views

Pharmaceutical Water Market Overview

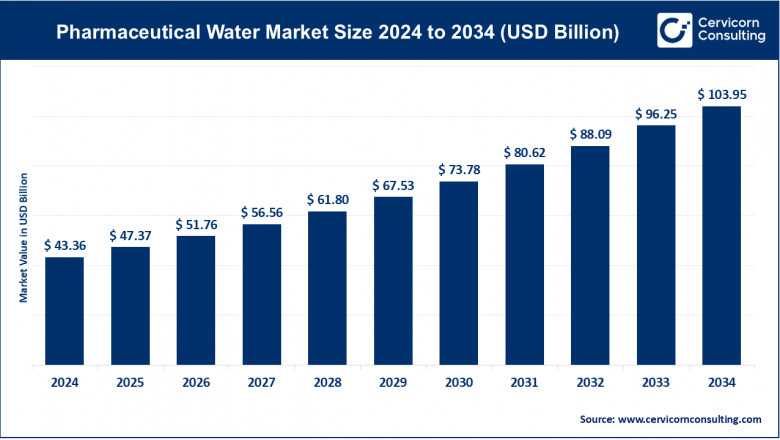

The pharmaceutical water market was valued at USD 43.36 billion in 2024, rising to USD 103.95 billion by 2034 and is expected to grow at a compound annual growth rate (CAGR) of 9.26% from 2025 to 2034.

The pharmaceutical water market plays a crucial role in the pharmaceutical industry, serving as a key ingredient in the production of medicines, as well as in cleaning, sterilizing, and other critical applications. Water, being the most widely used solvent in pharmaceuticals, is required for the preparation of oral solutions, injections, and a wide range of pharmaceutical products. As the demand for pharmaceutical products rises globally, the need for high-quality pharmaceutical-grade water has become paramount. The water utilized in pharmaceutical manufacturing must meet strict regulatory standards to ensure product safety, consistency, and quality.

Pharmaceutical water is classified into various types based on its purity and intended application. These include:

- Purified Water (PW): Typically used in the manufacture of oral formulations, syrups, and non-parenteral preparations.

- Water for Injection (WFI): This is the highest grade of water used in the preparation of parenteral (injection) products.

- Sterile Water for Injection (SWFI): Water that is both sterile and used for injection purposes, with special sterilization protocols.

- Highly Purified Water (HPW): Used in some pharmaceutical processes where WFI is not required but high purity is necessary.

- Buffered Water: Often used for specific pharmaceutical formulations that require a controlled pH level.

The pharmaceutical water market is influenced by factors such as the rising demand for injectable drugs, increased pharmaceutical production, stringent regulatory requirements, and technological advancements in water purification systems.

Get a Free Sample: https://www.cervicornconsulting.com/sample/2348

Market Dynamics

The pharmaceutical water market is driven by various dynamics, each contributing to the growth of the sector. These can be categorized into several key factors:

1. Increasing Demand for Biopharmaceuticals

The rise in the production of biopharmaceuticals, including monoclonal antibodies, vaccines, and gene therapies, has led to an increased requirement for high-quality pharmaceutical water. These drugs often require water with a higher degree of purity, such as WFI or HPW, to meet the stringent standards for bioprocessing and sterile manufacturing.

2. Growing Global Pharmaceutical Market

The global pharmaceutical market has been growing due to the increasing prevalence of chronic diseases, the aging population, and expanding healthcare access in emerging economies. As pharmaceutical production ramps up to meet this demand, there is a corresponding increase in the need for pharmaceutical-grade water for drug formulation, production, and cleaning processes.

3. Strict Regulatory Standards

Regulatory bodies such as the U.S. Food and Drug Administration (FDA), the European Medicines Agency (EMA), and the World Health Organization (WHO) impose stringent standards on water quality in pharmaceutical manufacturing. This includes parameters such as microbial limits, endotoxin levels, and chemical composition, which ensures that pharmaceutical products are safe for consumption or injection. The implementation of Good Manufacturing Practices (GMP) requires facilities to use water that meets these high standards, further driving demand for specialized water treatment systems.

4. Technological Advancements in Water Purification

Technological advancements in water purification systems are a key driver for the pharmaceutical water market. The development of advanced filtration technologies, such as reverse osmosis, ultrafiltration, and distillation, has significantly improved the quality of pharmaceutical water. These technologies help remove impurities, endotoxins, and microorganisms, ensuring that the water used in drug manufacturing meets regulatory standards. Additionally, the use of real-time monitoring systems for water quality has enhanced the efficiency of pharmaceutical production.

5. Environmental and Sustainability Concerns

As environmental concerns and water scarcity become more prominent globally, pharmaceutical companies are increasingly adopting sustainable water management practices. This includes the use of water recycling and reuse technologies in manufacturing processes. By optimizing water use, pharmaceutical companies can reduce their environmental impact while also lowering operational costs.

