Industrial Cabineted X-ray Market Dynamics and Insights into Market Developments and Forecast Trends

views

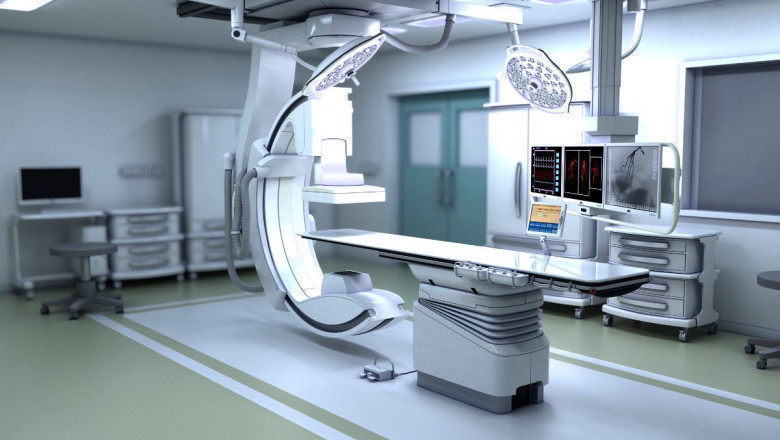

The industrial cabineted X-ray market is experiencing a significant transformation driven by advancements in non-destructive testing (NDT) technologies, heightened demand for quality control, and the integration of artificial intelligence (AI). These systems, primarily used in industries such as aerospace, automotive, electronics, and energy, are critical for ensuring product safety, integrity, and performance. As industries face increasing pressure to adhere to stringent quality and safety standards, industrial cabineted X-ray systems are positioned as indispensable tools for defect detection and materials analysis. This article delves into the market dynamics, highlighting key developments, emerging trends, and the forecast for growth.

Market Dynamics: Growth Drivers and Challenges

-

Technological Advancements in X-ray Systems Technological innovation is a primary driver of growth in the industrial cabineted X-ray market. The incorporation of AI, machine learning, and high-resolution imaging is significantly enhancing the capabilities of X-ray systems. AI integration allows for automated defect detection, real-time image processing, and improved accuracy in identifying micro-defects. Additionally, 3D imaging technology is gaining traction as it provides deeper insights into complex structures, enabling more accurate inspections of intricate materials. These technological advancements are pushing the boundaries of traditional X-ray systems, making them more efficient and versatile across various industries.

-

Increasing Demand for Non-destructive Testing (NDT) The increasing emphasis on quality control, regulatory compliance, and product safety is fueling the demand for non-destructive testing (NDT) methods, particularly in critical industries like aerospace, automotive, and electronics. As manufacturers seek to reduce waste, minimize defects, and ensure the reliability of their products, industrial X-ray systems offer a cost-effective and reliable solution for internal inspection. Moreover, the shift towards smaller, more lightweight components in industries such as automotive and aerospace increases the need for high-precision X-ray inspection to detect micro-cracks and defects that could compromise structural integrity.

-

Sustainability and Energy Efficiency Environmental concerns and the need for energy-efficient solutions are accelerating the adoption of more sustainable industrial X-ray systems. Companies are developing products that reduce power consumption, minimize radiation exposure, and use eco-friendly materials in their construction. Sustainability is becoming a key competitive differentiator, especially as regulations and industry standards evolve to emphasize environmental responsibility. X-ray system manufacturers that prioritize energy efficiency and green technologies are better positioned to meet the growing demand for sustainable solutions across industries.

-

Challenges: High Costs and Integration Complexity While the demand for advanced industrial X-ray systems is growing, there are several challenges that could hinder market expansion. One of the major barriers is the high upfront cost of acquiring and integrating these systems into existing manufacturing workflows. For small and medium-sized enterprises (SMEs), the financial investment required for high-tech X-ray equipment may be prohibitive. Additionally, integrating these sophisticated systems with legacy production lines can be complex and time-consuming, requiring specialized skills and adjustments to existing processes.

-

Skill Shortages and Training Needs As industrial cabineted X-ray systems become more advanced, the need for skilled operators and technicians to manage these systems grows. The adoption of AI and machine learning in X-ray systems requires a new set of skills, which can be difficult to source in a competitive job market. Companies must invest in extensive training programs to ensure that personnel are proficient in operating the equipment and interpreting the results accurately. The shortage of trained professionals is a growing concern, and addressing this gap will be critical for ensuring the effective use of advanced X-ray systems.

Forecast Trends: Opportunities for Growth

-

Emerging Markets The industrial cabineted X-ray market is expected to experience significant growth in emerging markets, particularly in regions like Asia-Pacific, Latin America, and the Middle East. These regions are witnessing rapid industrialization, an expanding manufacturing base, and increasing demand for quality inspection technologies. As these markets modernize their production capabilities, the need for advanced non-destructive testing solutions will rise, presenting a major growth opportunity for X-ray manufacturers. Companies that can tailor their products to meet the specific needs of these regions will be well-positioned to capitalize on this growing demand.

-

Integration of Automation and AI Automation and AI are expected to be game-changers in the industrial cabineted X-ray market. As machine learning algorithms continue to evolve, the ability to automate defect detection and image analysis will reduce the reliance on human intervention and increase the speed and accuracy of inspections. The automation of routine tasks will also streamline workflows and reduce operational costs, making X-ray systems more accessible to a wider range of industries. As AI-powered X-ray systems become more common, their ability to predict potential failures and provide actionable insights will further enhance their value proposition.

-

Customization and Flexibility The demand for customizable and flexible X-ray systems is expected to increase as industries seek solutions tailored to their unique inspection requirements. Manufacturers are increasingly offering modular X-ray systems that can be adapted to different inspection needs, materials, and component sizes. This flexibility allows companies to invest in systems that meet their specific requirements without incurring unnecessary costs for features they do not need. Additionally, portable and mobile X-ray systems are gaining popularity for on-site inspections in industries like construction and field services, where traditional fixed systems may not be practical.

-

Advanced 3D Imaging and High-Resolution Systems The ongoing development of advanced 3D imaging and high-resolution X-ray systems will further drive market growth. These systems are particularly important in industries where detailed internal analysis is required, such as aerospace, electronics, and automotive. 3D imaging provides a more comprehensive view of complex components, allowing for the detection of even the smallest defects that might not be visible with traditional 2D X-ray systems. As the demand for precision and accuracy in inspections grows, the adoption of high-resolution and 3D X-ray systems is expected to increase.

Conclusion

The industrial cabineted X-ray market is poised for continued growth, driven by technological advancements, rising demand for quality control, and the push for sustainability. While challenges such as high costs, integration complexity, and skill shortages remain, the market is being propelled by key trends such as the integration of AI, the rise of emerging markets, and the development of customizable, high-resolution X-ray systems. As industries continue to seek innovative solutions for non-destructive testing and inspection, the future of the industrial cabineted X-ray market looks promising, offering significant opportunities for companies that can adapt to changing market dynamics and customer demands.

Comments

0 comment