views

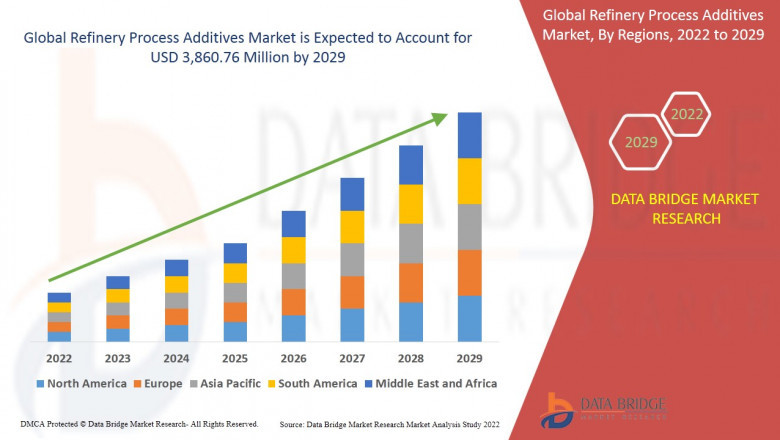

"Global Refinery Process Additives Market - Size, Share, Industry Trends, Demand and Opportunities

Global Refinery Process Additives Market, By Type (Product Quality Improvement Additives, Environmental Protection Additives, Extend Operating Cycle and Reduce Energy Consumption Additives, Raw Oil Quality and Catalytic Activity Improvement Additives, Product Distribution Improvement Additives), Functionality (Demulsifiers, Desalter, Corrosion inhibitors, Defoamer and Others), Application (Gasoline, Aviation fuel, Residual fuel and Others), Process (Distillation, Cracker, Desulfurization Catalytic Reforming and Others), Crude Type (Low Viscosity Crude Oil, Medium Viscosity Crude Oil, Heavy Viscosity Crude Oil)– Industry Trends and Forecast to 2029.

Access Full 350 Pages PDF Report @

https://www.databridgemarketresearch.com/reports/global-refinery-process-additives-market

**Segments**

- Based on type, the global refinery process additives market can be segmented into antioxidants, antifoaming agents, corrosion inhibitors, dehazers, demulsifiers, detergents, dispersants, metal deactivators, and others. Antioxidants are used to prevent oxidation that leads to rust and corrosion. Antifoaming agents help in reducing foam formation during various refinery processes. Corrosion inhibitors are crucial in protecting refinery equipment from degradation due to corrosion. Dehazers assist in removing haze-causing contaminants from petroleum products. Demulsifiers aid in separating water from crude oil. Detergents are additives that prevent carbon deposits in the refinery process. Dispersants help in dispersing solid particles in liquid formulations. Metal deactivators are used to deactivate metal ions present in petroleum products to prevent catalytic reactions. Each type of refinery process additive serves a specific purpose in ensuring the efficiency and durability of refinery operations.

- By application, the market can be categorized into gasoline, diesel, jet fuel, heavy fuel oil, and others. Gasoline additives enhance fuel performance and efficiency, leading to reduced emissions and improved engine longevity. Diesel additives improve cetane number, lubricity, and stability of diesel fuel, ensuring optimal engine performance. Jet fuel additives help in controlling freezing point, thermal stability, and corrosion prevention in aircraft engines. Heavy fuel oil additives assist in managing viscosity, sulfur content, and combustion efficiency in marine engines. The diverse applications of refinery process additives across different fuel types underscore their importance in maintaining fuel quality and operational integrity.

**Market Players**

- Some of the key players in the global refinery process additives market include Afton Chemical, BASF SE, Clariant, Dorf Ketal, Evonik Industries, Chevron Oronite Company LLC, The Lubrizol Corporation, Baker Hughes, a GE company, Lanxess, Albemarle Corporation, and Croda International Plc. These companies are actively involved in research and development activities to introduce innovative refinery process additives that cater to the evolving needs of the petroleum industry. Strategic collaborations, acquisitions, and expansions are common strategies adopted by market players to strengthen their market position and expand their product offerings. The competitive landscape of the global refinery process additives market is characterized by intense competition and a focus on technological advancements and sustainability practices.

https://www.databridgemarketresearch.com/reports/global-refinery-process-additives-marketThe global refinery process additives market is witnessing significant growth driven by the increasing demand for efficient and sustainable refinery operations. With a focus on enhancing fuel quality, maintaining operational integrity, and meeting stringent environmental regulations, the market is poised for continuous expansion. Refinery process additives play a critical role in optimizing refinery processes, improving fuel performance, and ensuring the longevity of equipment. Antioxidants, antifoaming agents, corrosion inhibitors, and other additives cater to specific needs within the refining industry, highlighting the diverse applications and importance of these additives across different fuel types.

Market players in the global refinery process additives industry are actively engaged in research and development initiatives to introduce innovative solutions that align with the evolving requirements of the petroleum sector. Companies such as Afton Chemical, BASF SE, Clariant, and Evonik Industries are investing in technological advancements to enhance product performance and sustainability. Strategic collaborations, acquisitions, and expansions are common strategies employed by key players to strengthen their market presence and diversify their product portfolios. The competitive landscape of the market is characterized by intense competition, prompting companies to focus on differentiation through product innovation and sustainability practices.

