views

paver block making machine in India

fly ash brick making machine in India

In the ever-evolving construction industry, sustainable and cost-effective building materials have become increasingly important. Fly ash bricks have emerged as a popular alternative to traditional clay bricks, offering numerous advantages in terms of strength, durability, and environmental impact. As the demand for these eco-friendly bricks grows, so does the need for efficient and reliable manufacturing equipment. This is where BTM Product steps in, providing cutting-edge fly ash brick making machine in India and paver block making machine in India that are revolutionizing the industry.

The Rise of Fly Ash Bricks

Before delving into the specifics of fly ash brick making machines, it's essential to understand the significance of fly ash bricks themselves. These innovative building materials are made from a mixture of fly ash (a byproduct of coal combustion), cement, sand, and water. The result is a brick that offers several advantages over traditional clay bricks:

1. Environmental friendliness: Fly ash bricks utilize industrial waste, reducing the need for clay excavation and helping to conserve natural resources.

2. Energy efficiency: The production of fly ash bricks requires less energy compared to conventional bricks, contributing to a lower carbon footprint.

3. Strength and durability: These bricks often exhibit higher compressive strength and better resistance to weathering than their clay counterparts.

4. Cost-effectiveness: The use of readily available fly ash as a primary component helps reduce overall production costs.

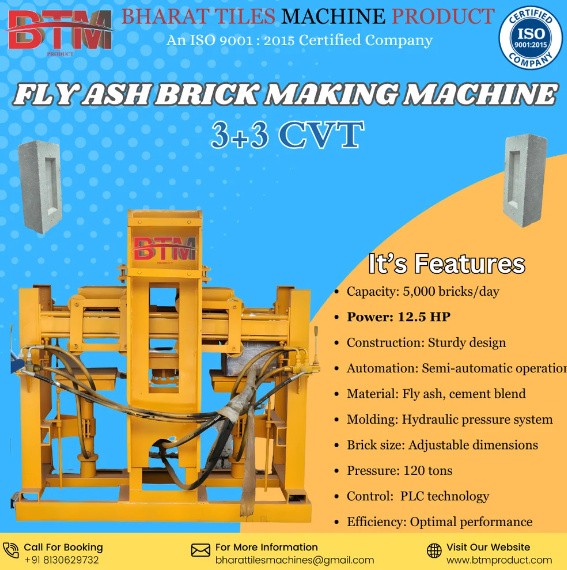

Key Features of BTM Product's Fly Ash Brick Making Machines

BTM Product has established itself as a leader in the manufacture of high-quality fly ash brick making machines in India. Let's explore the key features that set their equipment apart:

1. Advanced Hydraulic System

The heart of BTM Product's fly ash brick making machine is its state-of-the-art hydraulic system. This powerful mechanism ensures:

- Consistent pressure distribution for uniform brick quality

- Reduced energy consumption compared to mechanical systems

- Lower maintenance requirements and increased longevity

2. Precision Mold Design

The molds used in BTM Product's machines are engineered for optimal performance:

- Made from high-grade steel for durability and longevity

- Precision-crafted to ensure consistent brick dimensions

- Easy to clean and maintain, reducing downtime between production cycles

3. Automated Control Systems

Modern automation is a hallmark of BTM Product's fly ash brick making machine in India:

- PLC-based control systems for precise operation

- User-friendly interfaces for easy machine operation

- Real-time monitoring and adjustment capabilities

4. Versatile Production Capabilities

These machines are designed to meet diverse production needs:

- Ability to produce various brick sizes and shapes

- Quick mold change mechanisms for efficient production shifts

- Capacity to handle different raw material compositions

5. Dust Suppression Technology

Recognizing the importance of worker safety and environmental protection, BTM Product incorporates advanced dust suppression systems:

