views

Flexible Printed Circuit Boards Market Soars with Miniaturization Technology

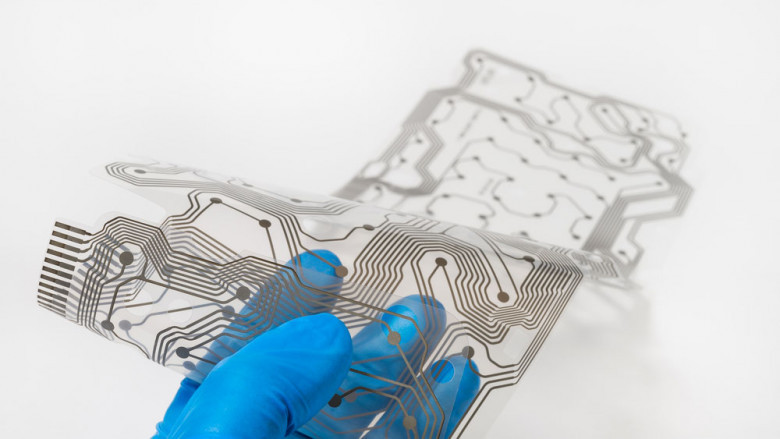

Flexible printed circuit boards (FPCBs) are thin, flexible and lightweight interconnect assemblies crafted from polyimide or polyester substrates with precisely etched copper conductors. Offering superior compactness, flexural endurance and space optimization compared to rigid PCBs, FPCBs enable dynamic bending, folding and 3D configurations across electronics applications—from smartphones and wearables to medical implants and automotive sensors. Their high thermal resistance, improved signal integrity and reduced assembly costs make them ideal for consumer electronics, aerospace, industrial automation and automotive systems.

With OEMs prioritizing device miniaturization, the demand for advanced flexible interconnects has surged, fueling Flexible Printed Circuit Boards Market growth. Innovations in substrate materials and additive manufacturing techniques are enhancing circuit density, reliability and production efficiency. According to market research and market insights, these developments are reshaping market dynamics and expanding the industry scope.

The flexible printed circuit boards market is estimated to be valued at USD 27.02 Bn in 2025 and is expected to reach USD 57.53 Bn by 2032. It is projected to grow at a compound annual growth rate (CAGR) of 11.4% from 2025 to 2032.

Key Takeaways

Key players operating in the Flexible Printed Circuit Boards Market are:

-Samsung Electro-Mechanics

-NOK Corporation

-Flex Ltd.

-Jabil Inc.

-Fujikura Ltd.

These market players hold significant market share and drive innovation through extensive R&D investments. Samsung Electro-Mechanics leads with advanced substrate technologies and high-density interconnect solutions, while NOK Corporation specializes in ultra-thin flex circuits for mobile and wearable devices. Flex Ltd. leverages its global manufacturing footprint to offer scalable FPCB production. Jabil Inc. provides integrated design-to-production services, and Fujikura Ltd. excels in automotive and aerospace-grade flexible interconnects.

Rapid adoption of wearable electronics, IoT devices and electric vehicles presents substantial market opportunities for the Flexible Printed Circuit Boards Market. Growing demand for lightweight, compact and high-performance interconnect solutions in smartphones, tablets, medical implants and automotive LED lighting is creating a broader market scope. Expanding industrial automation, robotics and aerospace sectors also drive FPCB adoption in sensor modules, flexible sensor arrays and high-frequency antenna applications. Additionally, increasing emphasis on miniaturization and multi-layer configurations opens avenues for business growth in next-generation consumer electronics and medical diagnostics. These market opportunities highlight lucrative segments and guide strategic market expansion initiatives.

Miniaturization technology remains the cornerstone technological advancement driving market growth in the Flexible Printed Circuit Boards Market. High-density interconnect (HDI) techniques, advanced flexible substrate materials and micro-via drilling processes enable dramatic increases in circuit density and performance. Additive manufacturing and photolithographic fabrication methods further refine production accuracy and reduce material waste. These technological advancements improve signal integrity, thermal management and reliability in compact electronic assemblies. As OEMs continue to pursue slimmer, more versatile devices, the impact of miniaturization technology on market dynamics and market growth remains profound.

