views

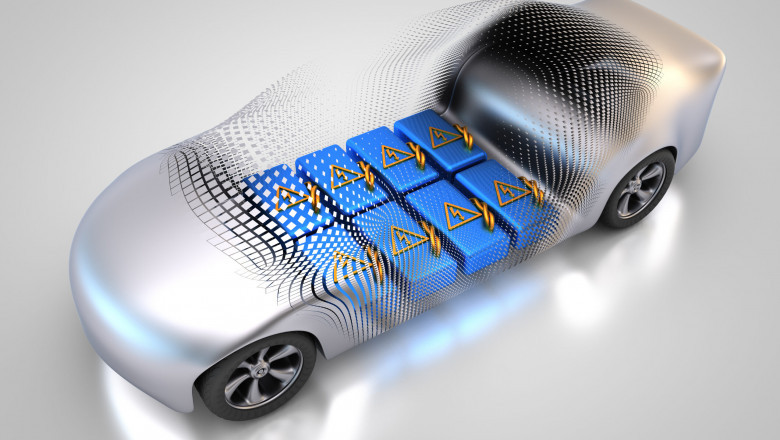

The electric vehicle battery adhesive market has shown significant promise as the world accelerates towards a more sustainable and electrified future. As the adoption of electric vehicles (EVs) increases globally, the need for specialized battery adhesives has become crucial for maintaining the performance, safety, and longevity of EV battery packs. This market is positioned for substantial growth, driven by various technological advancements, regulatory shifts, and the evolving demands of the automotive industry.

-

Increasing Demand for EVs

The global shift towards electric mobility is a major driver for the electric vehicle battery adhesive market. With countries and cities setting ambitious targets for EV adoption, the automotive sector is undergoing rapid transformation. As EV sales continue to grow, the demand for specialized adhesives to ensure the safe and efficient operation of battery systems is expected to rise. The push for greener transportation options, along with increasing consumer awareness about environmental impact, ensures long-term market potential for battery adhesives. -

Advancements in Battery Technology

The development of new, high-performance battery technologies presents significant opportunities for the electric vehicle battery adhesive market. As manufacturers develop lighter, more energy-dense, and longer-lasting batteries, adhesives are required to meet these new performance standards. Solid-state batteries and lithium-sulfur batteries are examples of next-generation battery technologies that demand adhesives with higher thermal resistance, enhanced electrical insulation, and improved structural integrity. This ongoing innovation in battery chemistry creates a growing market for advanced adhesives that can meet these demands. -

Growth of Electric Commercial Vehicles

While passenger electric vehicles dominate the market, electric commercial vehicles are increasingly gaining traction. With the rise of electric trucks, buses, and delivery vans, there is a corresponding need for high-performance battery adhesives that can withstand the greater mechanical stresses and higher energy demands these vehicles require. As commercial fleets transition to electric power, the demand for robust adhesives for larger and more complex battery systems will drive substantial market expansion. -

Stringent Safety Regulations and Standards

As the EV market grows, so too does the need for ensuring safety in battery management. The stringent safety standards enforced by various regulatory bodies worldwide require manufacturers to use adhesives that can resist extreme temperatures, mechanical stresses, and environmental hazards. Adhesives are not only used for bonding components but also play a key role in providing thermal management, electrical insulation, and impact resistance. This growing emphasis on safety ensures a sustained demand for advanced adhesives in the EV battery sector. -

Government Incentives and Policies

Governments around the world are offering incentives, tax rebates, and other policy measures to promote the adoption of electric vehicles. These policies have led to increased investments in the EV infrastructure, battery development, and ancillary products such as adhesives. Subsidies for EV manufacturers often include provisions for materials that enhance vehicle performance and safety. Consequently, favorable government policies will continue to drive the growth of the electric vehicle battery adhesive market by ensuring a stable demand for these products. -

Focus on Lightweight Materials

As automakers strive to improve the range and efficiency of electric vehicles, reducing vehicle weight has become a critical objective. Lightweight adhesives provide an efficient solution by replacing heavier mechanical fasteners while maintaining the structural integrity of battery packs. As the industry continues to innovate, the market for lightweight, high-strength adhesives that can perform in demanding conditions is expanding, further strengthening the market potential for battery adhesives. -

Regional Growth and Global Expansion

The electric vehicle battery adhesive market is witnessing robust growth in key regions such as Asia-Pacific, North America, and Europe. Asia-Pacific, particularly China, Japan, and South Korea, is a hub for EV manufacturing and battery production, driving a significant portion of the demand for battery adhesives. In Europe, stringent environmental regulations and government incentives for electric vehicle adoption are creating opportunities for market expansion. North America is also experiencing growth due to increased investments in EV infrastructure and automotive manufacturing. As the EV market becomes more globalized, the electric vehicle battery adhesive market is expanding its footprint across various regions. -

Emerging Markets in Developing Countries

While the adoption of electric vehicles has been most prominent in developed markets, emerging economies are also catching up. Governments in developing countries are beginning to invest in EV adoption, driven by the need to reduce air pollution and dependency on fossil fuels. As these markets grow, the demand for EVs—and consequently, the need for electric vehicle battery adhesives—will increase. This opens up new opportunities for adhesive manufacturers to enter untapped markets and provide solutions tailored to the specific needs of these regions. -

Sustainability and Eco-Friendly Products

Sustainability has become a significant factor in the development of electric vehicle battery adhesives. As the automotive industry shifts toward more environmentally friendly practices, adhesive manufacturers are developing eco-friendly products that reduce environmental impact. Water-based adhesives, recyclable materials, and non-toxic formulations are gaining popularity among manufacturers seeking to meet sustainability goals. This focus on eco-friendly solutions creates an additional avenue for growth in the market. -

Key Players and Market Competition

The electric vehicle battery adhesive market is competitive, with a range of companies vying for market share. Leading players such as Henkel AG, 3M, and Sika AG are investing in research and development to create adhesives that cater to the evolving needs of the electric vehicle industry. Partnerships between adhesive manufacturers and EV producers are helping to accelerate innovation and create customized solutions. The competition among these players further drives innovation and strengthens the market potential for battery adhesives.

Comments

0 comment