views

Introduction

The Australia Tactile Sensors Market, a cornerstone of the nation's economy, is constantly seeking innovative solutions to enhance safety, efficiency, and productivity. While automation and advanced analytics have made significant strides, a crucial technology with largely untapped potential is poised to revolutionize operations: tactile sensors. This article delves into the transformative possibilities of integrating tactile sensors within the Australian mining sector, exploring their applications, benefits, and the path towards widespread adoption.

Understanding Tactile Sensors: The Sense of Touch for Machines

Tactile sensors, at their core, mimic the human sense of touch. They are devices capable of detecting and measuring physical contact, pressure, force, vibration, and even texture. Unlike vision-based or proximity sensors that perceive objects from a distance, tactile sensors provide direct, localized information about the interaction between a machine or system and its environment.

These sensors come in various forms, utilizing different sensing technologies such as:

- Resistive: These sensors change electrical resistance in response to applied pressure. They are often cost-effective and suitable for measuring force distribution.

- Capacitive: These sensors detect changes in capacitance caused by deformation under pressure. They offer high sensitivity and are often used in touchscreens and more sophisticated applications.

- Piezoelectric: These sensors generate an electrical charge when subjected to mechanical stress or pressure. They are excellent for detecting dynamic forces and vibrations.

- Optical: These sensors use light to measure deformation or contact area. They can offer high resolution and are suitable for complex surface profiling.

- Ultrasonic: While often used for proximity sensing, specialized ultrasonic tactile sensors can measure surface characteristics and contact forces.

The Australian Mining Landscape: Challenges and Opportunities

The Australian mining industry faces a unique set of challenges, including:

- Harsh and Remote Environments: Mining operations often occur in extreme temperatures, dusty conditions, and geographically isolated locations, demanding robust and reliable equipment.

- Safety Concerns: Ensuring the safety of personnel is paramount, with risks associated with heavy machinery, unstable ground, and hazardous materials.

- Operational Efficiency: Maximizing productivity and minimizing downtime are critical for profitability in a competitive global market.

- Resource Optimization: Extracting resources efficiently and minimizing waste are essential for sustainable mining practices.

- Increasing Automation: The industry is increasingly embracing automation to improve efficiency and safety, creating a need for sophisticated sensing capabilities for robotic systems.

These challenges also present significant opportunities for the integration of advanced technologies like tactile sensors, which can offer solutions that address these specific needs.

The Untapped Potential: Applications of Tactile Sensors in Australian Mining

The integration of tactile sensors holds immense potential across various stages of the mining lifecycle:

1. Exploration and Resource Assessment:

- Soil and Rock Characterization: Tactile sensor arrays mounted on robotic probes or drilling equipment can provide real-time data on soil composition, rock hardness, and texture. This information can aid in identifying potential ore bodies and optimizing drilling strategies.

- Core Sample Analysis: High-resolution tactile sensors can be used to analyze the surface properties of core samples, potentially providing non-destructive methods for identifying mineral content and geological structures.

2. Extraction and Material Handling:

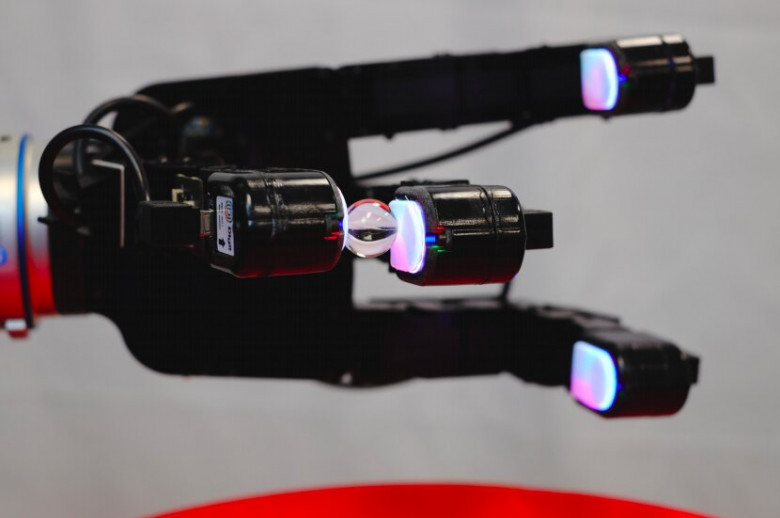

- Robotic Mining Equipment: Integrating tactile sensors into robotic arms and excavators can provide them with a sense of touch, enabling more precise and delicate manipulation of materials. This can improve efficiency in sorting, loading, and unloading tasks, reducing damage to equipment and extracted ore.

- Conveyor Belt Monitoring: Tactile sensor arrays along conveyor belts can detect blockages, tears, or misalignment, enabling proactive maintenance and preventing costly downtime. They can also monitor the load distribution and prevent overloading.

- Crushing and Grinding Optimization: Tactile sensors on grinding mills and crushers can provide real-time feedback on material flow and particle size, allowing for dynamic adjustments to optimize the crushing process and reduce energy consumption.

- Autonomous Haulage Systems (AHS): While primarily relying on GPS and vision, integrating tactile sensors on autonomous trucks can provide an additional layer of safety and awareness. They can detect obstacles in close proximity, monitor tire pressure and wear, and provide feedback on road surface conditions for smoother operation.

