views

Introduction

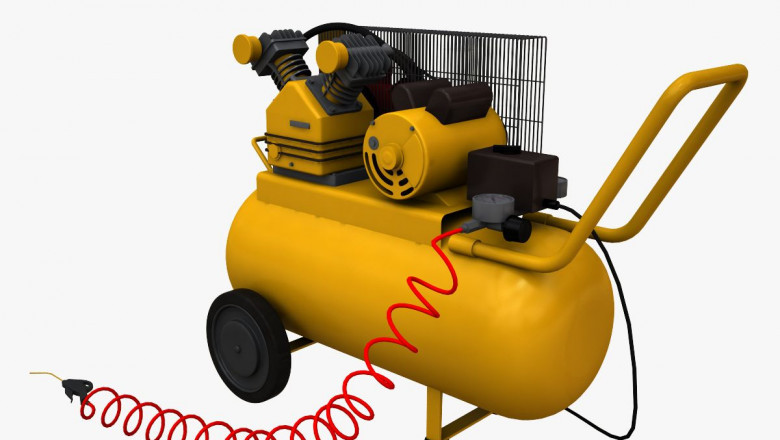

Taiwan Air Compressor Market industrial sector is experiencing rapid transformation. As smart manufacturing becomes the norm rather than the exception, air compressor suppliers are embracing new technologies to meet the rising demands for efficiency, reliability, and sustainability. At the forefront of this shift is the adoption of AI-driven control systems, reshaping how air compressors are managed, maintained, and optimized across factories.

In this article, we’ll explore how artificial intelligence (AI) is revolutionizing Taiwan’s air compressor market, what’s driving its adoption, and why local manufacturers, particularly in the semiconductor, electronics, and precision machinery sectors, are turning to smart compressed air solutions for a competitive edge.

Market Overview: Taiwan’s High-Tech Manufacturing Boom

Taiwan is globally renowned for its semiconductor production, with companies like TSMC, MediaTek, ASE Group, and UMC leading the charge. These operations rely heavily on compressed air systems to power tools, maintain cleanrooms, and operate robotic machinery. In fact:

-

Compressed air accounts for up to 20-30% of total electricity consumption in a typical factory.

-

Poorly managed compressors can result in leaks, pressure loss, and energy waste.

-

Traditional systems lack the responsiveness and insight required for today's real-time, data-driven environments.

This has led to a surge in demand for AI-powered air compressor control systems, designed to enable predictive maintenance, dynamic load balancing, and automated energy optimization.

What Are AI-Driven Air Compressor Control Systems?

AI-driven control systems integrate machine learning algorithms with IoT-connected sensors and software to enable:

-

Real-time monitoring of pressure, temperature, load, and efficiency

-

Adaptive performance tuning based on usage patterns

-

Predictive maintenance alerts to reduce downtime

-

Energy usage analytics for ESG and cost management

-

Remote diagnostics for quick troubleshooting

These systems are typically deployed via:

-

Smart PLCs (Programmable Logic Controllers)

-

Cloud-based analytics platforms

-

Mobile and desktop dashboards for operators

Why Taiwan’s Air Compressor Industry Is Shifting to AI

1. Rising Energy Costs and Sustainability Mandates

Electricity prices in Taiwan are climbing, and factories are under increasing pressure to reduce carbon emissions. AI systems can:

-

Automatically reduce compressor runtime during off-peak periods

-

Identify leaks or overpressurization

-

Suggest efficiency upgrades based on historical data

This helps companies align with Taiwan’s Net-Zero Emissions 2050 roadmap and qualify for green factory certifications like EEWH.

2. Smart Manufacturing (Industry 4.0) Alignment

Taiwan’s Ministry of Economic Affairs has been actively promoting Smart Machinery and Industry 4.0 through funding, subsidies, and training. AI-enabled air compressors:

-

Seamlessly integrate with MES, SCADA, and ERP systems

-

Enhance overall plant automation

-

Reduce the human error associated with manual control

3. Unplanned Downtime = Big Losses

In precision manufacturing, unexpected compressor failure can shut down entire production lines, leading to massive losses. AI control systems enable:

-

Condition-based alerts before a failure happens

-

Predictive replacement schedules for parts like filters, belts, and valves

-

24/7 monitoring without human oversight

This level of reliability is especially critical in semiconductors, food processing, pharma, and electronics assembly.

Real-Life Applications in Taiwanese Industries

Semiconductors (TSMC, UMC)

Semiconductor fabs use oil-free Class 0 air compressors where consistency and reliability are non-negotiable. AI-driven systems:

-

Adjust pressure dynamically across cleanroom zones

-

Ensure redundancy in case of compressor faults

-

Monitor for moisture contamination risks

Biotech and Pharma (Taiwan Biotech Co.)

In sterile environments, AI controllers help maintain precise pressure and flow rate levels while tracking filter health and compliance with GMP standards.

CNC and Precision Machining (Taichung Industrial Zone)

AI software predicts tool wear and load impact on compressors powering pneumatic CNC machines, reducing scrap rates and extending equipment life.

Energy Savings and ROI Potential

Studies show AI-driven systems can reduce compressed air system energy usage by 20–35%. In Taiwanese factories spending millions on electricity annually, this translates to:

-

NT$5 million+ in yearly savings

-

Payback periods of 12–24 months

-

Greater asset uptime and longer service life

Additionally, carbon emissions reductions improve a company’s ESG profile, a growing requirement for international supply chain contracts.

Integration with Other Smart Systems

AI-driven air compressors in Taiwan are increasingly integrated with:

-

Smart HVAC systems for shared energy loads

-

Digital twins to simulate compressor performance

-

Factory-wide energy management platforms

-

Hydrogen or solar-powered microgrids

This connectivity is vital for Taiwan’s Urban Industrial Zones, where vertical factories require space- and energy-efficient infrastructure.

![Smart Mirror Market [New Report] by Updated Development 2033](https://timessquarereporter.com/upload/media/posts/2025-04/15/smart-mirror-market-new-report-by-updated-development-2033_1744709146-s.jpg)

![Gypsum And Drywall Market [2025-2033] is Growing Rapidly at Upcoming](https://timessquarereporter.com/upload/media/posts/2025-04/17/gypsum-and-drywall-market-2025-2033-is-growing-rapidly-at-upcoming_1744883378-s.jpg)

![Construction Software Market [2025-2033] is Growing Rapidly at Upcoming](https://timessquarereporter.com/upload/media/posts/2025-04/15/construction-software-market-2025-2033-is-growing-rapidly-at-upcoming_1744709975-s.jpg)

Comments

0 comment