views

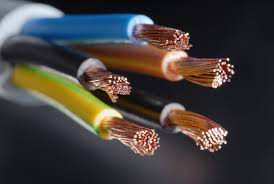

The low voltage cable market, crucial to power distribution and connectivity in homes, commercial complexes, and industrial facilities, is facing multiple hindrances that are restraining its growth trajectory. Despite growing demand driven by urbanization, electrification, and infrastructure development, the industry is contending with several persistent barriers. These include high dependency on volatile raw materials, logistical disruptions, regulatory inconsistencies, and evolving customer demands. Overcoming these hindrances is vital to ensure long-term viability and competitiveness in an increasingly technology-driven global economy.

Raw Material Dependency and Price Volatility

One of the most critical hindrances in the low voltage cable market is the heavy reliance on copper and aluminum, both of which are subject to frequent price fluctuations. These metals form the core of cable conductors, and any global disruption—be it due to mining constraints, political unrest, or currency fluctuations—can inflate manufacturing costs and squeeze profit margins.

Small and mid-sized manufacturers are particularly vulnerable, often unable to absorb the impact or negotiate favorable pricing. This leads to inconsistencies in production planning and delays in fulfilling contracts, creating uncertainty throughout the supply chain.

Complex and Fragmented Regulatory Landscape

The lack of uniform global standards for cable quality, fire resistance, insulation, and environmental compliance creates a major hurdle for international manufacturers. Each country or region typically has its own safety codes and certification protocols, forcing producers to design multiple product variants to meet specific regulatory demands.

This not only increases design and testing costs but also limits economies of scale. For companies aiming to expand across borders, the burden of navigating complex regulatory requirements can deter market entry, delay product launches, and slow growth in new geographies.

Proliferation of Counterfeit Products

Another significant hindrance is the widespread availability of counterfeit and non-compliant cables in developing markets. These inferior products, often sold at lower prices, compromise consumer safety, undermine brand trust, and erode the market share of authentic manufacturers.

Counterfeit cables generally lack proper insulation and do not meet fire safety standards, increasing the risk of accidents. Governments and industry associations have struggled to enforce effective monitoring systems, allowing these products to persist in the supply chain and hinder the overall integrity of the market.

Supply Chain Bottlenecks and Transportation Delays

The globalized supply chain supporting the low voltage cable industry is highly susceptible to disruptions. Events such as the COVID-19 pandemic, trade restrictions, container shortages, and geopolitical tensions have repeatedly led to transportation delays, port congestions, and material shortages.

These supply chain hindrances impact timely production, project execution, and inventory management. Manufacturers are now compelled to diversify sourcing, localize supply chains, or hold larger inventories—all of which add to operational costs and reduce flexibility.

Limited Technological Advancement Among SMEs

While digitalization and automation are reshaping industries, many small and medium-sized enterprises (SMEs) in the low voltage cable sector lag behind in adopting advanced manufacturing technologies. These companies often lack the capital or expertise to invest in innovations like AI-driven quality control, smart inventory systems, or automated testing facilities.

As a result, productivity remains low, and quality inconsistencies persist. Without embracing digital tools, these players struggle to meet evolving customer expectations and face difficulty competing with tech-enabled global manufacturers.

Environmental Pressures and Compliance Costs

Amid rising awareness of climate change and environmental degradation, the low voltage cable industry is under increasing pressure to reduce its carbon footprint and adopt eco-friendly practices. However, compliance with green standards, such as producing halogen-free cables and using recyclable materials, is expensive.

Transitioning to sustainable production methods often requires new equipment, waste treatment systems, and training programs. For many manufacturers, especially in cost-sensitive regions, these requirements pose significant financial and logistical hindrances that delay progress toward sustainability.

Shortage of Skilled Labor

The industry also faces a critical shortage of skilled labor, particularly in technical roles like installation, testing, and advanced design. As experienced workers retire, there is a lack of trained professionals to fill the gap, leading to delays, increased errors, and compromised safety in implementation.

This labor shortage is especially challenging in emerging economies where vocational training in electrical systems and cable engineering is limited. Without investment in education and upskilling, the industry’s capacity to scale operations and meet rising demand remains hindered.

Slow Response to Market Trends

Today’s customers demand cables that are not only functional but also smart, sustainable, and adaptable to new energy applications like electric vehicles, renewable power systems, and data centers. However, many manufacturers are slow to respond to these emerging trends due to a conservative approach to R&D or limited resources.

This sluggishness hampers innovation, reduces competitiveness, and restricts market penetration in high-growth segments. Players who fail to anticipate and align with these trends risk becoming obsolete as customer preferences and technologies continue to evolve.

Conclusion

The low voltage cable market, while poised for long-term demand due to global electrification and infrastructure growth, faces a web of hindrances that stall its progress. From material dependency and regulatory fragmentation to labor shortages and environmental challenges, these issues demand coordinated industry-wide responses. Manufacturers must prioritize modernization, quality assurance, and sustainability while governments and associations work to streamline regulations and enforce safety standards. By proactively addressing these hindrances, the low voltage cable market can achieve greater resilience, competitiveness, and sustainable growth in the years to come.

Comments

0 comment