views

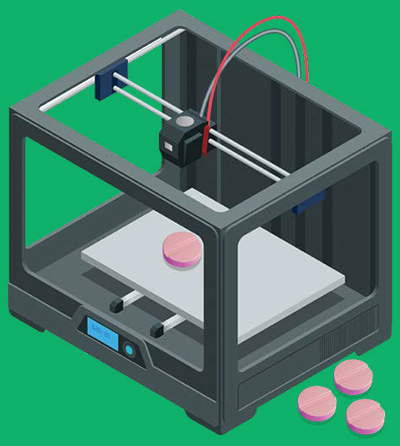

Revolutionizing Drug Manufacturing with 3D Printing

Pharmaceutical 3D printing is a pioneering force in pharmaceutical engineering driving innovation, reshaping pharmaceutics from personalised medicine to clinical trial workflows. Providing a comprehensive overview, this article offers insight into 3D printing as a pharmaceutical manufacturing tool and explores its transformative impact in the field.

Introduction to Pharmaceutical 3D Printing

Three-dimensional (3D) printing is an advanced additive manufacturing technique that constructs complex products by layering materials according to a computer-aided design (CAD) 3D model. 3D printing has marked a transformative paradigm shift in the healthcare sector since the 1990s, where it has played a crucial role in the fabrication of custom dental implants and personalised prosthetics, a development that even surprised innovator Charles Hull, cofounder of the pioneering company 3D Systems (1). 3D printing has also seen significant traction in tissue engineering research, enabling the creation of complex structures using innovative biomaterials to mimic natural tissues. The pharmaceutical sector witnessed the emergence of pharmaceutical 3D printing in the early 2010s, driven by pioneering academics striving to revolutionise medication forms to align with intricate and personalised patient needs (2). Its disruptive nature for pharmaceutical manufacturing holds immense promise for healthcare, poised to fundamentally transform the pharmaceutical industry.

Personalised Medicine and Automated Compounding

3D printing exploded as a manufacturing technique due to its ability to create bespoke objects with unparalleled precision and customisation. Unlike conventional methods, pharmaceutical 3D printing excels in creating complex drug-containing structures and combining multiple drugs into a single pill, unlocking new possibilities in drug development and advanced healthcare that caters to the unique needs of individual patients.

The current method to prepare personalised and non-commercially available prescriptions, pharmaceutical compounding, involves some-what old-fashioned and imprecise techniques, including the breaking of tablets by hand and weighing powders to hand-fill capsules. This not only creates risk but restricts personalised medicine to specific treatments and fewer pharmacies. Pharmaceutical 3D printing automates this process while offering more personalisation options such as shape, colour, flavour and drug combinations (polypills) to increase treatment adherence. Automation reduces specialist workload and human error, making compounding more accessible and easier to implement. With increasing stakeholder investment, this unlocks personalisation for more treatment pathways, moving away from conventional “one-size-fits-all” doses and towards truly personalised medicine. As such, 3D printing paves the way for a new era in personalised medicine, where treatments are prepared to meet the distinct needs of each patient (3, 4, 5). Imagine a world where a person with polypharmacy can take one multi-drug chewable polypill with a personalised dose rather than five different large capsules with a colour and flavour that suits their particular preferences.

Pharma-ink refers to the feedstock formulation that includes excipients and drugs to be printed and is used to print tablets, or printlets (6). There are multiple 3D printing technologies fit for precision medicine, each using different pharma-ink forms. Semi-solid extrusion (SSE) is the most common technique being used by stakeholders. Pharmacists are able to use pastes or gels to print at room temperature, immediate-release tablets, chewable tablets, or fast-disintegrating tablets. Fused deposition modelling (FDM), the most well-known technique, is also being investigated for use, with researchers developing filaments that are deposited with melting, useful for improving drug bioavailability and complex release profiles. Finally, direct powder extrusion (DPE) was developed as an alternative to FDM. Essentially a mini hot melt extruder, DPE offers the same benefits as FDM while avoiding the difficulties with filament pharma-ink development as it prints straight from powder. The University Medical Center Hamburg-Eppendorf has described the successful development and analysis of Levodopa printlets with rapid dissolution, printed using DPE. In addition, they evaluated the integration of machine-learning-assisted medicine 3D printing into their hospital’s workflows (7, 8). An exciting step forward in the field.

Read more: https://www.pharmafocusamerica.com/manufacturing/revolutionizing-drug-manufacturing-with-3d-printing

Comments

0 comment