- Minimizes airborne particles during the production process

- Creates a cleaner and safer working environment

- Reduces material wastage, improving overall efficiency

Benefits of Investing in BTM Product's Fly Ash Brick Making Machines

The advantages of choosing BTM Product's equipment extend far beyond the machine's features. Let's examine the broader benefits for businesses:

1. Increased Production Efficiency

- High output capacity to meet growing market demands

- Reduced labor requirements through automation

- Consistent quality production, minimizing rejects and waste

2. Cost-Effectiveness

- Lower operating costs due to energy-efficient design

- Reduced maintenance expenses thanks to durable construction

- Potential for higher profit margins through improved productivity

3. Versatility in Product Range

- Ability to produce not only fly ash bricks but also interlocking tiles making machine in India and paver block making machine in India

- Flexibility to cater to various market segments and customer requirements

4. Enhanced Product Quality

- Precise control over brick density and strength

- Uniform appearance and dimensions for professional results

- Improved customer satisfaction and repeat business

5. Eco-Friendly Operations

- Supports the production of sustainable building materials

- Aligns with green building initiatives and regulations

- Potential for carbon credit benefits in some regions

6. Technical Support and Training

- Comprehensive operator training provided by BTM Product

- Ongoing technical support for troubleshooting and optimization

- Regular updates and improvements to machine software

Expanding Your Product Line: Interlocking Tiles and Paver Blocks

While fly ash bricks are a core product, BTM Product's machines offer the versatility to expand into other lucrative markets. The interlocking tiles making machine in India and paver block making machine in India are popular additions to many manufacturing setups.

Interlocking Tiles:

- Ideal for outdoor spaces, pathways, and decorative applications

- Offers excellent water drainage and easy installation

- Can be produced in various colors and patterns

Paver Blocks:

- Widely used in landscaping, driveways, and commercial spaces

- Known for their durability and load-bearing capacity

- Available in multiple shapes and sizes to suit different design requirements

By investing in a multi-purpose machine from BTM Product, manufacturers can diversify their product offerings and tap into new market segments without significant additional investment.

Case Studies: Success Stories with BTM Product's Machines

To illustrate the real-world impact of BTM Product's fly ash brick making machines, let's look at a couple of brief case studies:

1. Urban Development Project in Mumbai

A construction company tasked with providing sustainable building materials for a large-scale urban development project chose BTM Product's fly ash brick making machine in India. The result:

- 30% increase in daily production capacity

- 15% reduction in overall production costs

- Consistent brick quality that met stringent project specifications

2. Rural Housing Initiative in Rajasthan

A government-backed rural housing program required a reliable source of affordable building materials. After implementing BTM Product's machine:

- Local job creation through the establishment of a brick manufacturing unit

- 40% decrease in brick transportation costs due to on-site production

- Improved housing quality and durability for rural residents

Future Trends and Innovations

As the construction industry continues to evolve, BTM Product remains at the forefront of innovation in fly ash brick making technology. Some emerging trends and developments to watch for include:

- Integration of IoT (Internet of Things) for remote monitoring and predictive maintenance

- Enhanced energy recovery systems to further reduce power consumption

- Development of new mold designs for specialized brick applications

- Incorporation of recycled materials beyond fly ash for even greener production

Conclusion

The fly ash brick making machine in India has become an indispensable tool for modern construction material manufacturers. BTM Product's cutting-edge equipment offers a perfect blend of efficiency, quality, and sustainability. By investing in these advanced machines, businesses can not only meet the growing demand for eco-friendly building materials but also position themselves as industry leaders in sustainable construction practices.

Whether you're looking to start a new manufacturing venture or upgrade your existing production line, BTM Product's range of fly ash brick making machine in India, interlocking tiles making machine in India, and paver block making machine in India provide the versatility and reliability needed to succeed in today's competitive market.

As we move towards a more sustainable future, the role of innovative manufacturing solutions like those offered by BTM Product will only become more critical. By embracing these technologies, we can build a stronger, more resilient, and environmentally conscious construction industry for generations to come.

Comments

0 comment