3. Maintenance and Equipment Monitoring:

- Predictive Maintenance: Tactile sensors can be used to monitor the vibration, temperature, and pressure distribution in critical machinery like pumps, motors, and bearings. Changes in these tactile signatures can indicate early signs of wear and tear, allowing for proactive maintenance and preventing catastrophic failures.

- Bolt and Fastener Monitoring: In large mining equipment, ensuring the integrity of bolted connections is crucial. Tactile sensors can be integrated into washers or beneath bolt heads to monitor clamping force and detect loosening over time.

- Structural Health Monitoring: Tactile sensor networks can be deployed on large structures like storage silos and processing plants to monitor stress and strain distribution, identifying potential structural weaknesses before they become critical.

- Pipeline Integrity Monitoring: Tactile sensors embedded in pipelines can detect leaks, corrosion, or external damage by sensing changes in pressure or vibration patterns.

4. Safety and Worker Assistance:

- Wearable Tactile Sensors: Integrating tactile sensors into gloves or clothing worn by miners can provide real-time feedback on grip force, exposure to vibrations, or potential contact with hazardous materials.

- Collision Avoidance Systems: Tactile bumpers or sensor arrays on mobile equipment can provide an additional layer of collision avoidance, especially in low-visibility conditions or during close-quarters maneuvering.

- Exoskeletons and Assistive Devices: Tactile sensors in robotic exoskeletons can provide haptic feedback to the wearer, enhancing control and awareness of their movements and interactions with the environment, reducing strain and improving task efficiency.

- Remote Handling of Hazardous Materials: Tactile feedback systems integrated into remotely operated vehicles (ROVs) can allow operators to perform delicate tasks with greater precision and control when handling hazardous substances.

Emerging Innovations and Developments in Tactile Sensor Technology:

The field of tactile sensors is rapidly evolving, with several key innovations making them increasingly suitable for the demanding mining environment:

- Ruggedization and Environmental Sealing: New materials and designs are making tactile sensors more resistant to dust, moisture, extreme temperatures, and mechanical shock – crucial for the Australian mining context.

- Miniaturization and Flexibility: Smaller and more flexible sensors can be integrated into tighter spaces and conform to complex surfaces, expanding their application possibilities.

- Wireless Connectivity: Wireless tactile sensor networks enable easier deployment and data acquisition in remote mining locations.

- Integration with AI and Machine Learning: Combining tactile sensor data with artificial intelligence and machine learning algorithms allows for more sophisticated analysis, pattern recognition, and predictive capabilities. For example, AI can be trained to recognize subtle tactile signatures indicative of equipment failure or unsafe conditions.

- Haptic Feedback Systems: Advanced haptic feedback systems can translate tactile sensor data into realistic sensations for human operators controlling remote equipment, enhancing their dexterity and situational awareness.

- Low Power Consumption: Energy-efficient tactile sensors are essential for long-term deployment in remote locations and for integration into battery-powered devices.

- Advanced Materials: The development of new conductive polymers and nanomaterials is leading to more sensitive, durable, and cost-effective tactile sensors.

Overcoming Barriers to Adoption in the Australian Mining Industry:

Despite the significant potential, the widespread adoption of tactile sensors in the Australian mining industry faces certain hurdles:

- Initial Investment Costs: Implementing new sensor technologies can involve upfront capital expenditure.

- Integration Challenges: Integrating tactile sensors with existing mining equipment and control systems may require significant engineering effort.

- Data Management and Analysis: Processing and interpreting the large volumes of data generated by tactile sensor networks requires robust infrastructure and expertise.

- Lack of Awareness and Expertise: There might be a lack of awareness within the industry about the capabilities and benefits of tactile sensor technology, coupled with a shortage of skilled personnel to implement and maintain these systems.

- Trust and Reliability: Ensuring the long-term reliability and accuracy of tactile sensors in harsh mining environments is crucial for building trust and encouraging adoption.

The Path Forward: Realizing the Untapped Potential

To fully realize the untapped potential of tactile sensors in the Australian mining industry, a multi-faceted approach is needed:

- Increased Research and Development: Continued investment in R&D focused on developing robust, cost-effective, and application-specific tactile sensor solutions for the mining sector is crucial.

- Industry Collaboration: Collaboration between sensor manufacturers, mining companies, research institutions, and government bodies is essential to identify specific needs, develop tailored solutions, and facilitate technology transfer.

- Pilot Projects and Demonstrations: Conducting pilot projects and demonstrating the tangible benefits of tactile sensors in real-world mining environments can help overcome skepticism and encourage wider adoption.

- Education and Training: Raising awareness and providing training to mining personnel on the capabilities, implementation, and maintenance of tactile sensor systems is vital.

- Development of Industry Standards: Establishing industry standards for tactile sensor integration and data exchange can facilitate interoperability and accelerate adoption.

- Government Support and Incentives: Government initiatives and incentives can help offset the initial investment costs and encourage the adoption of innovative technologies like tactile sensors in the mining sector.

Conclusion

Tactile sensors represent a significant, yet largely untapped, opportunity to enhance safety, efficiency, and productivity in the Australian mining industry. By providing machines with a sense of touch, these technologies can revolutionize various aspects of mining operations, from exploration and extraction to maintenance and worker safety. As sensor technology continues to advance and costs decrease, and with a focused effort on overcoming adoption barriers, the Australian mining sector stands to gain immensely from embracing the power of touch. The future of mining in Australia could very well be a more intuitive, safer, and more efficient one, enabled by the integration of sophisticated tactile sensing capabilities.

Comments

0 comment