views

Dust Explosion Testing: Understanding the Risks and Precautions 🚨

Dust explosions are a significant hazard in many industries, from manufacturing to agriculture, where combustible dust particles can cause catastrophic damage if ignited. Understanding how to test for dust explosion risks is crucial for ensuring the safety of personnel, facilities, and equipment. This blog post will delve into the basics of dust explosions, the importance of dust explosion testing, the methods used, and how to mitigate the risks associated with combustible dust. 🌪️

What is a Dust Explosion? 💥

A dust explosion is a rapid combustion of fine particles suspended in the air. These particles are usually in a confined space, and when an ignition source is present, they can cause a violent explosion. This can lead to significant property damage, injuries, and even fatalities.

Key Elements for a Dust Explosion

For a dust explosion to occur, three critical elements must be present:

- Combustible Dust: Fine particles, such as wood, coal, grain, or metal dust, that can catch fire.

- Oxygen: Air or other oxidants that fuel combustion.

- Ignition Source: A spark, heat, or any other source of ignition that triggers the explosion.

When all three components meet in a specific environment, the potential for a dust explosion increases dramatically.

Why is Dust Explosion Testing Important? 🧑🔬

Dust explosion testing helps identify potential risks in environments where combustible dust is prevalent. These tests allow for the assessment of the explosion risks and the development of strategies to prevent such accidents.

Benefits of Dust Explosion Testing:

- Prevention of Accidents: By understanding the risk of dust explosions, companies can implement appropriate safety measures.

- Compliance with Safety Standards: Dust explosion testing is crucial for meeting regulations and maintaining workplace safety.

- Protection of People and Property: Proper testing helps minimize the damage to both personnel and property in case of an explosion.

- Better Risk Management: Testing provides data that aids in making informed decisions about ventilation, dust collection, and overall safety measures.

Types of Dust Explosion Testing 🔬

There are several different types of tests and methods used to assess dust explosion risks, including flammability testing, explosibility testing, and ignition sensitivity testing. These tests help identify the potential for dust explosions in different environments.

1. Dust Deflagration Index (Kst) Testing 🧯

The Kst value is a measure of how severe a dust explosion can be. This is determined by testing the speed and pressure of a dust explosion in a controlled environment. The higher the Kst value, the more severe the explosion.

- Kst Range:

- Kst < 200 bar·m/s: Low Explosion Severity

- Kst between 200 and 300 bar·m/s: Medium Explosion Severity

- Kst > 300 bar·m/s: High Explosion Severity

Kst testing helps design appropriate explosion protection systems to limit the impact of such explosions.

2. Minimum Explosible Concentration (MEC) Testing 🔥

The MEC refers to the minimum concentration of dust in the air required to produce an explosion. During MEC testing, dust is suspended in the air, and ignition sources are introduced to determine the concentration at which ignition occurs.

- Key Points to Consider:

- Lower MEC values indicate higher explosion potential.

- Proper dust control measures must be put in place when concentrations approach MEC levels.

3. Ignition Sensitivity Testing ⚡

This test evaluates the sensitivity of dust to various ignition sources, including sparks, flames, and electrical discharges. Understanding how easily a particular dust type can be ignited helps industries to avoid triggering explosions unintentionally.

- Types of Ignition Sources:

- Static electricity

- Hot surfaces

- Sparks from machinery

4. Explosion Pressure Testing 🌋

Explosion pressure testing measures the amount of pressure generated during a dust explosion. This helps determine the structural integrity requirements for buildings and equipment exposed to potential explosions.

- Key Results from Pressure Testing:

- Peak Pressure: The highest pressure reached during the explosion.

- Rate of Pressure Rise: The speed at which pressure increases, giving insight into how quickly the explosion will escalate.

Factors Affecting Dust Explosion Risks ⚙️

Several factors can influence the likelihood and severity of dust explosions. These factors must be carefully controlled in environments where combustible dust is present.

