continental Free Trade Area brings together 54 of Africa’s 55 countries, creating a market of over 1.4 billion people and a combined GDP exceeding $3 trillion. The agreement aims to:

· Eliminate tariffs on 90% of intra-African goods

· Create a single continental market

· Promote industrial diversification

· Enhance infrastructure development and supply chains

For capital-intensive industries like injection molding, this opens doors to more affordable equipment movement, expanded markets, and increased regional sourcing of raw materials and labor.

Growing Demand for Plastic Products in Africa

The injection molding machine market is directly influenced by the growing demand for plastic products across sectors:

· Packaging: Bottles, containers, and flexible packaging for food and beverages

· Construction: Pipes, panels, and fixtures

· Healthcare: Syringes, medical containers, and PPE components

· Consumer Goods: Household items, automotive parts, electronics casings

Urbanization, rising incomes, and population growth are driving this demand, which is now being met increasingly by local manufacturers due to reduced import dependency under AfCFTA.

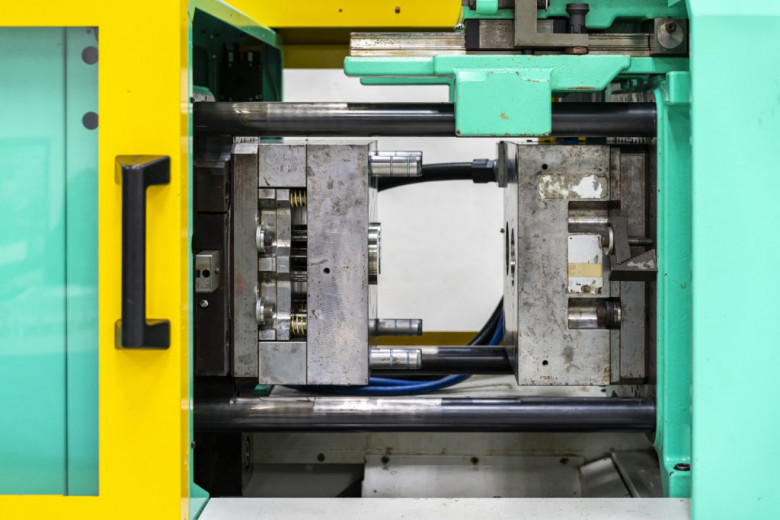

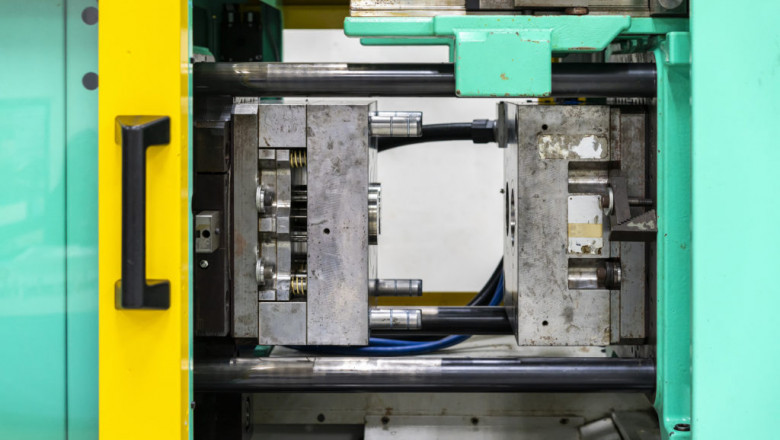

Injection Molding Machines: Enabling Local Manufacturing

Injection molding machines are central to plastic product manufacturing. Their ability to mass-produce complex shapes with consistency and low waste makes them ideal for both small businesses and large-scale factories.

Key machine types in demand in Africa include:

· Hydraulic Injection Molding Machines

· Electric and Hybrid Machines

· Vertical Injection Molding Machines

· Multi-component Injection Machines

With AfCFTA facilitating easier trade of machinery and parts across borders, regional equipment dealers and OEMs are expanding into new markets. Previously isolated countries with underdeveloped manufacturing now have access to competitively priced machines and technical support from neighboring regions.

Key Benefits of AfCFTA for the Injection Molding Machine Market

1. Lower Tariffs on Machinery Imports and Components

Reduced tariffs on industrial goods under AfCFTA make it more affordable for manufacturers to import new or refurbished injection molding machines. This particularly benefits SMEs looking to scale operations in countries like Ghana, Kenya, Nigeria, and Rwanda.

2. Regional Value Chains Development

AfCFTA encourages the development of regional value chains, allowing multiple countries to collaborate in manufacturing processes. For example:

· Raw materials from Nigeria

· Molding in Kenya

· Packaging in Ethiopia

This interdependence is increasing machine sales and service needs across borders.

3. Expansion of Machine Distribution Networks

Machine suppliers and dealers are now establishing satellite offices, showrooms, and service centers in multiple African countries. Brands from Europe and Asia are partnering with local firms to penetrate deeper into the continent.

4. Boost to Local Manufacturing Ecosystems

As more local companies begin producing plastic goods, the need for efficient, affordable, and scalable injection molding machines is rising. AfCFTA’s removal of trade bottlenecks is catalyzing the establishment of new manufacturing hubs.

Challenges Still Impacting the Market

Despite these opportunities, challenges remain:

· Inconsistent Infrastructure: Poor roads and unreliable power supply still affect machine transportation and operations.

· Skills Gap: Shortage of trained machine operators and maintenance technicians in many regions.

· Regulatory Uncertainty: Some countries have yet to fully implement AfCFTA policies, causing temporary confusion and delays.

· Financing Access: Many small businesses struggle to access capital to invest in machinery.

However, regional development banks and international organizations are stepping in with grants, training, and equipment financing programs.

Technological Trends Accelerating Adoption

Several technology trends are shaping the injection molding machine market in Africa:

· Smart Injection Molding Machines: Machines with sensors and AI-driven diagnostics are gaining popularity, especially in export-oriented factories.

· Hybrid Machines: Combining the efficiency of electric with the power of hydraulic systems to suit Africa’s power variability.

· Remote Monitoring and Maintenance: Enabled by IoT platforms, reducing the cost of downtime and technician travel.

· Modular Machine Designs: Allowing flexible, scalable setups for manufacturers with changing product lines.

These advancements align with AfCFTA’s push for modern, competitive industrial systems.

The Road Ahead: Investment and Growth Outlook

With AfCFTA providing a unified trade framework, the injection molding machine market in Africa is poised for:

· Double-digit growth in machine imports and installations over the next 5 years

· Increased FDI from Europe, China, and India in machine manufacturing and assembly plants

· More public-private partnerships to boost industrial training and equipment financing

· Expansion of local machine component manufacturing to reduce reliance on imports

Governments are encouraged to complement AfCFTA policies with energy reforms, tax incentives, and infrastructure development to fully unlock the manufacturing sector’s potential.

Conclusion

The AfCFTA is revolutionizing Africa’s injection molding machine market by opening borders, reducing costs, and encouraging regional industrialization. Countries across the continent are beginning to leverage these new trade freedoms to build stronger local manufacturing capabilities.

By enabling a free flow of machinery, materials, and talent, AfCFTA is turning Africa into a fertile ground for high-efficiency plastic product manufacturing. For machine suppliers, investors, and manufacturers, the time to tap into this transformation is now.

Comments

0 comment