Market Drivers

One of the primary market drivers fueling growth in the Flexible Printed Circuit Boards Market is the rising demand for compact, lightweight and versatile electronic devices. As consumer electronics manufacturers strive for thinner smartphones, foldable gadgets, wearable health monitors and IoT sensors, FPCBs offer unparalleled design flexibility and space optimization. Their ability to conform to complex geometries, absorb mechanical stress and maintain signal integrity under repeated flexing boosts device reliability and user satisfaction. Furthermore, the automotive industry’s shift toward electric vehicles and advanced driver-assistance systems (ADAS) amplifies the need for flexible interconnects in battery modules, infotainment systems and sensor networks. These market drivers underline the pivotal role of FPCBs in enabling product innovation and sustaining long-term market forecast trends.

Current Challenges

Today's dynamic electronics landscape places several key challenges on the flexible printed circuit boards sector. One critical hurdle is the increasing demand for miniaturization and high-density interconnects, which requires advanced materials with superior thermal stability and signal integrity. R&D teams must continuously innovate to balance flexibility with reliability under mechanical stress, driving up costs and extending product development cycles.

Supply chain volatility poses another significant barrier. Fluctuations in raw material availability, especially specialized polyimides and conductive adhesives, lead to unpredictable lead times and pricing pressure. This contributes to tighter profit margins and necessitates more robust risk management frameworks within market players. Regulatory compliance and environmental considerations add further complexity, as manufacturers need to adapt to varying regional safety and chemical restrictions without compromising performance.

Moreover, intense price competition and fragmentation among diversified end-use segments—such as automotive electronics, wearables, and medical devices—introduce market restraints. Each sector applies unique performance requirements, making it challenging to develop one-size-fits-all manufacturing processes. Understanding shifting market trends through comprehensive market research is essential for prioritizing R&D, while in-depth market insights can guide investment decisions. Spotting emerging market opportunities remains critical, yet often underutilized given these technical and economic barriers. Additionally, the need to integrate printed circuit solutions with flexible displays and sensors amplifies design complexity, requiring cross-disciplinary collaboration across mechanical, electrical, and materials engineering teams. Without streamlined design-for-manufacturing protocols, time-to-market can suffer, undermining competitive positioning within evolving market dynamics.

SWOT Analysis

Strength: The flexible printed circuit boards market benefits from its inherent versatility and superior bending performance, enabling seamless integration in compact electronic designs. Its ability to reduce mass and space in wearables and portable devices gives firms an edge in product differentiation and market share.

Weakness: Production costs remain relatively high compared to rigid alternatives, which may deter cost-sensitive customers and restrict large-scale adoption. Additionally, complex, customized designs often involve lengthy setup times and specialized tooling, hampering rapid prototyping and flexible manufacturing.

Opportunity: Rising demand for IoT-enabled devices presents avenues to embed flexible circuits in sensor hubs and smart textiles, creating new market opportunities across consumer electronics. Furthermore, the growing electric vehicle sector requires lightweight, compact interconnect solutions, opening doors for collaborative innovation and expanded revenue streams.

Threats: Volatile raw material prices for polyimide films and copper foils can compress margins and disrupt supply continuity, acting as significant market restraints. Competition from emerging rigid-flex technologies and alternative interconnect methods may erode industry share and challenge future market growth.

Geographical Regions

Asia-Pacific leads in terms of value concentration, anchored by large electronics manufacturing hubs in China, Japan, and South Korea. Continuous investment in advanced fabrication facilities and favorable regulatory frameworks have amplified the region’s market share. North America and Europe also account for substantial industry revenue, driven by strong demand in automotive electronics and medical devices. The United States and Germany serve as key centers of innovation, where established supply chains and advanced quality standards support high-value production.

Meanwhile, Middle East & Africa (MEA) is emerging as the fastest growing region, fueled by expanding telecommunications infrastructure and renewable energy projects that rely on flexible circuitry. Southeast Asian markets—particularly Vietnam and Malaysia—are also experiencing rapid growth as foreign electronics companies diversify their manufacturing bases. Market forecasts highlight these regions’ potential to outpace mature markets, driven by rising local market segments in automotive electronics, consumer wearables, and IoT-enabled solutions.

‣ Get this Report in Japanese Language: フレキシブルプリント基板市場

‣ Get this Report in Korean Language: 유연인쇄회로기판시장

‣ Read More Related Articles- South Korea Emerging as Printed Electronics Leader

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)