views

The electrically conductive adhesives market is undergoing rapid transformation, driven by evolving technology demands and growing industry applications. As electronic systems become smaller, smarter, and more energy-efficient, traditional joining techniques like soldering are giving way to advanced adhesive solutions. Electrically conductive adhesives (ECAs) offer both electrical and mechanical connectivity, making them critical in manufacturing modern devices. This market intelligence review delves into the key trends, competitive strategies, technological innovations, and regional growth shaping the global ECA landscape.

Strategic Role of Electrically Conductive Adhesives

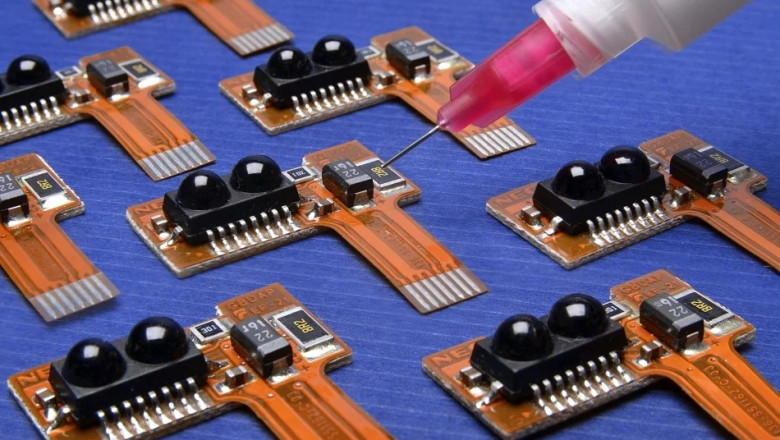

Electrically conductive adhesives are engineered to bond components while facilitating the flow of electricity. They typically consist of a polymer matrix filled with conductive materials such as silver, carbon, or graphite. ECAs are widely used in applications where precision, flexibility, and heat sensitivity are paramount. Industries such as electronics, automotive, aerospace, healthcare, and renewable energy are increasingly integrating ECAs into their production lines.

In electronics, ECAs are indispensable for assembling miniaturized devices, printed circuit boards, and microchips. Their ability to maintain conductivity while withstanding mechanical stress makes them ideal for dynamic environments. In the automotive sector, ECAs are critical in electric vehicle (EV) battery assembly, sensors, and infotainment systems. Their lightweight nature also supports the industry’s focus on energy efficiency and reduced emissions.

Market Dynamics and Emerging Trends

Current market intelligence reveals several macro and micro-level factors influencing ECA demand. First and foremost, the miniaturization of devices is a consistent growth catalyst. As electronics shrink in size but increase in complexity, ECAs offer reliable solutions where soldering fails to deliver due to heat sensitivity or space constraints.

Environmental regulations and sustainability goals are also playing a pivotal role. ECAs are a viable alternative to lead-based soldering, aligning with RoHS and other environmental directives. Manufacturers are actively seeking lead-free, low-VOC, and halogen-free formulations to reduce ecological impact without sacrificing performance.

Another emerging trend is the adoption of ECAs in flexible and wearable electronics. These applications require adhesives that can stretch, bend, and still maintain conductivity. Market leaders are investing heavily in R&D to develop next-generation materials that can meet these demands.

Technological Advancements Fueling Innovation

The integration of nanomaterials into ECAs has been a game-changer. Silver nanoparticles, carbon nanotubes, and graphene are being explored for their superior conductivity and mechanical strength. These materials enhance the adhesive's overall performance, making them suitable for high-frequency and high-temperature applications.

Curing technologies are also evolving. Traditionally, ECAs required heat curing, but newer formulations offer UV, moisture, or room-temperature curing. These alternatives allow for faster production cycles and compatibility with heat-sensitive components.

In addition, hybrid adhesives—combining the benefits of isotropic and anisotropic conduction—are gaining popularity. These versatile products open up new design possibilities in multi-functional devices where both directional and all-around conductivity are needed.

Competitive Landscape and Strategic Moves

The electrically conductive adhesives market is characterized by intense competition among global and regional players. Leading companies are pursuing innovation, partnerships, and geographic expansion to strengthen their market positions. Product differentiation is largely based on adhesive performance, curing speed, conductivity levels, and environmental safety.

Strategic collaborations with electronics manufacturers, EV companies, and renewable energy firms are helping adhesive producers co-develop application-specific products. In parallel, acquisitions and mergers are enabling companies to broaden their technology portfolio and enter new regional markets more efficiently.

Pricing remains a sensitive factor, particularly due to the high cost of conductive fillers like silver. Consequently, there's a rising focus on balancing cost-efficiency with performance by optimizing filler content and exploring alternative materials.

Regional Insights and Growth Opportunities

Asia-Pacific leads the electrically conductive adhesives market, supported by strong manufacturing ecosystems in China, Japan, and South Korea. These countries have robust electronics and semiconductor industries, creating a steady demand for ECAs. Additionally, government incentives for electric vehicles and renewable energy adoption further boost the market.

North America is a significant contributor, with advanced R&D infrastructure and a strong focus on innovation in automotive and aerospace sectors. Europe follows closely, with a commitment to green technologies and smart manufacturing solutions driving adoption.

Emerging markets in Latin America and the Middle East are gradually embracing ECAs, particularly in solar panel production and smart infrastructure. These regions offer untapped potential as industrialization and technological modernization continue.

Future Outlook and Strategic Recommendations

Looking forward, the electrically conductive adhesives market is expected to witness sustained growth as electronics become more integral to daily life. With the rise of 5G, autonomous vehicles, smart cities, and renewable energy, demand for reliable conductive bonding solutions will continue to expand.

Companies aiming to capitalize on this growth should invest in sustainable formulations, smart manufacturing technologies, and strategic partnerships with OEMs and component manufacturers. Staying ahead of regulatory trends and material innovations will be key to maintaining competitive advantage.

Conclusion

This electrically conductive adhesives market intelligence reveals a landscape rich with innovation, opportunity, and strategic evolution. As industries pursue smaller, smarter, and greener solutions, ECAs are becoming essential to modern manufacturing. Forward-thinking companies that adapt to market trends, customer demands, and environmental standards will lead the way in this transformative space.

Comments

0 comment