views

In the realm of materials science, few innovations have captured the imagination and potential of researchers and industries alike quite like nanofibers. These incredibly thin fibers, with diameters measuring less than 100 nanometers, are at the forefront of technological advancements across various sectors. From healthcare and electronics to environmental protection and energy storage, nanofibers are revolutionizing the way we approach material design and functionality. Their unique properties, including high surface area-to-volume ratio, exceptional strength, and versatility in composition, make them ideal candidates for a wide range of applications. As we delve deeper into the world of nanofibers, we'll explore their production methods, current applications, and the promising future they hold for scientific and industrial progress.

The Science Behind Nanofibers

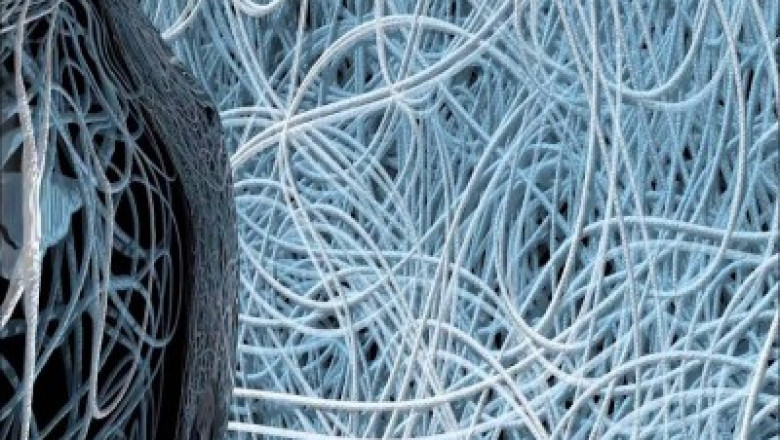

At its core, a Nanofiber is a fiber with a diameter on the nanoscale, typically ranging from 1 to 100 nanometers. To put this into perspective, a human hair is approximately 80,000 to 100,000 nanometers in diameter. The microscopic nature of nanofibers grants them extraordinary properties that set them apart from conventional materials. Their immense surface area relative to their volume allows for enhanced reactivity and interaction with their surroundings. This characteristic makes nanofibers particularly useful in applications requiring high levels of absorption, filtration, or catalytic activity.

Nanofibers can be produced from a variety of materials, including polymers, ceramics, and composites. The choice of material depends on the intended application and desired properties. For instance, polymer nanofibers are often used in tissue engineering and drug delivery systems due to their biocompatibility, while ceramic nanofibers find applications in high-temperature environments and advanced electronics.

Production Techniques: From Lab to Industry

The production of nanofibers has evolved significantly since their discovery, with several methods now available for both laboratory and industrial-scale manufacturing. The most common techniques include electrospinning, melt blowing, and phase separation.

Electrospinning is perhaps the most widely used method for nanofiber production. This process involves applying a high voltage to a polymer solution or melt, causing it to form a thin jet that is then collected on a grounded surface. As the jet travels through the air, the solvent evaporates or the melt solidifies, resulting in ultra-thin fibers. Electrospinning offers excellent control over fiber diameter and orientation, making it ideal for producing nanofibers with specific properties.

Melt blowing, on the other hand, is a technique more suited to large-scale production. It involves extruding molten polymer through small nozzles surrounded by high-velocity hot air. The air stream attenuates the molten fibers, creating nanofibers as they cool and solidify. While melt blowing offers higher production rates, it generally provides less control over fiber properties compared to electrospinning.

Phase separation is another method used to produce nanofibers, particularly for creating 3D nanofiber scaffolds. This technique involves dissolving a polymer in a solvent, inducing phase separation through cooling or the addition of a non-solvent, and then removing the solvent phase to leave behind a nanofiber network.

As research in nanofiber production continues, new methods are being developed to improve efficiency, scalability, and control over fiber properties. These advancements are crucial for bridging the gap between laboratory innovations and industrial applications.

Applications Across Industries

The versatility of nanofibers has led to their adoption in a wide range of industries, each leveraging the unique properties of these materials to solve complex challenges and improve existing technologies.

In the healthcare sector, nanofibers are making significant strides in tissue engineering, wound healing, and drug delivery. Nanofiber scaffolds provide an ideal environment for cell growth and tissue regeneration, mimicking the structure of the extracellular matrix. In wound dressing applications, nanofiber-based materials offer superior absorption capabilities and can be infused with antimicrobial agents to prevent infection. For drug delivery, nanofibers can be designed to release medications in a controlled manner, improving efficacy and reducing side effects.

The environmental industry has embraced nanofibers for their exceptional filtration properties. Nanofiber membranes are being used in air and water purification systems, capable of removing particles and contaminants at a much smaller scale than traditional filters. This technology is particularly promising for addressing global challenges in clean water access and air pollution

Get more insights on, Nanofiber

Get This Report in Japanese Language: ナノファイバー

Get This Report in Korean Language: 나노섬유

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

Comments

0 comment