views

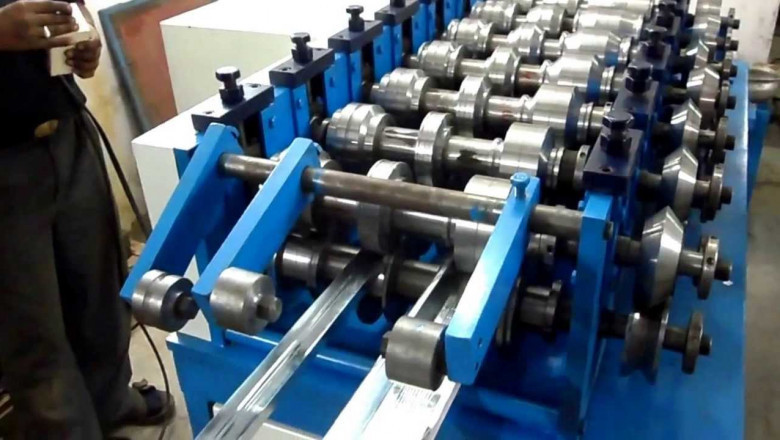

Roll forming machines areused for shaping and forming metal sheets or plates into cylindrical shells by mechanically deforming the metal through a series of rollers. The process involves the progressive bending of flat metal stock by passing it through multiple sets of forming rollers which gradually bend the material into the desired cross-section. Roll forming machines offer benefits such ashigh production rates, tight tolerances, smooth bends, reduced wastage and improved quality. With growing automation and industrialization, there is an increased demand for roll formed parts across various end-use industries like construction, automotive, HVAC ducting etc.

The Global Roll Forming Machine Market is estimated to be valued at US$ 1.3 Billion in 2025 and is expected to exhibit a CAGR of 3.6% over the forecast period 2025-2031.

Key Takeaways

Key players operating in the Roll Forming Machine market are Larsen & Toubro,Samco Machinery, Metform international, Englert Inc, Jingye Machine and Jidet.

Growing construction and infrastructure development activities in emerging economies present significant growth opportunities in the roll forming machines market. Rapid industrialization and demand for pre-engineered metal buildings also support Roll Forming Machine Market Trends.

Adoption of robotic automation and integration of advanced technologies like artificial intelligence, Internet of Things, and predictive maintenance solutions are expected to transform roll forming operations and drive efficiencies.

Market drivers

Increasing construction and infrastructure development projects around the world are a key factor driving demand for roll formed metal products. Rapid urbanization and growth in industrial and commercial construction boost the roll forming machines market. The market is also gaining traction due to rising automotive production and growing need for cost-effective alternatives to welding in various manufacturing industries. Growing focus on optimum resource utilization, reducing wastage and achieving higher throughput will further propel the adoption of roll forming technology in the coming years.

Current Challenges in Roll Forming Machine Market

The roll forming machine market is facing challenges due to the increasing prices of raw materials, especially steel. Steel is the key raw material used in roll forming machines. However, the prices of steel have witnessed a rise in the past year due to lower production and shortage of supply amid the Covid-19 pandemic. Moreover, freight and logistics costs have also increased significantly adding to the overall costs. Higher production costs are putting pressure on margins of roll forming machine manufacturers. Additionally, the supply chain disruptions caused due to lockdowns and restrictions have hampered roll forming machine production and deliveries causing delays in various manufacturing projects. Geopolitical tensions have further exacerbated the supply chain issues making it difficult to predict costs and availability of raw materials.

SWOT Analysis

Strength: Robust demand from the construction and automotive industries which are key end-use segments. Wide range of roll forming applications in metal fabrication.

Weakness: High dependency on economic cycles and investment trends in end-use industries. Rising costs of raw materials and logistics pose margin pressure.

Opportunity: Growth in renewable energy sector to drive demand for roll formed metal components. Expanding applications in HVAC and general engineering applications.

Threats: Increased localization requirements in certain regions pose potential trade barriers. Intense competition from alternative metal forming technologies.

Geographical Regions

In terms of value, North America is currently the largest market for roll forming machines led by strong demand from the US construction industry. Europe is also a major roll forming machine market driven by manufacturing activities in Germany, Italy and other Western European countries. The Asia Pacific region is poised to witness the fastest growth over the coming years due to rising infrastructure spending and expanding manufacturing capabilities in China, India and Southeast Asian economies.

The fastest growing regional market for roll forming machines is expected to be Asia Pacific through 2031 supported by surging construction and automotive production in China and India. Government initiatives to develop infrastructure and boost domestic manufacturing will drive roll forming machine installations across Asia Pacific. In addition, the relocation of manufacturing facilities from developed markets to Asia offers significant opportunities.

Get this Report in Japanese Language:

Get this Report in Korean Language:

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

Comments

0 comment