views

The Role of Mass Spectrometry in Biologics Development

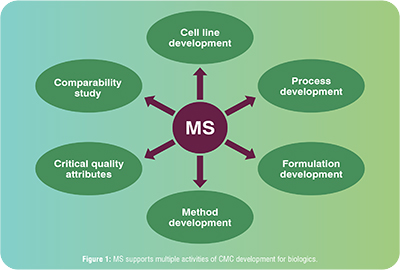

Mass spectrometry (MS) has become an indispensable tool during manufacturing process development, also known as CMC (Chemistry Manufacturing and Controls) development, for biologics. Information about product-related variants (such as post-translational modifications (PTMs)) and process-related impurities (such as host cell proteins (HCPs)) can be extensively characterized by MS to understand process performance and product quality. The in-depth data provided can play a key role in defining and understanding the Critical Quality Attributes (CQAs) which need to be well-controlled by the manufacturing process and closely monitored by the analytical testing panel to ensure specifications are met. MS attribute data is also a key component in regulatory submissions, including the Elucidation of Structure and Manufacturing Process Development (especially process comparability) sections. With recent development of new methods and instrumentation, MS is finding a wider usage in the regulated release testing of Good Manufacturing Practices (GMP)-produced drug substance, such as for identity testing, target attribute or impurity monitoring, or multi-attribute-methods (MAM). State-of-the-art MS technologies also benefit proteomics studies with higher sensitivity, lower detection limit, and faster throughput.

Well-established roles of mass spectrometry (MS) in biologics development

Manufacturing Process Development

After a lead protein design is selected for clinical trials, biologics manufacturing (also known as chemistry manufacturing and control, or CMC) development activities commence. CMC development encompasses the entire manufacturing process of the drug substance (DS) and formulation of the drug product (DP) at a scale and quality sufficient for human use in clinical trials or as a commercial product. The initial application for use of a lead protein in a clinical trial requires the submission of an Investigational New Drug (IND) or Clinical Trial Application (CTA) to the respective government agency where the trial is planned. The process and analytical development teams at the sponsor company ensure the quality and safety of the product to be used for clinical trials by a comprehensive workflow of identifying Critical Quality Attributes (CQAs), setting product specifications as part of a control strategy for ensuring the CQAs are at required levels, and demonstrating process consistency by comparability studies. As shown in Figure 1, MS is a valuable tool supporting most activities of Biologics CMC development, including but not limited to cell line development, process development including upstream (bioreactor expression) and downstream (purification) stages, formulation development of the drug product (the final presentation, including vials and devices, as well as biotherapeutic and excipients), critical quality attribute (CQA) characterization, comparability studies, and any additional studies such as investigations of process outliers or lot failures.

Mass Spectrometry Supports Process and Formulation Development

Mass spectrometry is a versatile tool for answering questions like “What does the molecule look like?”, or more specifically, “what is the amino acid sequence/primary structure of the protein molecule?” Peptide mapping and intact mass are two of the most common approaches for MS assays that support extended characterization of drug candidates. For peptide mapping experiments, protein samples undergo digestion by incubating with protease(s) prior to separation by liquid chromatography (LC) and mass analysis by MS. For intact mass experiments, protein samples do not undergo proteolysis; instead, samples are diluted, and the mass analyzed for the intact molecules or subunits. Intact MS is useful because it quickly verifies the primary sequence and most-abundant post-translational modifications (PTMs) of the protein. The accurate measurement of masses by most modern MS instruments ensures reliable identification of the major component of the drug and most deviations from its expected structure due to the impact on molecular mass of the protein.

MS is used to detect sequence variants (SVs) to support cell line development in the early stage of CMC development. SVs are unintended errors in the amino acid sequence of the biotherapeutic protein caused by substitutions, deletions, and/or insertions of nucleotides in the DNA encoding for our protein within the host cell line.

DNA mutations can result in missense (incorrect amino acid being substituted), non-sense (a truncation site for expression of the protein), or frame shift mutations (where the reading frame shifts, dramatically changing the amino acid sequence), potentially impacting the quality, safety, and efficacy of biotherapeutic proteins. It should be noted that MS cannot detect silent mutations; therefore, SV screening by MS as well as orthogonal nucleotide sequencing methods such as Next Generation Sequencing of mRNA (NGS) or Sanger sequencing of cDNA are routinely performed during the clone selection stage to ensure that the final lead clone used has no encoding mutations. Using both approaches simultaneously is beneficial over nucleotide sequencing approaches alone, as MS provides a direct measure of SV impact on the final protein product, whereas nucleotide approaches may not indicate if the mutant form is expressed or co-purified.

MS also provides valuable insights to support both upstream and downstream manufacturing process development. During upstream development, many bioreactor culture conditions, such as pH or temperature, may lead to differences in analytical attributes of the therapeutic protein, such as the charge profile distribution (measured by isoelectric focusing or ion exchange chromatography). MS can be leveraged to identify the specific modification differences of the therapeutic causing a shift in the profile, such as deamidation of a specific asparagine or modification of the C-terminus of the protein. This knowledge can allow both a quality risk assessment and understanding of the root cause of the difference

Discover more: https://www.pharmafocuseurope.com/research-development/emerging-role-mass-spectrometry

Comments

0 comment