As global energy demand continues to rise, the role of refinery process additives in optimizing refinery operations and ensuring fuel quality becomes increasingly essential. The market is anticipated to witness steady growth as the industry seeks solutions to enhance operational efficiency, reduce emissions, and comply with regulatory standards. The adoption of advanced additives across gasoline, diesel, jet fuel, and heavy fuel oil applications underscores the critical role played by refinery process additives in meeting the evolving needs of the petroleum industry. With a strong emphasis on innovation and sustainability, market players are well-positioned to capitalize on opportunities for growth and expansion in the global refinery process additives market.**Segments**

Global Refinery Process [Additives Market](https://www.databridgemarketresearch.com/reports/global-performance-additives-market), By Type (Product Quality Improvement Additives, Environmental Protection Additives, Extend Operating Cycle and Reduce Energy Consumption Additives, Raw Oil Quality and Catalytic Activity Improvement Additives, Product Distribution Improvement Additives), Functionality (Demulsifiers, Desalter, Corrosion inhibitors, Defoamer and Others), Application (Gasoline, Aviation fuel, Residual fuel and Others), Process (Distillation, Cracker, Desulfurization Catalytic Reforming and Others), Crude Type (Low Viscosity Crude Oil, Medium Viscosity Crude Oil, Heavy Viscosity Crude Oil) – Industry Trends and Forecast to 2029.

- Refinery process additives encompass a range of types that cater to specific needs within the refining industry, ensuring operational efficiency, fuel quality enhancement, and equipment longevity. Antioxidants, antifoaming agents, corrosion inhibitors, dehazers, demulsifiers, detergents, dispersants, and metal deactivators play vital roles in different aspects of the refining process, emphasizing the importance of these additives in maintaining operational integrity.

- The market for refinery process additives is segmented by applications across various fuel types such as gasoline, diesel, jet fuel, and heavy fuel oil. These additives provide crucial benefits including enhancing fuel performance, controlling freezing points, managing viscosity, and improving combustion efficiency, underscoring their significance in optimizing fuel quality and meeting industry standards.

Market Players:

Key players in the global refinery process additives market, including Afton Chemical, BASF SE, Clariant, Dorf Ketal, Evonik Industries, Chevron Oronite Company LLC, The Lubrizol Corporation, Baker Hughes, a GE company, Lanxess, Albemarle Corporation, and Croda International Plc, are actively involved in research and development initiatives to introduce innovative solutions and meet the evolving needs of the petroleum sector. These companies focus on technological advancements, sustainability practices, and strategic collaborations to strengthen their market positions and expand their product portfolios.

The competitive landscape of the market is characterized by intense competition, driving companies to differentiate themselves through product innovation and sustainable practices. As the global energy demand continues to rise, refinery process additives play a critical role in optimizing operations, ensuring fuel quality, and meeting regulatory requirements. The market is expected to witness steady growth as the industry seeks solutions to enhance operational efficiency, reduce emissions, and comply with stringent standards.

In conclusion, the global refinery process additives market is dynamic and driven by the imperative need for efficient and sustainable refinery operations. The diverse applications of refinery process additives across different fuel types highlight their importance in maintaining fuel quality, operational integrity, and environmental compliance. Market players continue to focus on innovation, sustainability, and strategic partnerships to capitalize on growth opportunities and address the evolving demands of the petroleum industry.

Table of Content:

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Global Refinery Process Additives Market Landscape

Part 04: Global Refinery Process Additives Market Sizing

Part 05: Global Refinery Process Additives Market Segmentation By Product

Part 06: Five Forces Analysis

Part 07: Customer Landscape

Part 08: Geographic Landscape

Part 09: Decision Framework

Part 10: Drivers and Challenges

Part 11: Market Trends

Part 12: Vendor Landscape

Part 13: Vendor Analysis

Key takeaways from the Refinery Process Additives Market report:

- Detailed considerate of Refinery Process Additives Market-particular drivers, Trends, constraints, Restraints, Opportunities and major micro markets.

- Comprehensive valuation of all prospects and threat in the

- In depth study of industry strategies for growth of the Refinery Process Additives Market-leading players.

- Refinery Process Additives Market latest innovations and major procedures.

- Favorable dip inside Vigorous high-tech and market latest trends remarkable the Market.

- Conclusive study about the growth conspiracy of Refinery Process Additives Market for forthcoming years.

Browse Trending Reports:

Advanced Probe Card Market Size, Share and Trends

Metallized Film Market Size, Share and Trends

Electric Stimulation Devices Market Size, Share and Trends

Hydrotherapy Appliances Market Size, Share and Trends

Friction Feeders Market Size, Share and Trends

Glassine and Glass Proof Packaging Market Size, Share and Trends

Dark Analytics Market Size, Share and Trends

Cervical Dilator Market Size, Share and Trends

Acid Lipase Deficiency Market Size, Share and Trends

Automotive Crank Trigger Market Size, Share and Trends

Conveyor Maintenance Market Size, Share and Trends

Isaac-Mertens Syndrome Market Size, Share and Trends

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Comments

0 comment