1. Particle Size 🔬

Smaller dust particles have a larger surface area, making them more likely to combust. This is why fine dust, like flour or coal dust, is more dangerous than coarser materials.

2. Dust Shape and Composition 🏭

The physical properties of dust—such as shape, density, and composition—can significantly affect its explosibility. Irregularly shaped particles often have higher surface areas, leading to more violent explosions.

3. Concentration of Dust 🌪️

As mentioned earlier, the concentration of dust in the air plays a crucial role in the occurrence of an explosion. High concentrations increase the chances of ignition, while lower concentrations might not be enough to trigger an explosion.

4. Ventilation and Airflow 💨

Proper ventilation systems can help control dust accumulation and reduce explosion risks. Inadequate ventilation or poor airflow may cause dust to settle in areas where it can easily be disturbed and ignited.

5. Temperature and Humidity 🌡️

The ambient temperature and humidity levels also play a role in dust explosion risks. High temperatures can reduce the dust’s moisture content, making it more combustible. Humid conditions may reduce the dust's explosiveness by preventing it from becoming airborne.

Dust Explosion Prevention Measures 🔒

After testing and identifying the risks, several safety measures can be implemented to prevent dust explosions from occurring.

1. Dust Collection Systems 🧹

Install dust collectors to capture dust particles at their source. These systems can help remove dust from the air before it reaches dangerous concentrations.

- Types of Dust Collection Systems:

- Bag filters

- Cyclone separators

- Wet scrubbers

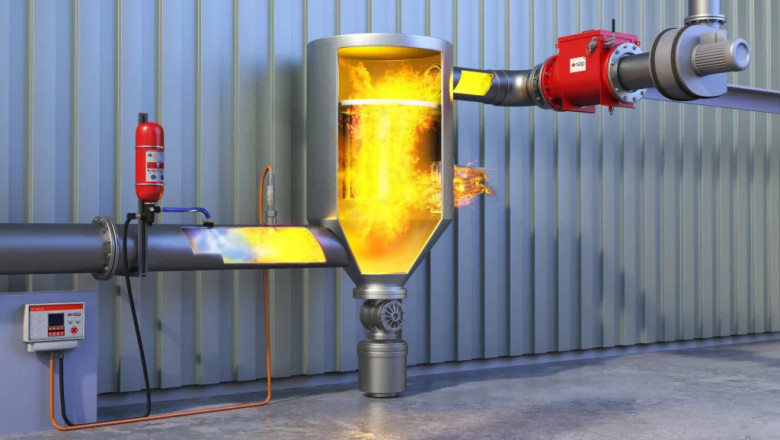

2. Explosion Venting and Suppression 💣

Explosion venting systems allow gases from an explosion to escape in a controlled manner, preventing catastrophic damage. Explosion suppression systems are designed to detect and extinguish explosions before they can escalate.

3. Proper Equipment Maintenance 🛠️

Regular inspection and maintenance of equipment are essential to ensure that machinery does not become an ignition source. This includes checking for faulty electrical wiring, sparks, or hot surfaces that could ignite combustible dust.

4. Training and Awareness 🧑🏫

Employees should be well-trained to understand the risks of dust explosions and how to avoid creating dangerous dust concentrations. Regular safety drills and hazard awareness programs are vital for accident prevention.

Conclusion: Ensuring a Safe Workplace 🛡️

Dust explosions are a real hazard in many industries, but with proper dust explosion testing and preventive measures, they can be minimized. By conducting regular testing and ensuring the right safety protocols are in place, industries can significantly reduce the risk of these dangerous events. Always remember, safety is a priority, and with the right knowledge and precautions, you can protect your employees and facilities from dust explosion disasters. 🌟

Contact Us Today!

Business Address: 21 Ellis Street, London SW1X9AL

Business Phone: +44 208-2438-914

Hours of Operations: 9am til 5pm Monday - Friday

Comments

0 comment