views

"Global High Temperature Composite Resin Market - Industry Trends and Forecast to 2029

Global High Temperature Composite Resin Market, By Resin Type (BMI, Cyanate Ester, Polyimide, Epoxy, Acrylic, Cyanate Ester, Thermoplastics and Others), Manufacturing Process (Prepreg Layup, RTM and Others), End User (Aerospace and Defense, Marine, Automotive, Electrical and Electronics and Others), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of the Middle East and Africa) Industry Trends and Forecast to 2029.

Access Full 350 Pages PDF Report @

https://www.databridgemarketresearch.com/reports/global-high-temperature-composite-resin-market

**Segments**

- By Resin Type: Phenolic Resin, Epoxy Resin, Polyimide Resin, Cyanate Ester Resin, BMI Resin, Others

- By Manufacturing Process: Lay-Up, Filament Winding, Injection Molding, Pultrusion, Compression Molding, Resin Transfer Molding, Others

- By End-Use Industry: Aerospace & Defense, Transportation, Electrical & Electronics, Renewable Energy, Others

- By Region: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa

High-temperature composite resins are witnessing a surge in demand due to their superior thermal resistance properties, making them ideal for applications requiring resistance to extreme heat conditions. The market is segmented based on resin type, manufacturing process, end-use industry, and region. In terms of resin type, phenolic resin, epoxy resin, polyimide resin, cyanate ester resin, BMI resin, and others are the key segments. When considering the manufacturing process, segments include lay-up, filament winding, injection molding, pultrusion, compression molding, resin transfer molding, and others. The end-use industry segmentation comprises aerospace & defense, transportation, electrical & electronics, renewable energy, and others. Geographically, the market is divided into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

**Market Players**

- Huntsman International LLC

- Hexion

- Lonza

- Sumitomo Bakelite Co., Ltd.

- Evonik Industries AG

- Hexcel Corporation

- DIC CORPORATION

- was a prominent player in the high-temperature composite resin market. The company offers a comprehensive range of products to cater to various industry verticals. Hexion focuses on innovation and strategic partnerships to enhance its market presence and meet customer demands effectively. Lonza is another key player known for its high-quality composite resin offerings that cater to the aerospace and defense industry's stringent requirements. Their strong focus on research and development and sustainability initiatives further solidify their position in the market. Sumitomo Bakelite Co., Ltd., with its wide product portfolio and global presence, remains competitive in the market. Evonik Industries AG is a leading player known for its cutting-edge technologies and commitment to sustainability, driving its growth in the high-temperature composite resin market. Hexcel Corporation, DIC Corporation, and show significant presence in the market with their diverse product offerings and strategic initiatives driving market growth.

https://www.databridgemarketresearch.com/reports/global-high-temperature-composite-resin-marketThe global high-temperature composite resin market is experiencing substantial growth, driven by the increasing demand for materials with superior thermal resistance properties. Phenolic resin, epoxy resin, polyimide resin, cyanate ester resin, BMI resin, and other resin types are key segments in the market, each offering unique advantages for various applications. Phenolic resin stands out for its excellent flame retardant and heat-resistant properties, making it a popular choice in the aerospace and transportation industries. Epoxy resin is valued for its exceptional adhesive properties and versatility across different manufacturing processes. Polyimide resin is known for its high-temperature stability and mechanical strength, making it ideal for demanding applications in the electrical and electronics sector. The market players are continuously focusing on innovation to meet the evolving needs of end-users and gain a competitive edge in the market.

In terms of manufacturing processes, lay-up, filament winding, injection molding, pultrusion, compression molding, resin transfer molding, and other techniques play crucial roles in the production of high-temperature composite resins. Each process offers unique advantages in terms of cost-effectiveness, production efficiency, and product quality. For instance, lay-up is a widely used process that allows for the creation of complex shapes with high fiber content, making it suitable for aerospace and defense applications. Filament winding is preferred for producing cylindrical structures with high strength-to-weight ratios, making it ideal for pressure vessels in various industries. Injection molding is commonly used for high-volume production of intricate parts with tight tolerances, while pultrusion enables the continuous production of composite profiles with consistent mechanical properties.

The end-use industries driving the demand for high-temperature composite resins include aerospace & defense, transportation, electrical & electronics, renewable energy, and others. The aerospace and defense sector requires lightweight materials with high strength and durability to enhance fuel efficiency and performance. Transportation applications demand materials that can withstand rigorous environmental conditions and mechanical stresses. The electrical and electronics industry relies on high-temperature composite resins for insulation and protection in a wide range of electronic components. The renewable energy sector is increasingly adopting composite materials for wind turbine blades, solar panels, and other sustainable energy applications.

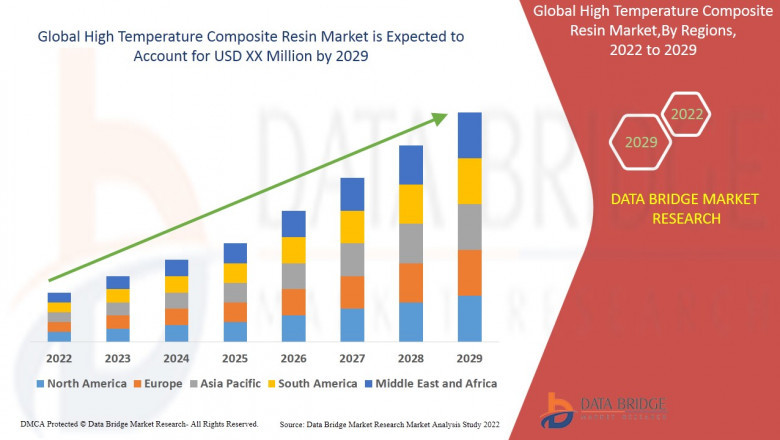

Geographically, North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa are the key regions driving the growth of the high-temperature composite resin market. North America and Europe have well-established aerospace and defense industries that drive the demand for advanced composite materials. Asia-Pacific is witnessing rapid industrialization and infrastructure development, leading to increased adoption of high-temperature composite resins in various end-use sectors. Latin America and the Middle East & Africa are also emerging markets with significant growth opportunities for market players looking to expand their presence globally.

