views

Introduction: Japan Takes the Lead in Smart Warehousing

The Japan Warehouse Robotics Market is no longer a futuristic concept. It has become an immediate reality driven by necessity and enabled by technological excellence. As global supply chains become increasingly complex and consumer expectations continue to evolve, Japan is turning to robotics and artificial intelligence to redefine warehouse operations. The market is predicted to reach USD 939.3 million by 2030, at a CAGR of 16.7% from 2025 to 2030. These advancements are not only improving productivity but also enabling companies to adapt to changing market dynamics with unprecedented agility.

The Urgency of Digital Transformation in Warehousing

Japan’s logistics sector is under pressure from multiple fronts. Rising labor costs, e-commerce expansion, shrinking delivery windows, and urban congestion are forcing companies to rethink traditional warehouse models. Digital transformation, with robotics at its core, is becoming essential for survival. From order sorting and shelf replenishment to palletizing and dispatch, robots are being deployed to perform critical tasks with high precision and minimal error.

Robotics and AI: Building the Smart Warehouse

At the heart of this transformation is the fusion of robotics with artificial intelligence. Unlike earlier systems that followed pre-programmed paths, modern warehouse robots in Japan are learning to navigate dynamic environments using computer vision and machine learning. These robots can adapt to changes in warehouse layout, avoid obstacles in real-time, and optimize their routes for efficiency. AI is also helping in forecasting inventory needs, managing stock levels, and identifying workflow bottlenecks, ensuring that warehouse operations are not only automated but also intelligent and responsive.

Modular and Scalable Solutions for Every Business Size

Japanese companies are recognizing that warehouse automation is not limited to large enterprises. Robotics manufacturers are now offering modular and scalable solutions suitable for small and medium-sized businesses. These solutions allow warehouses to start with a few units of autonomous robots and gradually scale up as demand increases. The flexibility to integrate with existing warehouse management systems (WMS) and enterprise resource planning (ERP) platforms is making robotic adoption more seamless than ever before.

Case Studies: Leading the Way with Robotics

Major logistics firms in Japan, such as Yamato Transport, Nippon Express, and Rakuten, are investing heavily in robotics-driven warehouse facilities. Yamato’s newly launched robotic fulfillment center in Chiba features hundreds of autonomous picking robots that work alongside human supervisors. Rakuten, meanwhile, is deploying drones for internal inventory audits, drastically reducing the time required for stock verification. These case studies reflect the strategic importance companies are placing on automation not just to reduce costs but to gain competitive advantage.

Education, Training, and Workforce Transformation

Contrary to fears of job displacement, the integration of robotics is fostering the creation of new types of employment. Japan is investing in workforce reskilling programs to train technicians and warehouse operators in managing robotic systems. Universities and vocational institutes are offering specialized courses in robotics maintenance and logistics technology. This upskilling initiative is crucial to ensuring a smooth human-robot collaboration and sustainable industry growth.

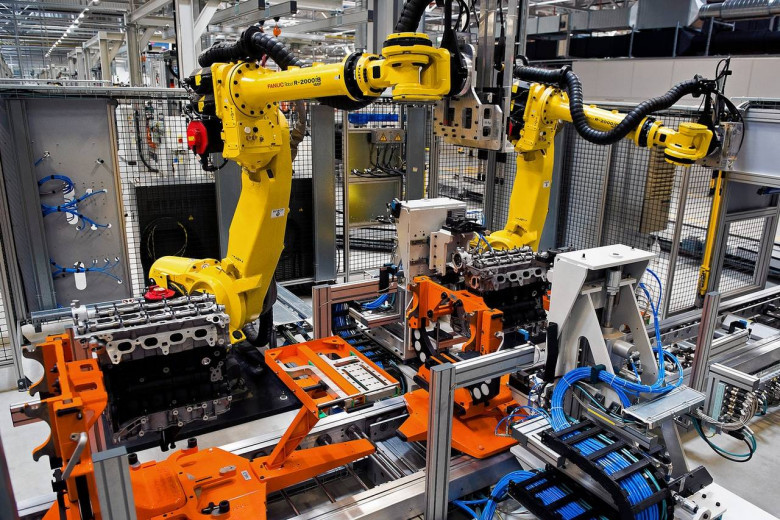

Cross-Industry Applications Expanding Market Reach

Warehouse robotics in Japan is no longer confined to retail or e-commerce. The pharmaceutical sector is adopting robotic solutions to maintain cold chain integrity and ensure precision handling of medical supplies. Automotive companies are utilizing robotics for just-in-time inventory management. The food and beverage industry is implementing robotic sorters to handle perishable goods with minimal human contact. As these use cases expand, the market potential continues to grow across verticals.

Environmental Sustainability Through Automation

One often overlooked benefit of robotics in warehousing is its contribution to environmental goals. Automated systems consume less energy than traditional manual operations and can be programmed for energy efficiency. Robots optimize storage density and reduce the need for excessive lighting or climate control in certain areas. Additionally, the reduction in errors and returns through precise picking and packing leads to lower carbon emissions across the supply chain.

Challenges and Solutions for Broader Implementation

The journey to full-scale automation is not without challenges. Initial investment remains a significant hurdle for many firms. Integration with legacy systems, cybersecurity concerns, and the need for standardized protocols are issues that need to be addressed. However, collaborative efforts between tech providers, government agencies, and logistics firms are paving the way for affordable and secure robotic systems. The development of national guidelines for robotic safety and data privacy is further accelerating trust and adoption.

Looking Ahead: Japan as a Global Leader in Robotic Logistics

Japan’s robust infrastructure, combined with its culture of precision engineering, places it in a strong position to lead the global warehouse robotics industry. The country’s efforts in policy formulation, R&D investment, and public-private collaboration are expected to set global standards for automation excellence. As warehouse robotics continues to evolve, Japan’s innovations will likely serve as a model for other nations seeking to transform their logistics sectors.

Conclusion

The warehouse robotics revolution in Japan is more than a technological upgrade—it is a strategic necessity. Through smart automation and AI-driven solutions, Japanese warehouses are setting benchmarks in speed, accuracy, safety, and sustainability. With continued support from government, academia, and industry, the market is on a trajectory toward long-term success and global influence. Businesses embracing these changes today are laying the foundation for tomorrow’s smart supply chains.