Key Use Cases of AI in the Pharmaceutical Water Market

Artificial Intelligence (AI) is transforming various aspects of the pharmaceutical industry, including the management and purification of pharmaceutical water. Some key use cases of AI in this market include:

1. Water Quality Monitoring and Predictive Maintenance

AI-based systems can monitor the quality of pharmaceutical water in real time, ensuring that it meets the required standards. Using machine learning algorithms, these systems can predict potential issues, such as bacterial contamination, scaling, or membrane fouling in water filtration systems. By predicting when maintenance or system adjustments are needed, AI can prevent costly downtime and ensure continuous, high-quality water supply.

2. Optimization of Water Purification Processes

AI can optimize water purification processes by analyzing historical data and adjusting parameters such as flow rate, pressure, and temperature in real time. This helps achieve the desired water quality with greater efficiency, reducing energy consumption and minimizing waste. AI can also be used to optimize the operation of reverse osmosis systems, ensuring that they operate at peak performance while meeting regulatory standards.

3. Regulatory Compliance Automation

AI can assist pharmaceutical companies in ensuring compliance with regulatory standards by automating the documentation and reporting processes related to water quality. By continuously tracking key water quality parameters and generating reports, AI can simplify the compliance process, reduce human error, and provide audit trails for regulatory inspections.

4. Resource Optimization

AI technologies can help pharmaceutical companies optimize their water resources by analyzing water usage patterns and suggesting ways to minimize consumption. This is especially valuable in regions facing water scarcity, where pharmaceutical companies need to operate more sustainably. AI can help optimize water recycling, reuse, and waste management processes, contributing to the company's environmental sustainability goals.

Market Trends and Impacts

The pharmaceutical water market is evolving, with several key trends shaping the future of the industry:

1. Increased Demand for Sterile Water and High Purity Water

With the rise of injectable drugs and biologics, there is an increased demand for sterile water for injection (SWFI) and water for injection (WFI). These products require the highest levels of purification, making the production of pharmaceutical water more complex and costly. As biopharmaceuticals become more prevalent, the demand for these types of water will continue to rise.

2. Growing Focus on Water Reuse and Recycling

As water scarcity becomes an increasingly important issue globally, pharmaceutical companies are focusing on water reuse and recycling in their production processes. Water used in non-sterile applications, such as cleaning and cooling, is being treated and reused in a closed-loop system. This not only reduces the environmental impact but also cuts down on operational costs associated with purchasing large volumes of water.

3. Integration of IoT and AI in Water Management Systems

The integration of Internet of Things (IoT) sensors and AI-driven analytics into water management systems is transforming the pharmaceutical water market. IoT devices can continuously monitor water quality in real time, while AI algorithms analyze the data to detect anomalies, predict failures, and optimize the water treatment process. This integration improves operational efficiency, reduces downtime, and ensures that water quality remains compliant with industry standards.

4. Increased Investment in Water Purification Technology

Pharmaceutical companies are increasingly investing in advanced water purification technologies, such as reverse osmosis, distillation, and ultraviolet (UV) sterilization. These technologies are essential to meet the strict water quality requirements in the pharmaceutical industry. Moreover, investment in modular water treatment systems, which offer scalability and flexibility, is becoming more common to meet the growing demand for pharmaceutical-grade water.

5. Rise of Digital Water Treatment Solutions

Digitalization in water treatment is becoming a key trend. Digital water treatment systems use automation and real-time monitoring to optimize water purification and reduce costs. These systems can remotely monitor water quality, detect contaminants, and adjust treatment processes, offering better control over water management. Digitalization is also facilitating remote diagnostics, which is especially beneficial for global pharmaceutical companies operating in multiple regions.

Recent Developments in the Pharmaceutical Water Market

Several recent developments highlight the evolving landscape of the pharmaceutical water market:

-

Increased Regulatory Scrutiny: Regulatory agencies are becoming stricter in terms of water quality standards for pharmaceuticals. For instance, the FDA has released new guidelines regarding water systems for pharmaceutical manufacturers, emphasizing the importance of regular testing, sterilization, and maintenance.

-

Partnerships and Collaborations: Pharmaceutical companies are partnering with water treatment technology providers to develop cutting-edge purification systems. These collaborations are aimed at improving the efficiency of pharmaceutical water production and ensuring the highest standards of purity.

-

Sustainability Initiatives: Many pharmaceutical companies are integrating sustainability into their water management practices. Companies are investing in water recycling and waste management systems to reduce their environmental footprint while meeting growing production demands.

-

Adoption of Smart Water Systems: The rise of smart water management systems that incorporate AI, IoT, and big data analytics is reshaping the industry. These systems not only help optimize water use but also ensure compliance with the ever-increasing regulatory standards for pharmaceutical water.

![¿Cómo puedo contactar con una persona en vivo en los vuelos de Frontier? [Guía paso a paso]](https://timessquarereporter.com/upload/media/posts/2025-06/12/como-puedo-contactar-con-una-persona-en-vivo-en-los-vuelos-de-frontier-guia-paso-a-paso_1749705127-s.jpg)

![How Do I Get to a Live Person at Frontier Flights? [Step-by-Step Guide]](https://timessquarereporter.com/upload/media/posts/2025-06/12/how-do-i-get-to-a-live-person-at-frontier-flights-step-by-step-guide_1749705004-s.jpg)

Comments

0 comment