In conclusion, the global high-temperature composite resin market is witnessing robust growth driven by the increasing demand for advanced materials with superior thermal resistance properties. Phenolic resin, epoxy resin, polyimide resin, and other resin types cater to diverse industry needs, while different manufacturing processes offer unique advantages in terms of production efficiency and product performance. With key players like Huntsman International LLC, Lonza, Evonik Industries AG, and others leading the market with innovative solutions and strategic initiatives, the high-temperature composite resin market is poised for continued expansion and technological advancement in the coming years.**Segments**

Global High Temperature Composite Resin Market, By Resin Type (BMI, Cyanate Ester, Polyimide, Epoxy, Acrylic, Cyanate Ester, Thermoplastics and Others), Manufacturing Process (Prepreg Layup, RTM and Others), End User (Aerospace and Defense, Marine, Automotive, Electrical and Electronics and Others), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of the Middle East and Africa) Industry Trends and Forecast to 2029.

The global high-temperature composite resin market is experiencing significant growth fueled by the rising demand for materials with superior thermal resistance properties. Phenolic resin, epoxy resin, polyimide resin, cyanate ester resin, BMI resin, and other resin types play crucial roles in catering to various industry requirements. Phenolic resin, known for its excellent flame retardant and heat-resistant properties, finds extensive use in aerospace and transportation applications. Epoxy resin, valued for its exceptional adhesive properties, versatility across manufacturing processes, and polyimide resin, acknowledged for high-temperature stability and mechanical strength, are preferred choices in sectors like electrical and electronics. Each resin type offers unique advantages, contributing to the diverse applications of high-temperature composite resins across industries.

On the manufacturing process front, techniques such as lay-up, filament winding, injection molding, pultrusion, compression molding, and resin transfer molding are instrumental in producing high-temperature composite resins efficiently. Lay-up is widely employed for creating complex shapes with high fiber content, making it suitable for aerospace and defense applications. Filament winding excels in producing cylindrical structures with high strength-to-weight ratios, ideal for pressure vessels in various industries. Injection molding is favored for high-volume production of intricate parts with tight tolerances, while pultrusion enables continuous production of composite profiles with consistent mechanical properties. Each manufacturing process offers specific advantages in terms of cost-effectiveness, production efficiency, and product quality, catering to diverse industry needs.

In the realm of end-use industries, aerospace & defense, transportation, electrical & electronics, renewable energy, and others are the key sectors propelling the demand for high-temperature composite resins. The aerospace and defense industry necessitates lightweight materials with high strength and durability for enhanced fuel efficiency and performance. Transportation applications require materials capable of withstanding harsh environmental conditions and mechanical stresses. The electrical and electronics sector relies on high-temperature composite resins for insulation and protection across a wide range of electronic components. The renewable energy industry is increasingly adopting composite materials for sustainable energy applications like wind turbine blades and solar panels.

Geographically, North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa are the primary regions driving the growth of the high-temperature composite resin market. North America and Europe, with established aerospace and defense industries, exhibit substantial demand for advanced composite materials. Asia-Pacific's rapid industrialization and infrastructure development are fueling the adoption of high-temperature composite resins in various sectors, creating growth opportunities for market players. Latin America and the Middle East & Africa present emerging markets with significant potential for expansion, attracting companies looking to strengthen their global presence.

In conclusion, the global high-temperature composite resin market is flourishing on the back of increasing demand for advanced materials with exceptional thermal resistance properties. With key players like Huntsman International LLC, Lonza, Evonik Industries AG, and others at the forefront, the market is witnessing continuous innovation and strategic initiatives to address evolving end-user needs and maintain a competitive edge. The ongoing focus on sustainability, technological advancements, and industry-specific applications is poised to drive further growth and development in the high-temperature composite resin market in the upcoming years.

Highlights of TOC:

Chapter 1: Market overview

Chapter 2: Global High Temperature Composite Resin Market

Chapter 3: Regional analysis of the Global High Temperature Composite Resin Market industry

Chapter 4: High Temperature Composite Resin Market segmentation based on types and applications

Chapter 5: Revenue analysis based on types and applications

Chapter 6: Market share

Chapter 7: Competitive Landscape

Chapter 8: Drivers, Restraints, Challenges, and Opportunities

Chapter 9: Gross Margin and Price Analysis

Countries Studied:

- North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

- Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

- Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

- Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Browse Trending Reports:

Asia Pacific Menstrual Cramps Treatment Market

Europe Commercial Cleaning Equipment Market

Europe Quantum Computing Market

India Blood Gas Analyzer Market

Middle East And Africa Commercial Cleaning Equipment Market

Middle East And Africa Neurosurgery Market

Middle East And Africa Sports Medicine Market

Middle East And Africa Vaccines Market

Nigeria Starch Processing Market

North America Menstrual Cramps Treatment Market

North America Neurosurgery Market

Functional Confectionery Market

Menstrual Cramps Treatment Market

Over The Counter Probiotic Supplements Market

Polycystic Kidney Disease Adpkd Market

Private Label Food And Beverage Market

Wireless Medical Device Connectivity Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: corporatesales@databridgemarketresearch.com"

Comments

0 comment